Attach the Thread Spool

The first step in setting the thread on your sewing machine is to attach the thread spool. Start by raising the needle to its highest position using the hand wheel. If the thread spool holder is not part of the machine, then you may need to set it up before attaching the spool. To do this, remove the top cover of the sewing machine and use a needle threader to gently pull the thread through the tension discs. Once the spool holder is secured, the spool of thread can be placed on the holder and secured in place.

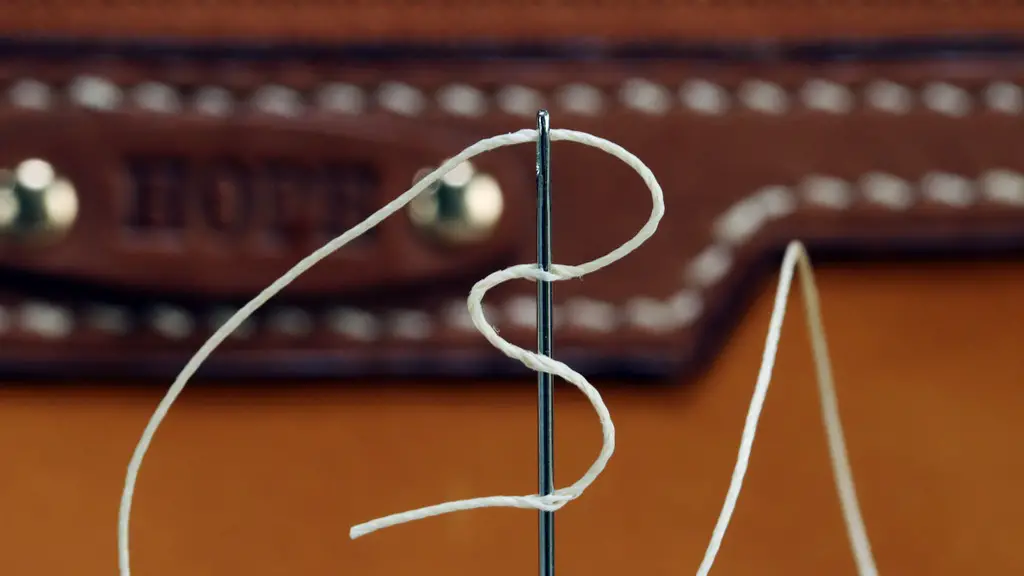

Thread the Needle

The next step is to thread the needle. To do this, you’ll need to thread the thread from the spool to the needle. Start by threading the end of the thread through the needle’s eye, making sure that the thread is not twisted or tangled. Then, hold the thread behind the needle, then pass it through the loop on the needle threader. Make sure that the thread doesn’t get twisted or tangled as it passes through the needle’s eye. Finally, make sure to leave enough thread on the spool when you’re done threading the needle.

Thread the Bobbin

Before you can use your sewing machine, you need to thread the bobbin. To do this, you need to remove the bobbin from the machine and thread the same type of thread through its eyelet. Start by passing the end of the thread through the bobbin’s eye. Then pull the end of the thread through the knot on the spool until the bobbin is securely tied. After this, you need to place the bobbin inside the machine, making sure that the thread is not twisted or tangled.

Guide the Thread

Once the bobbin is securely tied, you need to guide the thread through the guides and tension discs. Start by placing the needle threader into the guide and passing the thread through it. Make sure that the thread is not tangled or twisted as it is pulled through the guide. After this, pass the thread through the tension discs, making sure that the threads don’t get tangled or twisted as it passes through them.

Set the Tension

After the thread has been passed through the guides and tension discs, you need to set the tension of the thread. To do this, you need to use a tension screwdriver to adjust the tension on the thread. Start by turning the tension screwdriver clockwise to increase the tension, or counterclockwise to reduce the tension. Make sure to set the tension so that it’s just right for the type of fabric and thread you’re using.

Test the Stitches

Once the thread has been secured and tension has been adjusted, it’s time to test the stitches of your machine. To do this, you need to select a piece of fabric to test the stitches on and start sewing. As you sew, make sure to pay attention to the stitch pattern and tension. If the stitches are too tight or too loose, then you need to adjust the tension again.

Pull on the Threads

Finally, to ensure that the thread has been set properly, you need to pull on the threads. Start by pulling gently on the thread that’s connected to the needle. If the thread is too loose, then the stitches may come loose and if the thread is too tight, it may break. Once you’ve tested the thread tension, you’re all set to start sewing.

Further Information and Processes

Oiling the Machine and Changing the Needles

To ensure that the sewing machine is running smoothly, it’s important to oil it regularly. To do this, you need to use a needle threader to lift the shuttle cap off the bobbin case and then use a few drops of oil to lubricate the moving parts of the machine. Additionally, it’s also important to change the needle regularly as it may dull over time. To change the needle, you need to first remove the old needle and then insert the new one.

Threading the Bobbin Case

Once the needle is changed, you need to thread the bobbin case. To do this, start by opening the shuttle door and then placing the bobbin in the bobbin case. Once the bobbin is in the bobbin case, you need to thread the bobbin case and the needle. Start by passing the thread looped around the shuttle hook and then through the tension spring. Once the thread has been pulled through the thread guide, you’re ready to start sewing.

Removing and Cleaning the Bobbin Case

It’s important to regularly remove and clean the bobbin case to ensure that the thread tension isn’t too tight or too loose. To do this, start by unscrewing the bobbin case from the shuttle and then carefully remove the thread from the bobbin case. Once the thread has been removed, hold the bobbin case under running water to remove dirt and debris. Once the bobbin case is clean, re-assemble it and thread it again.

Checking the Thread Tension

Regularly checking the thread tension is essential to ensure that the stitches are even and secure. To check the thread tension, start by selecting a knit fabric and adjusting the tension accordingly. Then run a few stitches and take a look at the stitches. If the stitches are too tight or too loose, then adjust the tension again.

Switching the Stitch Length and Width

Finally, you can choose to adjust the stitch length and width of your sewing machine. To do this, use the width and length dials on the front of the machine. By adjusting these dials, you can customize the stitch pattern to suit your needs. Additionally, you can also adjust the speed of the machine by using the speed control dial.