The Tension Assembly

The tension assembly on a sewing machine is a complex part of the machine and one that requires careful attention. It is the mechanism that helps keep the fabric from slipping when the needle is stitching. When the tension assembly breaks, it can make sewing difficult to impossible. Understanding how to replace a tension assembly on a sewing machine can help save a lot of time and effort.

Tools Needed

Changing out the tension assembly on a sewing machine requires a few tools. Most sewing machines, whether manual or electric, come standard with a few allen wrenches, so the first tool you will need is the right size allen wrench. You will also need a pair of needle-nose pliers, a Philips screwdriver, and a small hammer. Having these tools on hand means that you won’t have to rush off to the store if something unexpectedly breaks on your sewing machine.

Removing the Old Tension Assembly

Before you can replace the tension assembly on the sewing machine, you need to remove the old one. The old one will likely be held in place with a few small screws. Use the small Phillips-head screwdriver to carefully remove the screws. When the screws have been removed, the old tension assembly will be loose and easy to pull out. Use the needle-nose pliers if the assembly gets stuck.

Installing the New Tension Assembly

Installing the new tension assembly is fairly straightforward. First, make sure that the new assembly is the correct size and shape for your machine. Then, place the new assembly in position and use the allen wrench to secure it. Make sure that the allen wrench is tightening the assembly correctly. If it is too tight, it can cause the machine to malfunction. A hammer can also be used to ensure that the assembly is tightened properly.

Testing the Tension Assembly

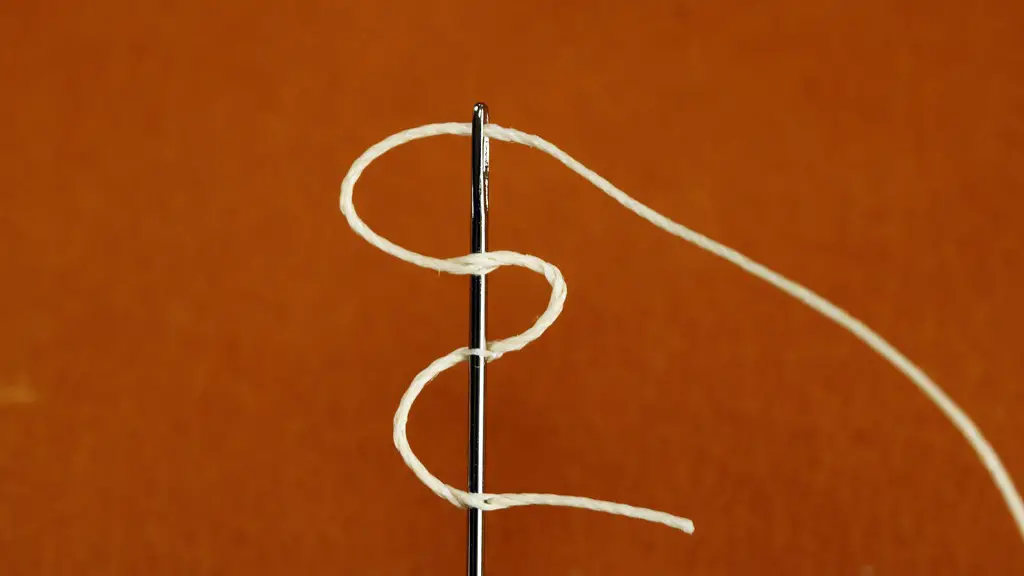

After the new tension assembly is installed and the allen wrench has been tightened, it is important to test it to see if it is working properly. Before actually sewing, there are a few simple tests you can do. Turn the hand wheel and make sure that the needle is properly aligned and does not indicate any kind of bind or snag on the fabric. If the needle makes a jerking motion, it is likely because the tension assembly is not assembled correctly.

Caring for the New Tension Assembly

Once the new tension assembly is installed and working properly, you should take the time to properly maintain the assembly. Often, this means lubricating the assembly with a light lubricant before each use. This helps to ensure that the tension assembly does not become stuck or malfunction over time. It is also important to inspect the tension assembly periodically to make sure that all of the bolts are tight and secure.

Troubleshooting Common Issues

It is also beneficial to understand how to troubleshoot any common issues with the tension assembly on the sewing machine. One of the most common issues is the fabric slipping when the machine is stitching. If this happens, it usually means that the tension assembly is too loose. To fix this, it is important to make sure that the allen wrench is tightened correctly and that the tension assembly is properly lubricated.

Best Practices When Installing a New Tension Assembly

In order to make sure that the tension assembly on the sewing machine is working properly and efficiently, it is important to follow the best practices for installation. Make sure to use the right tools for the job, such as the right-sized allen wrench and Phillips-head screwdriver. Also, make sure to lubricate the tension assembly before each use and inspect it periodically to make sure that it is working properly.

Consequences of Not Replacing an Old Tension Assembly

If an old tension assembly is not replaced, it can lead to numerous sewing issues. One of the most common issues is the fabric slipping while the machine is stitching. This can make it almost impossible to sew properly. Another issue is that the tension assembly may become too loose or too tight, resulting in poor stitching or broken needles. Additionally, an old tension assembly can cause the needle plate to become misaligned, resulting in stitches that are not even or that skip stitches.

Cleaning the Tension Assembly

Cleaning the tension assembly is also important. If the assembly is not properly cleaned and maintained, it can result in tension problems and other sewing difficulties. The first step to cleaning the tension assembly is to remove any debris or lint that may have accumulated. Use a small brush or damp cloth to do this. You can also use a mild soap and water solution to clean the assembly if necessary.

Tips for Keeping the Tension Assembly Working Properly

It is also important to keep the tension assembly of the sewing machine working properly. Proper maintenance and cleaning are key to this. Make sure to lubricate the tension assembly before each use and inspect it periodically. Additionally, it is important to make sure that the tension assembly is not too loose or too tight. This can result in poor stitching or broken needles. Lastly, if the tension assembly does become too loose or tight, replace it as soon as possible.