How to Thread the Bottom of a Sewing Machine

Sewing machines have been used for decades to make clothing, accessories, and home decor. Threading the bottom of a sewing machine is a necessary step to get it ready for any kind of sewing project. It’s important to properly set up and thread the machine, as it affects the accuracy and quality of stitches. Knowing how to thread the bottom of a sewing machine can save you time and effort when it comes to getting your projects done.

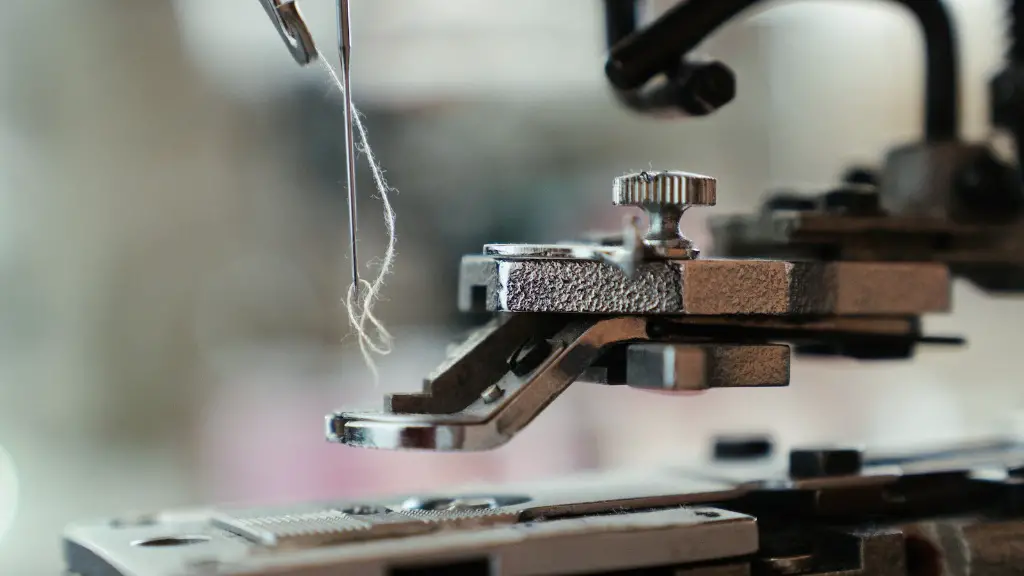

To start, locate the bobbin, which is a round piece of plastic or metal with a hole in the center, and the bobbin winder, which is a metal disk with a cog. First, you must fill the bobbin with your desired thread. Make sure to select a thread that is strong enough for the project you are working on. Once the thread is loaded, place the bobbin onto the bobbin winder and make sure it remains in place. Use the manual spool pin to hold the thread in place and then press the bobbin winder to rotate the bobbin and wind the thread onto it.

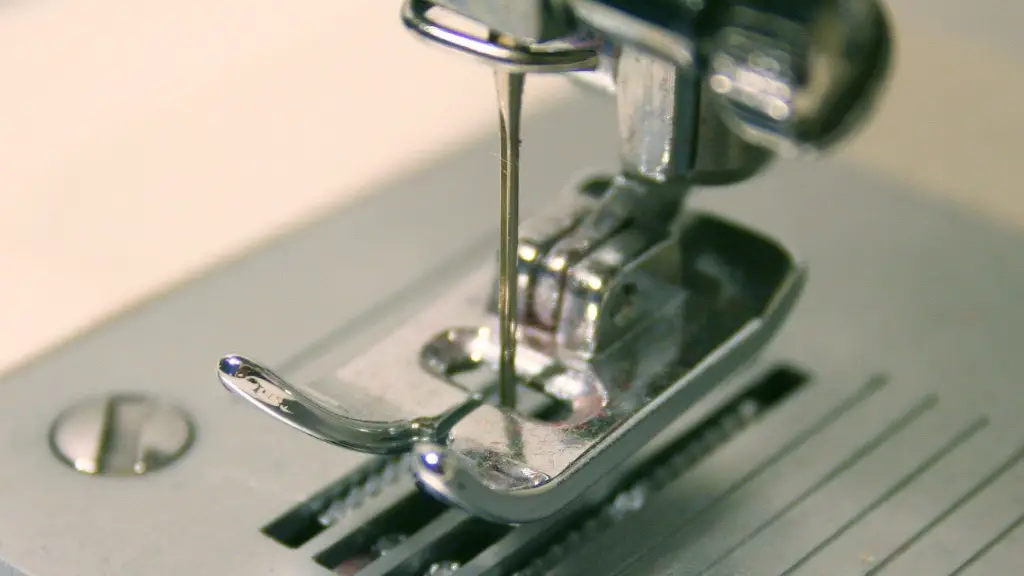

Next, use the manual shuttle hook in order to get the thread from the bobbin into the seam. The shuttle hook is a metal loop that sits between the needle and the bobbin. You must feed the thread through the shuttle hook so that the end of the thread is positioned correctly in order for the machine to stitch. Once the tread is correctly in position, you can secure it with a knot.

The final step is to bring the two threads together. First, pull the top thread up through the needle eye and then gently pull the bottom thread towards the top. This ensures that both threads are properly connected and will not be caught in the machine. You should always check the tension of the threads after you have threaded the machine. You must make sure that the top and bottom threads are neither too tight nor too loose.

Once the machine is properly threaded, you can start sewing your project. It’s important to remember to adjust the tension and the stitch size, depending on your project. You should also always keep the sewing area clean and free of lint, as it can get caught in the machine and interfere with stitching. Properly threading the bottom of a sewing machine can make all the difference in having successful projects.

Checking Your Threads

Testing the thread is an important step before you begin sewing your project. To test the thread, draw the thread around your fingers to check for any knots or tangles that could cause problems while sewing. Additionally, you can pull on the ends of thread gently to see if the threaded area is smooth and even. If the thread is too tight, it can cause the material to pucker or bunch, which is why it’s important to make sure the tension is correct.

The bobbin should also be tested. You can do this by taking out the bobbin and turning it over. Look for any kinks or tangles on the thread that may cause problems when you start to sew. You should also make sure all parts of the bobbin are working together properly. If the bobbin isn’t rotating smoothly, it can lead to problems while sewing.

Testing the thread also gives you the opportunity to make any necessary adjustments, such as adding more thread or adjusting the tension. This helps to ensure that your project won’t have any problems caused by incorrect threading. Taking the time to check your threads before starting a project can be the difference between success and failure.

Common Threading Mistakes

Threading a sewing machine can be complicated, and it’s easy to make mistakes. Common threading mistakes include not properly aligning the threads, not adjusting the tension and not checking for knots or tangles. Most of these mistakes can be avoided by following the instructions and taking the time to check for any errors. If you’re not sure about something, it may be best to seek out expert advice.

Another common mistake is not winding the bobbin properly. Make sure to use the manual spool pin and bobbin winder to attach and wind the thread correctly. Be sure to rotate the bobbin and wind the thread on until it is tight and even. If the bobbin doesn’t turn properly, it can both cause the thread to knot and prevent the needle from stitching correctly.

It’s also important to make sure the thread is not too loose or too tight. If the threads are too loose, the stitching will not be as strong and may cause the material to move as you sew. If the threads are too tight, the needle may break or cause the fabric to bunch up. Testing the thread before sewing can allow you to adjust the tension so that the stitching is strong, even, and will last.

Tips for Threading

Threading a sewing machine can be difficult, but there are some tips that can help make the process easier. To begin, lay out all the pieces and materials, such as scissors and thread, that you need before you start, as this will help save time. Make sure to keep the area clean, as lint can get into the machine and affect the quality of your sewing.

It’s also important to take your time when threading. Take slow and careful steps, as rushing can lead to mistakes. Patience is key, so don’t be afraid to take breaks or come back to it if you are having difficulty. You should also make sure to read the instructions or watch videos to get a better understanding of how to thread the machine.

Most importantly, make sure you are using a high-quality thread for your project. There are many types of thread available, such as cotton, polyester, and nylon, and each has different strengths and weaknesses. Choosing the right thread for your project is essential to achieving a successful outcome.

Changing the Spool of Thread

At some point, you may need to change the spool of thread in your sewing machine. When this happens, you should first take out the old spool of thread and replace it with a new one. Make sure to secure the new spool on to the manual spool pin firmly before beginning the threading process. Additionally, you should also ensure that the thread is wound correctly so that it does not knot or tangle.

If you’re using a top-loading bobbin, you should also empty the bobbin of the old thread and discard it before refilling the bobbin with the new thread. This helps to prevent any lint or dust from building up in the machine. Make sure to select the right type of thread for the project you are working on and use the manual shuttle hook to feed the new thread through the seam.

You should also use the manual clamp to hold the two pieces of thread together so that they do not move during stitching. Once the threads are in place, you can begin sewing. Changing the spool of thread can help keep your machine functioning properly and can make the process of stitching easier.

Threading the Needle

The last step to threading the sewing machine is to thread the needle. First, unthread the needle by pulling it up and off the unit. Once the needle is unthreaded, you can begin to thread it. You will need to select the correct type of needle for your project and make sure that it is securely in the needle bar. Place the thread in the needle eye and make sure the thread is not too tight or too loose.

Once the needle is threaded, you can begin to check to make sure that it is properly tensioned. To do this, pull the thread gently down towards the bobbin case and watch to see if the needle is either catching the tension spring on the back of the needle bar or being pushed away. If the needle is not being pushed away, the tension is too tight and you should loosen it.

It’s important to make sure the needle is correctly threaded and tensioned, as this affects the quality of the stitches and the strength of the fabric. If the needle is not correctly threaded and tensioned, the fabric can move as you sew and cause the stitches to be uneven and break apart.

Importance of Threading

Threading a sewing machine correctly is vital to successful sewing projects. Knowing how to correctly thread the machine can save you time and prevent problems from occurring while stitching. When threading the machine, it’s important to take your time and check for any mistakes, such as knots or tangles, that could cause problems. Additionally, make sure to examine the correct tension and the quality of the thread.

It’s also important to have the right tools for the job. Accessories such as scissors and measuring tape can help to get the job done quickly and efficiently. Additionally, it’s important to use the right kind of thread and needle for the project. Investing in quality materials and taking the time to thread the machine correctly will ensure that your projects are successful.

Knowing how to properly thread the bottom of a sewing machine is essential. Taking the time to understand the importance of threading and setting up your machine correctly can make all the difference in achieving the best results. From checking and adjusting the tension to winding the bobbin correctly, proper set up will ensure that your projects turn out looking professional and polished.