Skilled Preparation

Having the right items, equipment, and materials is key to a successful bobbin-replacement job on a Brother sewing machine. Here are a few items to gather before starting:

- A medium-sized phillips screwdriver

- A bottle of electric machine oil

- A dust cloth

- A set of spare bobbins

It is also important to know exactly what kind of sewing machine you have. A Brother sewing machine specific to a certain model might have different instructions for replacing the bobbin. Additionally, become familiar with the machine’s feed dog, pressure foot, stitch width, and stitch length. All these elements will provide a better background on the process of replacing the bobbin.

The Preparation Process

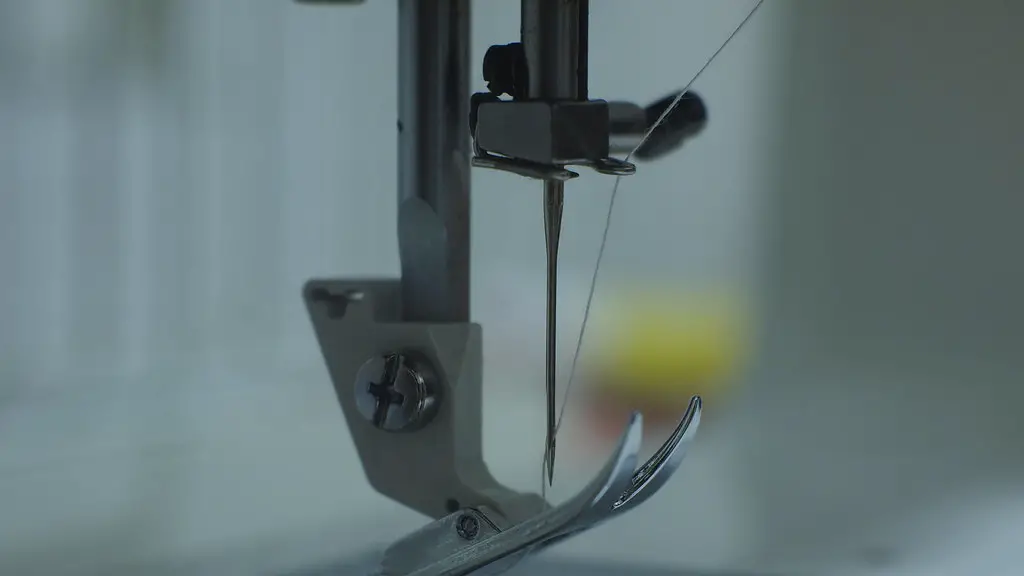

Before beginning the bobbin-replacement process, it is imperative to orient one’s self with the parts of the machine, so that accuracy and safety are ensured. A few safety measures: turn off the power, unplug the machine, and make sure the needle guard is closed. The areas of the machine may vary depending on the model, but here are the steps that are generally necessary to complete the job:

- Raise the presser foot, open the bobbin case, and remove the empty bobbin.

- Clean the bobbin case with a lint-free cloth and oil the bobbin race.

- Insert the new bobbin, making sure the thread is caught on the bobbin finger.

- Lift the spool pin, take the thread to the back of the machine, and wrap the thread tightly around the bobbin a few times.

- Pass the thread from the left to the right side of the machine and turn the handwheel counterclockwise.

- Retrace the thread to the groove on the bobbin. Push the bobbin case into the shuttle race.

In the case of inserting the thread into the bobbin, it is important to make sure the thread is tucked into the threading channel. It is just as important to align the thread as best as possible, so the bobbin will turn correctly.

Know the Steps

The most important elements in replacing the bobbin on a Brother sewing machine is the correct order; missed steps can cause tension issues that can lead to loose threads and limited stitch patterns.

- Set the bobbin onto the spool pin.

- Prefeed the bobbin thread through the tension disk, and then pull the bobbin thread to the underside of the throat plate.

- Firmly hold the needle thread on top while pulling the bobbin thread up.

- Ensure that the new thread is looped over the tension system.

- Tie the two threads together at the needle plate.

- Put in the bobbin winder, raise the presser foot lifter and start the machine.

- Once the thread spool is empty, cut the thread and press the foot peda

It is important to remember that this process requires the new bobbin to be wound properly, the new thread to be trimmed and not too long, and the needle thread tension to be set correctly. All of these steps are essential to replacing the bobbin and making sure it works properly.

Practice Passion

When replacing the bobbin on a Brother sewing machine, practice and patience can go a long way. As skilled repair technicians will attest, practice will help one to become an expert in this art. It is entirely possible to replace the bobbin on a Brother sewing machine with precision and accuracy, as well as a dedicated passion for the task.

Passion for the job is almost as important as the correct technique. As with any craft or manual skill, it is important to keep trying and practice until the skill is perfected. While mistakes will be made along the way, they should not happen if enough practice is implemented.

Tools and Techniques

To ensure a great job and the perfect stitching, it is important to analyze the process and to select the right tools. For instance, using a machine oil specifically designed for sewing machines will help decrease friction. Additionally, lint must be avoided and cleaned out of the machine as necessary.

In terms of techniques, mastering the art of bobbin winding can also give a better idea of proper threads, tension, and much more. Knowing where and how to properly insert the threads can be the difference between an exquisite job and a mediocre one. It is also important to remember to keep the needle area clean and free of any dust.

Maintenance Procedures

Once the bobbin is correctly installed, it is important to maintain the machine over time to prevent any problems from arising. A few recommendations from repair experts include:

- Changing the needles on a regular basis.

- Lubricating the parts inside the sewing machine.

- Checking the machine periodically for any dust or lint accumulation.

- Making sure the right pressure foot and stitch width is used according to the material.

- Replacing any broken or worn out parts.

Additionally, if a problem arises outside of regular maintenance, take the machine to an authorized repair technician who can help diagnose and solve more complex issues.

Experience and Expertise

Replacing the bobbin on a Brother sewing machine demands experience, expertise, and precision. What might seem like a simple job can become a complicated endeavor if not done correctly. Knowing the right combination of tools and processes, as well as honing the technique and maintaining the machine, are all essential to a successful and efficient bobbin-replacement job.

Although it can take a bit of time and patience, mastering the art of bobbin-replacement is completely possible. With tireless practice and passion, it is possible to hone the skill and acquire the expertise to replace the bobbin with perfection.

Time and Patience

Time and patience are also key elements when attempting to replace the bobbin on a Brother sewing machine. The process of bobbin-replacement requires immense precision, both in assembling the proper tools and materials as well as in executing the steps in the correct order. Anything less than perfect can lead to tension problems and the unwanted unraveling of stitches.

Taking the time to double-check all the steps and having patience when it comes to practice is a great way to ensure a successful job. Preparing ahead of time and familiarizing oneself with the machine and its parts is also essential for eliminating any unexpected problems, as well as for avoiding costly repairs.

Machines and Mastery

Knowing exactly what machine one is working with is an essential factor in replacing the bobbin on a Brother sewing machine successfully. Different models may have vastly different steps and techniques, as each machine is specifically designed to a certain model.

Therefore, researching and observing the machine as much as possible is a great step to acquiring expert knowledge. Observing the parts and pieces of the machine gives a better idea of how the bobbin can be replaced with precision and accuracy. If ever in doubt, referring to the owner’s manual is a great way to get back on track.

Succeeding on the First Try

Successfully replacing the bobbin on a Brother sewing machine the first time around can be an incredibly rewarding experience. However, it might take some determination and practice to master the art.

For instance, professionally managing the tension on the bobbin is a critical move that ensures that the bobbin is being wound or inserted correctly. The same goes for the foot pedal pressure, as it can also have a major impact on the bobbin-replacement job.

Follow Proper Directions

An accurate job is contingent upon a correct understanding and execution of the steps. Read the owner’s manual thoroughly to become familiar with all the necessary pieces. Additionally, it is always a good idea to double-check any loose ends before attempting the job itself.

Keeping the manual handy is also a great way to refer to it when any last-minute doubts arise. Operational videos and photographs can also help to break down the most difficult steps into a simpler format.

Make the Most of Resources

Having access to certified repair technicians, as well as to the local sewing-machine shop, can provide a great background on the process of bobbin-replacement. Their expertise and advice can prove to be invaluable during the entire process.

Gathering information from the internet is also a great way to collect information about the Sewing machine itself, as well as about the process of bobbin-replacement. Manufacturer websites are a great resource for learning more about the machine’s specs and features.

Protection and Prevention

On a final note, it is important to take proper protective measures when replacing the bobbin on a Brother sewing machine. Safety goggles are vital in protecting the eyes from any pieces or particles that may fly out of the machine during the process. It is also critically important to not touch any of the internal parts; doing so can cause permanent damage to the machine.

In addition to safety measures, it is a good idea to keep spare bobbins and a few extra needles on hand. That way, any unexpected issues that may arise during the process of bobbin-replacement can be fixed quickly and easily.

Conclusion

In conclusion, replacing the bobbin on a Brother sewing machine is an incredibly precise and intricate process. However, with the right tools, materials, and preparation, it is entirely possible to replace it with great results.

Observing the parts of the machine and honing the practice skill over time can help to develop the skill completely. With time, patience, and practice, the art of bobbin-replacement can be perfected with accuracy and precision.