There are a few things you need to know in order to set your sewing machine needle correctly. First, you need to know what size needle to use for the type of fabric you’re working with. Second, you need to know how to insert the needle into the machine. And third, you need to know how to properly set the tension on the needle.

There is a small screw on the side of the sewing machine that loosens or tightens the needle. To set the sewing machine needle, first loosen the screw and then slide the needle into the slot at the front of the machine. After the needle is in place, tighten the screw until it is snug.

What is the first step in setting the needle in the sewing machine?

The machines I’ve used have the same steps for inserting/changing the needle:

1. Turn off the machine

2. Lower the presser foot

3. Raise the needle to the highest position by turning the handwheel (also called the flywheel) toward you

4. If the needle is in the machine, hold it while you loosen the screw that holds it in place

Most domestic sewing machine needles have a rounded front face and a flat back. This allows the needle to more easily penetrate the fabric and produce a more even stitch.

How do you adjust the needle on a sewing machine

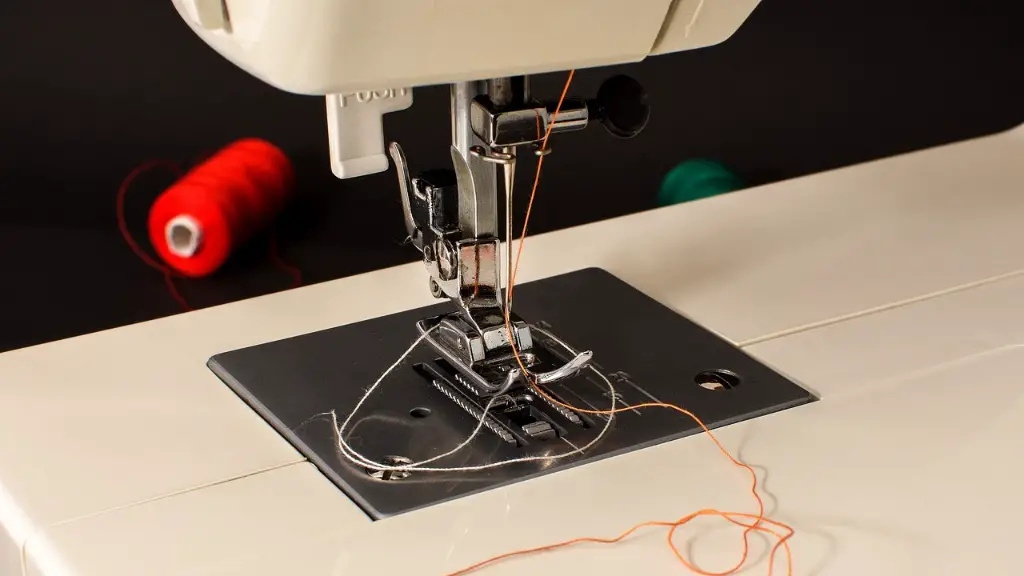

This is your needle board. So right over here that screw you see there, each machine have it. This is what you use to change your needle. You unscrew it, put your needle in there, and then screw it back in. And that’s how you change your needle.

Before you begin sewing on your machine, it is important to make sure that your needle is inserted correctly and that your needle clamp thumb screw is tightened securely. Therefore, insert your needle into the shaft with the flat side facing left, making sure the needle is all the way up into the shaft. Then, tighten your needle clamp thumb screw securely. Finally, before you begin sewing, make sure to slowly turn the handwheel of your machine towards you by hand to make sure everything is in working order.

Should the needle be up or down when you start sewing?

Before you thread the needle, it needs to be in its upmost position. If you need to, turn the hand wheel towards you to bring the needle up manually into this position. Now insert the thread into the needle, from front to back.

When you’re ready to shoot, make sure your arms are straight, with a slight bend at the elbows. This will help you maintain control of the bow and arrow and ensure a more accurate shot.

How do you tell if your needle is worn out?

If the grooves of your vinyl record look wider and deeper than those of other records in your collection, it is likely that the record has been played to death. If the grooves look good but the sound is still thin or tinny, then it is time to replace the needle.

If you are unsure if your sewing machine needle is bent, a quick way to check is to remove it and place it on a flat surface. With the needle’s shank flat side facing down, you can see if the needle is rocking back and forth or if it is laying perfectly flat. This will give you a good indication of whether or not the needle is bent and needs to be replaced.

Which needle determines stitch size

The size of a needle is described first by its diameter and secondly by its length. The size of the new stitch is determined in large part by the diameter of the knitting needle used to form it, because that affects the length of the yarn-loop drawn through the previous stitch.

The size of the needle has an impact on the position of the needle in the throat plate. A smaller needle will sit on the left side of the hole, while a larger needle will be more centered. There is no adjustment on the Featherweight for the position of the needle.

Why is my needle hitting the needle plate?

If the needle is hitting the needle plate while you’re sewing, it could be because you have the wrong needle plate on the machine. Make sure that the needle plate is the correct one for the stitch you’re trying to sew. If it is, and the problem persists, you’ll need to take the machine to the dealer to have it fixed, as something is out of alignment.

If you’re having trouble with your sewing machine needle, first check to see if the needle is installed correctly. The flat spot on the needle should face the back of the machine. If the needle is installed correctly and you’re still having trouble, the next thing to check is the needle clamp screw. Make sure that the screw is tight and not loose.

What angle the needle should be

Needle insertion:

Insert needle at a 90o angle to the skin with a quick thrust. Retain pressure on skin around injection site with thumb and index finger while needle is inserted. Aspiration is not necessary.

When giving a shot, it is important to hold the syringe at a 90-degree angle to the skin and to quickly jab the needle all the way in. This will help ensure that the needle is inserted correctly and that the medication is injected properly.

How far should the needle stick out?

If you’re tattooing with a needle, you’ll want to make sure the needle is sticking out far enough to dip into the pigment, but not so far that the pigment doesn’t have a chance to get on the needle. You’ll have to experiment to see what works best for you, but a good rule of thumb is to make the needle stick out about the width of the needle bar.

be sure to use the proper size of needle and thread for your fabric. Use the thread cutter to cut thread tails or trim threads with scissors as you work. The take up lever should always be at the “top” when beginning and ending a line of sewing.

Final Words

First, you need to know what type of needle your machine uses. Newer machines usually take universal needles, but older ones may require specific types. Once you have the correct type of needle, follow these steps:

-Thread the needle and pull the thread through the eye so that there is a long tail.

-Place the needle into the needle holder, making sure that the flat side of the needle is facing the back.

-Tighten the needle by turning the screw at the top of the needle holder clockwise.

-Pull the thread through the tension discs.

-Draw the thread up through the take-up lever.

-Set the stitch length by turning the knob at the side of the machine.

-Start sewing!

The process of setting a sewing machine needle is not difficult, but there are a few things that you need to keep in mind. First, make sure that the needle is the correct size for the fabric that you are using. Second, be sure to correctly insert the needle into the sewing machine. Third, be careful when tighten the needle, as you don’t want to break it. Finally, check the tension of the needle before you start sewing. Following these simple steps will ensure that you have a successful sewing experience.