Identifying the Needles

Replacing the needle on a Kenmore sewing machine is an easy job once you have correctly identified the correct needle. If a needle is bent or worn out, or you are switching to a new type of fabric, then it should be replaced. Take a look at the needle slot first to see which type of needle fits your Kenmore machine. Of course, it is also essential that the needle style matches the needle system size of the machine. If unsure, consult the user manual or contact a qualified service technician to assist in identifying the correct needle.

Preparing the Machine

Before replacing the needle, the power should be disconnected from the Kenmore sewing machine. The bobbin should also be removed from the machine and placed into its case for fact storage. Additionally, the bobbin should be assessed to make sure it is in good condition and does not need replacing too. Once these steps have been carried out, then it should be safe to proceed with replacing the needle.

Removing the Old Needle

finding the correct needle to fit the machine is only half the job; the needle must also be removed from the machine. The needle should be loosened by turning the hand wheel away from you. To adjust the needle clamp screw with a screwdriver this will release the needle. Pull the needle upwards and out of the machine. Be sure to dispose of the old needle carefully, as the sharp point can be dangerous.

Fitting the New Needle

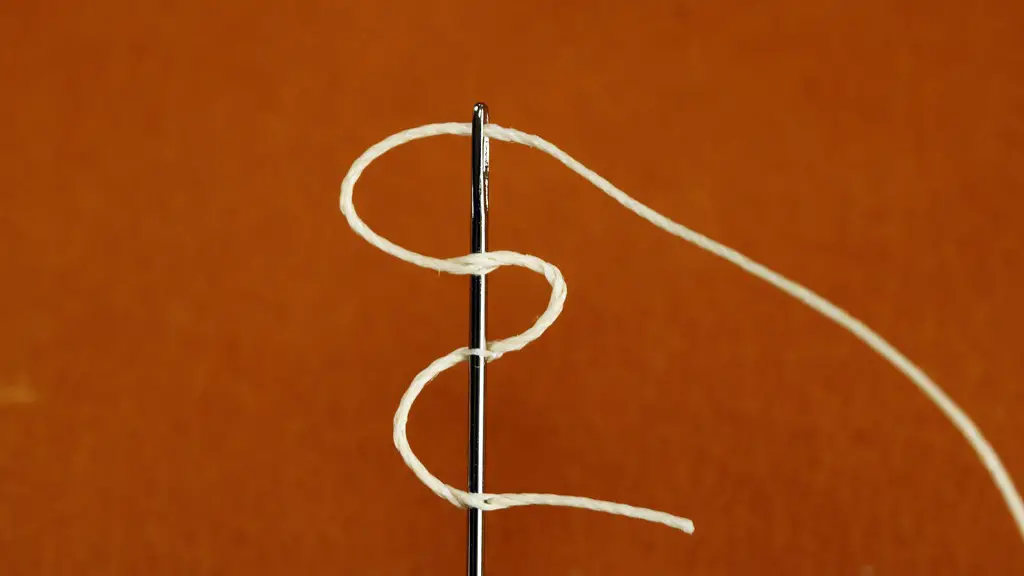

Now it’s time to fit the new needle. Take the new needle by the shank and release the clamping lever. Insert the new needle with the flat side of the shank facing towards the back of the machine. Up until now the needle should not have been tightened up, but now the needle clamp screw should be tightened by using the screwdriver.

Check Needle Height and Thread Tension

Once the new needle has been inserted and secured, turn the hand wheel to make sure it runs freely. Also check to see if the needle is indeed at the correct level – it should be perpendicular to the shuttle hook point. Then check that the thread tension is correct as well.

Start Sewing Again

The Kenmore sewing machine is now ready to use again once the needle has been replaced. Be sure to check the thread and tension prior to running the machine, as this could impact the final product. Keep a good supply of needles to hand so that you can replace them quickly and with ease.

Are there any Risks?

When replacing the needle, it is important to remember safety and respect for the machine. Needles can be dangerous if not treated properly, so take care when removing and replacing them. Additionally, if the needle is inserted incorrectly, it could cause damage to the machine and affect the quality of the stitch.

Maintaining the Kenmore Sewing Machine

The Kenmore sewing machine should be maintained to ensure it remains in good working condition, even when replacing the needle. Cleaning and oiling are key elements to help it run with optimal performance. Regularly check the bobbin too, as this can become worn out with use. A needle should be changed approximately every 10 hours of use, or more often with certain fabrics.

Different Types of Needle

When replacing a needle, choose the right type of needle and insert it in the correct direction. It should fit snugly and be held firmly in the needle slot. The type of needle will depend on the fabric to be stitched, so select from universal needles, ballpoint needles, stretch needles, denim needles or leather needles, depending on the task.

Check for Clearance

The clearance should be checked for the presser foot after changing the needle. This can be done by manually turning the hand wheel a few times – the foot should move up and down without hitting the needle. If the foot does not have enough clearance, then the needle may be too long or the needle clamp may need adjusting.

Troubleshooting the Problem

If the Kenmore sewing machine is not running as expected, it could indicate a problem with the needle or the needle insertion. Check the needle type, the tension and the needle height. The presser foot may also be too tight, and the bobbin may need checked to see if it has become jammed. If the problem persists, then contact a qualified service technician to assist in resolving the issue.

Using the Correct Shanks

When replacing a needle, another key point is to remember to post the correct type of shank. Again this should be checked against the machine model and needle system size. Universal or flat-shanked needles should be used for home sewing machines, as this will provide a tight fit in the needle slot when correctly inserted.

Frequently Changing the Needle

Needles should be changed regularly to ensure optimal performance and neat, professional stitching results. This is especially true when sewing delicate fabrics, as the needle can become bent or damaged over time. Furthermore, a new needle will give a sharper, more accurate needle point to prevent skipped stitches.

The Benefits of a Professional technician

Finding and fitting the right needle for a Kenmore sewing machine must be done accurately in order to maintain the performance of the machine and to avoid damage. As such, it is best to contact a qualified service technician who will be familiar with the product and its technical aspects. This will ensure a good fit that optimizes the overall stitch quality.