Identifying the Type of Tension Disk

Passing through the layer of fabric with a stitching needle starts with setting the tension. Learning how to set the tension on a Brother sewing machine accurately is critical to the success of your project. The right tension level will create a stitch that is evenly formed and firmly secured in the fabric.

The tension setting will depend on the type of fabric and thread used in the project. Different fabric and thread combinations will require different tension levels. If the tension is set too low, the stitch could unravel. Too tight tension could make the fabric puckers. The initial step to setting the tension is identifying the type of tension disk on your sewing machine.

Older Model Tension Disks

Many of the older Brother sewing machines use the older model tension disks. They usually have a dial on the front of the machine at the top. This type of tension disk must be adjusted manually by turning the dial. The dial has numbers on it. The higher the number, the higher the tension. A few of the older Brother machines use two dials. These machines require separate tension adjustments for the upper and lower tension settings.

Newer Model Tension Disks

Many of the newer Brother sewing machines are equipped with a tension disk of a newer design. The newer model tension disks allow you to use a button to set the tension. This type of tension disk is also commonly referred to as an automatic tension disk since it can be adjusted with the push of a button. It works by adjusting the tension according to the type and thickness of the fabric that is being used.

Threading the Machine and Thread Tension

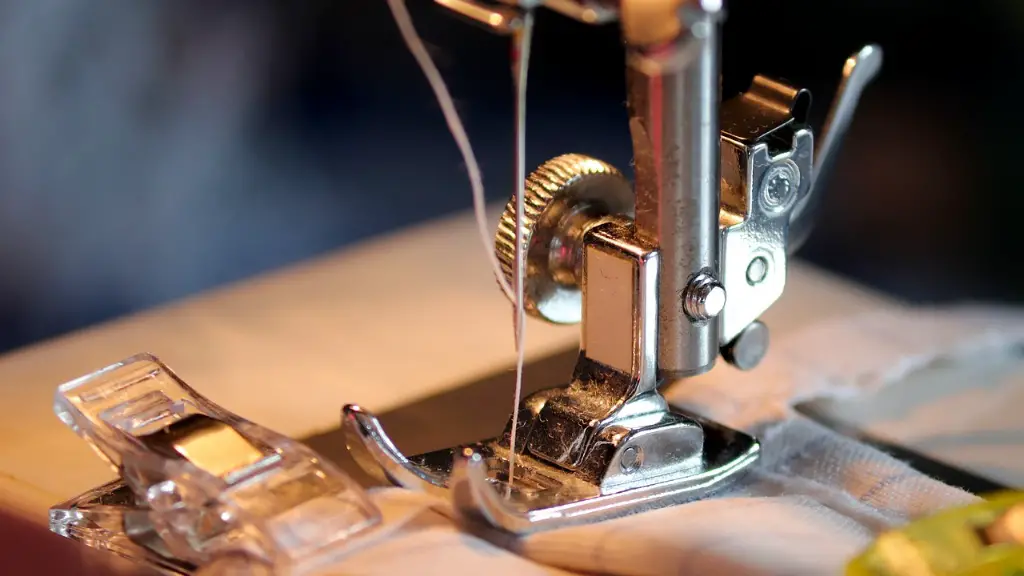

Once the type of tension disk has been identified, you need to thread the machine. Properly thread the machine with the stitching needle and thread. Make sure to thread the machine according to manufacturer instructions. Once the machine is properly threaded, you can begin adjusting the tension for the thread.

For thinner threads, you will use a lower tension. Thicker threads require a higher tension setting. After the machine has been threaded and the type of fabric that you will be sewing has been identified, set the tension to the mid-range. Take advantage of the stitch sample feature on the automatic tension disk to fine-tune the tension to the style of stitch desired and the right segment of the dial.

Checking the Tension

Once the tension is set, you need to check the tension to make sure that it is set correctly for the fabric and thread selected. To check the tension, the bobbin needs to be in place and the machine needs to be threaded. Place a piece of scrap fabric inside the machine. Then lower the stitching needle into the fabric and slowly start sewing.

As the sewing machine begins to stitch, carefully monitor the underside of the fabric. The stitches need to be even. If the stitches are loopy, the tension is too loose. If the fabric gets pulled too tightly, the tension is too tight. Readjust the tension as needed, until the stitches are evenly formed.

Length of Stitch Adjustment

Stitch length is also important. Setting the stitch length affects both the look and durability of the stitch. Stitch length is measured in millimeters and is often designated on the stitch selector plate as “L,” which stands for length. To adjust the stitch length, use the stitch selector controls supplied with the newer model machines. The stitch length can also be manually adjusted by adjusting the speed of the machine.

Making Necessary Adjustments for Special Fabrics

The tension disk needs to be adjusted when special fabrics such as sequins, velvet, or a tulle fabric are being sewn. These fabrics have their own special tension requirements. These fabrics require more tension and may need to be manually adjusted for the best stitching results.

Frequently Checking the Tension Disk

Machines should also be checked frequently for dirt buildup in the tension disk area. Clean out the lint and dirt with canned air. The canned air will also help get rid of buildup on the spoon-shaped tension disk. It is also important to make sure that the tension control dial is properly tightened.

If you are still having trouble getting the tension right, consult the Brother sewing machine manual or contact Brother Customer support.

Testing the Right Tension

Once the machine is properly threaded and the tension is set, test the tension on a scrap piece of fabric. Turn the hand wheel towards you until the needle is in its lowest position. Raise the presser foot lever, and raise the needle to its highest point. Pull the thread from the fabric. The thread should remain in the position without slipping.

Picking the Best Thread

It is also important to choose the correct thread. The thread needs to match the fabric both in color and weight. Different types of fabric may require different types of threads for tension. A good rule of thumb is to choose a thread that is twice as fine as the fabric used. This will allow the fabric and thread to move fluidly with the tension settings.

Choosing the Right Needle

The needle is an important factor when it comes to setting the tension. It is important to choose the right needle. The needle size needs to match the weight and texture of the fabric. In general, thicker fabrics need thicker needles and thinner fabrics need thinner needles. It is also important to make sure that the needle is sharp and clean before use.

Testing Tension After Making Adjustments

Once the tension and needle is set, sew a few stitches on the scrap fabric. Take samples of the stitches on the sample piece of fabric. Examine the stitches carefully. They should be uniform and even. If the tension is too tight or too loose, adjust accordingly. Repeat the process until the stitches on the sample fabric look perfect.

Saving the Tension Settings for Use Later

Once the tension has been set and the stitches look good, save the settings for future use. If the same project needs to be done later, the tension settings can be recalled from the memory of the machine. This saves time and ensures that the tension settings remain consistent.