How to Replace Bobbin Winder on Brother Sewing Machine

For the avid sewer, nothing frustrates the creative process more than a malfunctioning sewing machine.Manufacturers, such as Brother, produce a variety of sewing machines, including models with integrated bobbin winders. Replacing the winder is one of the more common routine maintenance tasks. It is important to maintain the winder and ensure that it is properly installed and functioning, because replacing the bobbin winder can sometimes be difficult for a novice.

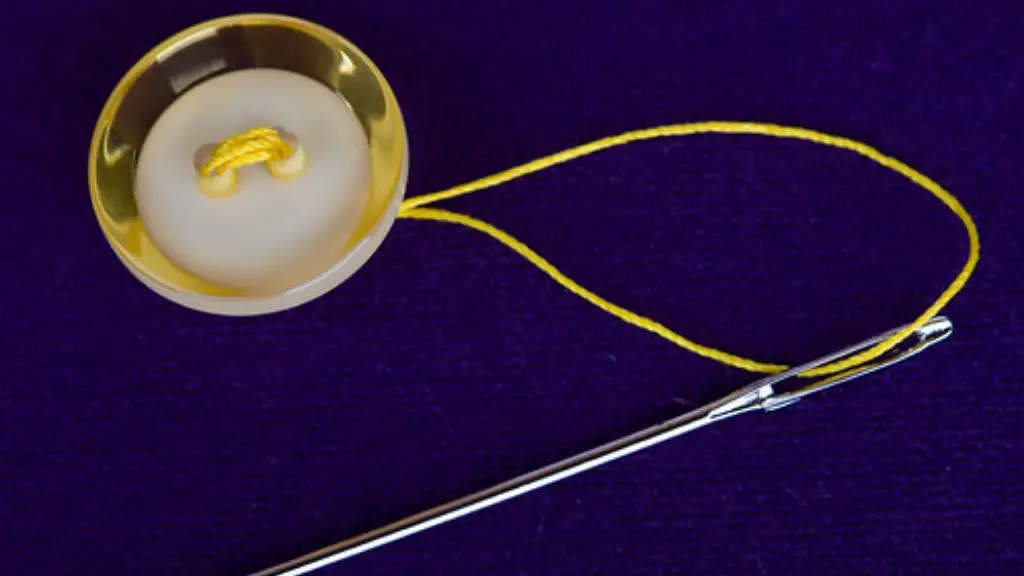

First, it is important to understand the purpose of the bobbin winder: it creates a secure, even tension that uniformly winds thread onto the bobbin, preventing it from becoming tangled or loose. This ensures that your project has an even, consistent stitch. Without it, small tangles and knots can disrupt the entire process. Thankfully, replacing the winder is not an overly complicated task.

Begin by unplugging the machine and removing the arm cover panel. Next, locate the bobbin winder. It should look similar to a tiny wheel mounted to the device, with a small post running off its side. Make sure that the power is off and the machine is unplugged, as it can be hazardous to tinker around with live electricity.

The bobbin winder comes with two small screws. Unscrew them, then take the winder off the post. At this point, installation of the new winder is a piece of cake: simply align the new winder with the post and screw it in.

The only other step is to set the winder tension adjustment. To do that, locate the tension disc; it is placed on the inside side of the bobbin winder. It has a small plastic piece that is accessible and can be turned with a finger to adjust the bobbin winder tension.

Most Brother sewing machines have electric-powered bobbin winders, making routine maintenance and replacements a breeze. It is still important to seek the advice of a professional, when in doubt, as electrical repairs must always be done with the utmost care.

Adjusting the Bobbin Winder Speed

The speed of a bobbin winder is important, as it affects how quickly and evenly the thread is wound onto the bobbin. With a Brother sewing machine, the speed of the bobbin winder can be adjusted with a few simple steps.

Begin by unplugging the machine, then locate the bobbin winder speed dial. It is normally located on the inside portion of the winder, beside the tension disc. With this dial, the speed of the winder can be adjusted from low to high for any given project.

Next, on the same side of the machine as the tension disc, locate the thread tension adjustment dial. This allows the user to adjust the thread tension according to the project, such as a dress shirt or skirt. To determine the proper thread tension, the user should consult their machine’s manual, as the tension will vary based on the type of material and thread being used.

Different projects will require different settings. For instance, light materials require lower tension than heavier materials. Once the proper speed and tension has been determined, the user need only set the dials as desired and enjoy consistently even stitching in their projects.

Maintaining the Bobbin Winder

For any sewing machine, preventive maintenance is key. On Brother sewing machines, the bobbin winder should be regularly maintained, as it is likely to be one of the more frequently used features.

To begin, always use the correct kind of thread for your machine and project. Incorrectly sized thread can increase friction and cause overheating, leading to irregularities in the bobbin winder.

Also, it is important to use the correct tension for your project. Too much tension can cause the bobbin winder to become erratic and loose, leading to uneven stitches. Regular tension adjustments can help ensure that the bobbin winder stays in top condition.

Furthermore, the user should be aware of the bobbin winder’s parts. If anything appears clogged or out of place, it should be cleaned or replaced immediately.

Lastly, the user should clean the bobbin winder regularly. This will help prevent dirt and debris from becoming lodged in the winder mechanism and causing it to malfunction, potentially resulting in an uneven stitch or inefficient performance.

Troubleshooting the Bobbin Winder

If the user’s thread winds unevenly or knots up, it is likely due to a problem with the bobbin winder, such as incorrect tension or incorrect thread. Thankfully, most minor threading issues can be easily solved by troubleshooting and making the necessary adjustments.

First and foremost, the user should check the tension. If the tension is too tight, the thread may become knotted. If it is too loose, the thread will be uneven. To determine the correct tension, consult the sewing machine’s manual.

The user should also be sure to use the correct type of thread for the project. Threads that are too thin may knot on the bobbin winder, resulting in an uneven stitch. If the thread is too thick, it will tangle as it winds around the bobbin.

The user should also check the bobbin winder for any signs of damage. If the winder is cracked, worn, or clogged with dirt and debris, it should be replaced immediately. It is also important to check for any clogs in the winding mechanism, as these can cause thread jams or uneven stitches.

If the issue is not caused by any of these factors, it is best to seek the advice of a professional. With proper maintenance and troubleshooting, the user should be able to keep the bobbin winder of their Brother sewing machine operating smoothly for years to come.

Common Problems and Solutions

Common issues when dealing with the bobbin winder of a Brother sewing machine include adhesive buildup on the bobbin well, threading issues, and fabric tugging. The first two can be quickly solved with a few simple steps.

For cleaning out the bobbin well of adhesive buildup, the user should unplug their machine and remove the bobbin plate. To clean it, they can use a non-abrasive cloth and a mild sewing machine oil. Once the bobbin plate is clean and clear, replace it and test the machine with a scrap piece of fabric.

If the thread continues to get caught in the bobbin bobbin wheel, the user should ensure that the thread is properly fed through the machine. Start at the spool, going through the thread guides, then presser foot, and finally through the needle. Be sure to double-check the user’s machine’s manual for specific instructions in threading the machine.

The most common issue when dealing with a Brother sewing machine is fabric tugging. This is usually caused by an ill-fitted or incorrectly tensioned bobbin case. To solve this problem, the user should check the bobbin case’s tension by turning the dial clockwise. If that does not solve the problem, they should seek the advice of a professional.

Conclusion

Replacing and maintaining the bobbin winder of a Brother sewing machine is not difficult, but it is important to do so correctly. With the proper maintenance and care, the user should be able to keep their machine functioning properly and protect their projects from uneven stitching and unwanted knots. It is important to understand how the various features of the machine work together and the proper methods for adjusting and repairing the bobbin winder. With the right knowledge, anyone can be a master seamstress in no time.