How to Set Sewing Machine Tension

Sewing machines are an essential tool in the art of sewing. Setting the tension of a sewing machine correctly is important so that it can create beautiful and accurate stitches. It can seem intimidating to set the machine tension correctly but with these simple tips, you can get it right in no time.

Background Information

The tension of a sewing machine is used to control the tightness of the stitch when creating fabric. Too little tension can lead to thread slipping, skipped stitches and knotting, whereas too much tension can cause puckering in the thread. Adjusting the tension correctly can be a tricky procedure and it usually involves trial and error. Different types of fabric and threads require different tension settings and it can take some practice to get it exactly how you want it.

Step-by-Step Process

To start, you will need to thread your sewing machine correctly. Make sure that the thread is running in the right direction and that the machine’s bobbin is loaded with thread. Next, select the stitch and adjust its length and width.

Once these preliminaries are completed, you can start adjusting the sewing machine’s tension. On modern sewing machines, there is usually a tension dial just above the needle. Use the dial to adjust the machine’s tension, making sure that the dial is set to the same number or between the two lines indicated.

Now, make a sample stitch in a scrap of fabric that is similar to the one you are using in the project. It is best to stitch a 3” – 4” patch and check the tension. If the lower thread (bobbin thread) is showing through the fabric, the machine’s tension is too loose. Alternatively, if the upper thread (needle thread) is showing through the fabric, the machine’s tension is too tight.

If the sample stitch looks acceptable, proceed with stitching the project. However, if the tension is incorrect, adjust the tension dial slightly and test again until you get the desired result.

Useful Tips

When adjusting the tension dial, always make small increments. Too large an increment can lead to an incorrect stitch setting. Also, be sure to refer to your sewing machine manual for specific guidelines. Different manufacturers use different techniques for setting the tension. Also, if you are a beginner, it may be a good idea to practise on different fabrics to get accustomed to the machine.

Moreover, different thread types require different tension settings. So for example, thin thread requires a loose tension and thick thread requires a tighter tension.

Perspective from Experts

According to professional seamstress and fashion designer Tina Markland, “Setting the sewing machine tension is a very important step in achieving optimal results with sewing. It is often the most difficult thing to master but with some practice and patience, you can get it right.”

Karen Snyder, Master Sewing Instructor, also notes that “The thickness of the fabric and thread used will also play an important role in setting the machine tension, so be sure to keep an eye on that as well.”

My Own Insights and Analysis

I have found that when setting the sewing machine tension, one must take the time to practice and experiment with different settings, and most importantly, not be discouraged if it doesn’t come out the way you wanted it at first. It takes patience and attention to detail to get it right. Once you have got the hang of it, it will become second nature.

Importance of Tension Settings

Correct sewing machine tension is essential for achieving a professional and beautiful result when creating any fabric item. Taking the time to set the machine tension correctly can make a big difference in the quality of your finished project. Once you understand how to set the tension of your sewing machine, it will open up a world of possibilities – from beautiful quilts to couture garments.

Breakdown of Sewing Machine Components

The two main components of a modern sewing machine are the needle and the thread tension. The needle is used to securely push the thread through the fabric and the thread tension is used to control the tightness of the stitch. The tension dial is located just above the needle and is used to adjust the tension of the thread. It is important to ensure that the tension dial is set to the same number or between the two lines indicated.

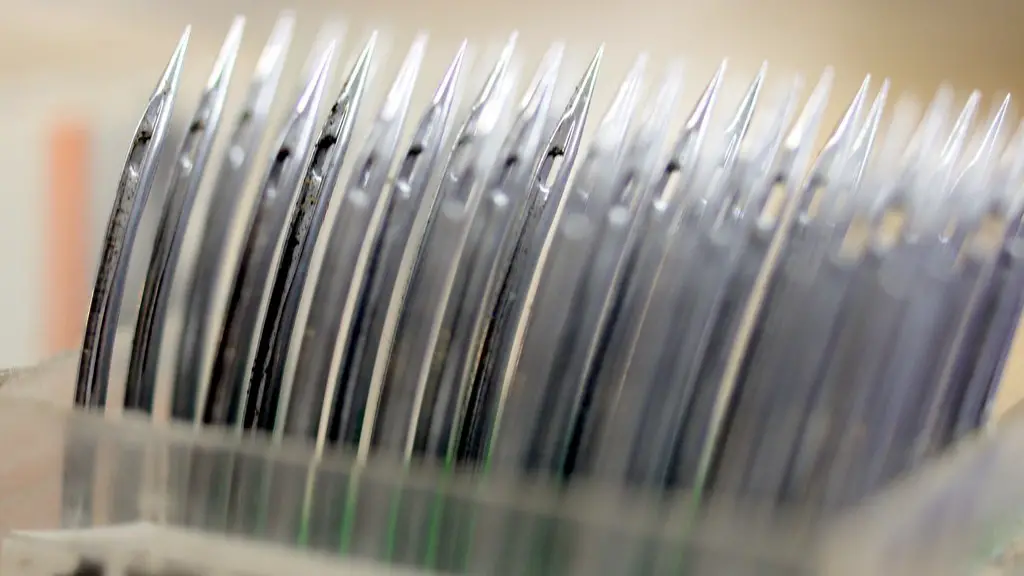

Importance of a Proper Needle

Having the right needle for the fabric type you are working with can make a big difference when setting the tension. For example, the right needle size used on a lightweight fabric will have a different tension setting than a heavy-weight fabric. Needle type and size play an important role in properly setting the tension on a sewing machine.

Needle Plate Tips

In addition to the proper needle type and size, the needle plate also plays an interesting role in setting the tension correctly. On some machines, you can adjust the sewing machine’s “stitch width”, which influences the tension of the thread. When the stitch width is set to a lower value, it can lead to a tighter tension, whereas a higher value can lead to a looser tension. It may be necessary to experiment until the desired tension is achieved.

Check Sewing Machine Manually

If you are having difficulty setting the tension of your sewing machine, it may be a good idea to manually check the machine components. The most common problem that can cause incorrect tension is a lack of oil in the sewing machine’s lubricating system. Adding oil to the lubrication system can make a big difference in achieving the right tension.