Parts of a Singer Sewing Machine – Recognize & Identify Them

Singer sewing machines are a popular choice for home and commercial use alike. When looking to thread an older Singer sewing machine, knowing what each part is and does is essential. The table, bobbin winder, needle and thread guide arm, sewing thread spindle, and needle plate are all important components to recognize.

The table on a Singer sewing machine is the flat surface that the fabric is placed on. It allows the fabric to remain stationary while the bobbin winds and needle moves up and down.

The bobbin winder is an arm that is placed in the table with a separate spindle. This spindle is used to wind thread onto the bobbin as the machine is running.

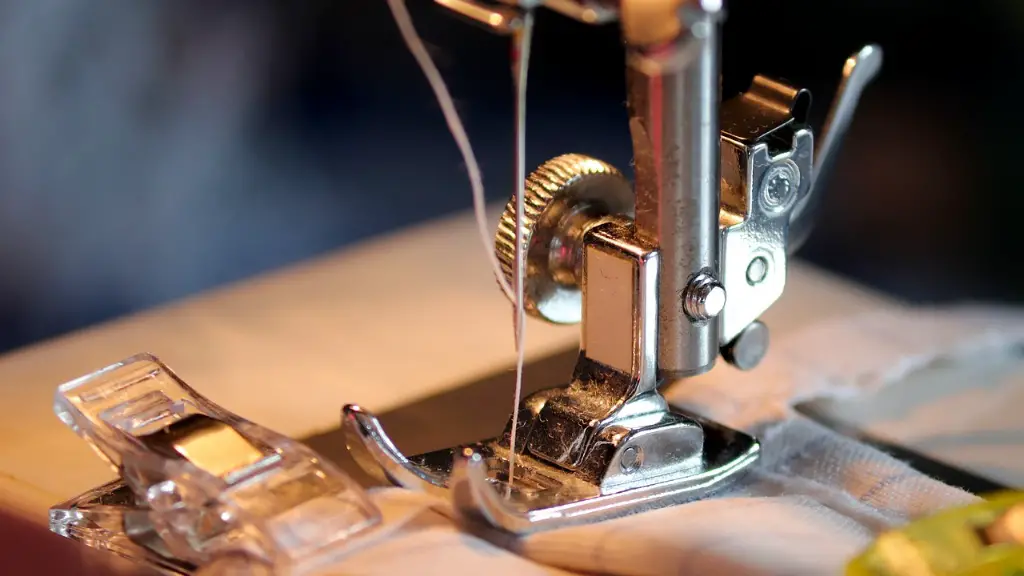

The needle and thread guide arm is a metal arm that moves up and down with a long lever. This arm holds the needle in place while the machine is operating and is used to guide the thread through the eye of the needle.

The sewing thread spindle is a metal cylinder that attaches to the needle and thread guide arm. The spindle is responsible for feeding the thread through the eye of the needle and securing it in place as the machine runs.

Finally, the needle plate is a flat plate that sits beneath the needle. It is used to help secure the needle in place and ensure the thread is properly fed through the eye of the needle.

Threading the Bobbin

The first step in threading an older Singer sewing machine is to thread the bobbin. To do this, begin by inserting the bobbin into the bobbin winder spindle and winding it counter-clockwise to wind the thread. Once the bobbin is full, slide it off the spindle and lay it on the table.

Next, take the thread and insert it into the thread guide arm so that the thread goes through the eye of the needle. Pull the thread towards the right side of the machine and then insert it into the thread spindle.

Once the thread is in the spindle, press the lever on the thread guide arm down. This will feed the thread through the eye of the needle and pull it away from the spindle.

Threading the Needle

The second step in threading an older Singer sewing machine is to thread the needle. Begin by taking the thread and inserting it into the eye of the needle.

Next, pull the thread towards the right side of the machine and insert it into the thread spindle. Once the thread is in the spindle, press the lever on the thread guide arm down.

Finally, take the thread and pull it around the needle plate and insert it into the eye of the needle. Once the thread is inserted, the needle should be completely threaded.

Securing the Thread onto the Spool

The third step in threading an older Singer sewing machine is to secure the thread onto the spool. To do this, begin by taking the thread and inserting it into the thread guide arm so that the thread goes through the eye of the needle.

Next, take the spool of thread and place it into the hole in the table. Once the spool is in place, take the thread and wrap it around the spool a few times and then feed the thread into the thread spindle.

Finally, press down the lever on the thread guide arm to feed the thread through the eye of the needle. This will secure the thread onto the spool and allow the machine to function properly.

Tension Adjustment

The last step in threading an old Singer sewing machine is to adjust the tension. Begin by turning the knob located on the side of the machine. This will allow you to adjust the tension on the thread as it passes through the eye of the needle.

Next, hold the thread in place and adjust the knob until the thread is in a tight position and does not move. This will ensure that the thread will not slip through the eye of the needle as the machine is running.

After the tension has been adjusted, the thread should be securely wound around the spool. This will ensure that the thread does not come apart as the machine is running.

Inserting the Needle into the Arm

An important step in threading an old Singer sewing machine is to insert the needle into the arm. To do this, begin by unscrewing the metal arm located at the top of the table. This arm is used to hold the needle in place while the machine is running.

Next, take the needle and insert it into the metal arm. The needle should be inserted so that the needle is facing downwards and the eye of the needle is pointing towards the right side of the machine. Once the needle is in place, screw the metal arm back on.

Finally, position the arm so that the needle is close to the fabric. This will ensure that the needle will be able to penetrate the fabric without getting stuck.

Starting the Machine

The final step in threading an older Singer sewing machine is to start the machine. To do this, begin by pressing down the foot pedal located at the base of the machine. This will cause the needle to move up and down, and the machine will begin sewing.

Once the machine is running, adjust the mixer knob located at the top of the machine. This knob is used to control the speed of the machine. Be sure to monitor the speed of the machine as it will be necessary to adjust the speed depending on the fabric being used.

Once the speed is adjusted, the machine should be ready to start sewing. Be sure to check that the fabric is properly secured and that the needle is in the correct position before starting the machine.

Additional Tips & Warnings

When threading an older Singer sewing machine, always make sure the needle is in the correct position and the fabric is properly secured. If the needle is incorrectly positioned or the fabric is not securely held, the fabric may bunch up or the machine may jam.

Additionally, always use the correct type of needle for the type of fabric being used. Different types of fabric require different types of needles. Using the wrong needle can cause the needle to break or not penetrate the fabric correctly.

Finally, it is important to use the correct thread for the type of fabric being used. Using the incorrect thread can cause the thread to break or not penetrate the fabric correctly. Always take the time to select the correct thread when threading an older Singer sewing machine.