Explanation of Different Serger Sewing Machine Models

A serger sewing machine is an essential piece of equipment for anyone who regularly sews, whether they are a beginner or a professional. This type of machine is used to make the finished edges of the fabric look neat, by creating a neat stitching around seams or hems, which provides a strong and lasting stitch.

There are several different models of serger sewing machines on the market. Each model has its own features and differences in type, capabilities, and price, so it is important to do some research before choosing one. Some popular models include the Brother 1034D Serger, the Janome MyLock 654D, and the Singer Professional 5 Serger.

The Brother 1034D Serger is an entry level model that is great for beginners. It has 13 stitches and 50 stitches per minute (spm). It also has an adjustable stitch length and width, and a thread cutting system. It is a great choice for someone looking for an affordable serger sewing machine that has all of the basic features.

The Janome MyLock 654D is a great choice for more experienced sewers. It comes with 22 built-in stitches and has a maximum speed of 1300 spm. It also has an adjustable differential feed, a built-in needle threader, and an adjustable presser foot. This machine is perfect for someone looking for a machine that is reliable and can handle larger projects.

The Singer Professional 5 Serger is the perfect machine for professionals. It has a total of 32 built-in stitches and an adjustable stitch length, width, and speed. It also comes with an adjustable differential feed, a thread cutter, and a built-in needle threader. This machine is ideal for a professional who needs a reliable and durable machine that can handle any project.

How to Use a Serger Sewing Machine

Using a serger sewing machine is not as complicated as it may seem. The most important step is to make sure that you are familiar with the machine and its components. Before you start sewing, you should make sure that all of the parts are properly in place and that the machine is threaded correctly.

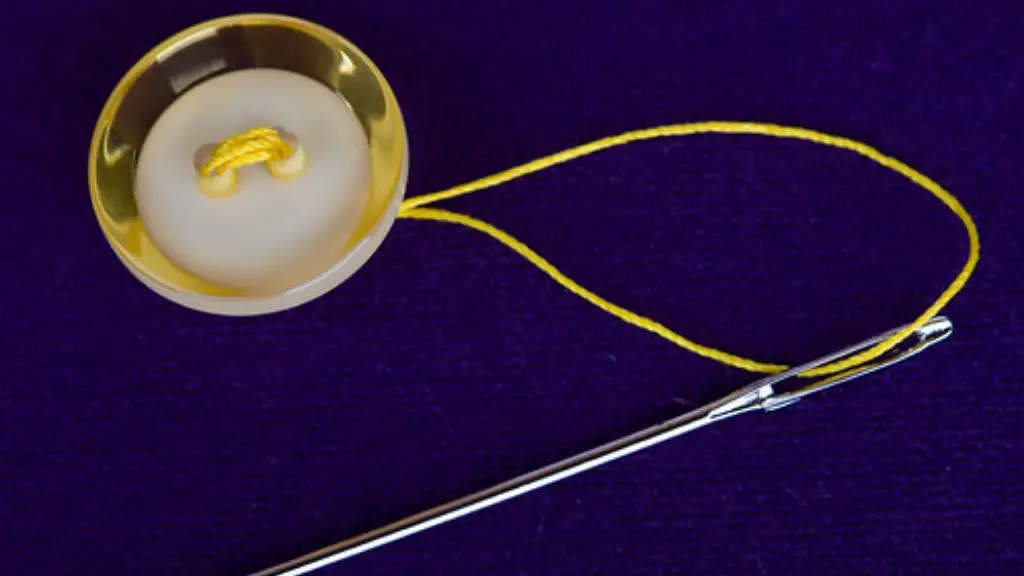

When threading the machine, you should first remove the thread spool from the machine by pushing the spool pin to the right. Next, thread the needle as indicated in the machine’s manual. After threading the needle, you will then thread the looper. This is done by feeding the thread through the thread guide and then wrapping it around the looper. Finally, the thread should be pulled through the tension discs, which are located on the back of the machine.

Once the machine is threaded and ready to use, you should start by adjusting the tension correctly. The tension can be adjusted by turning the dials located on the front of the machine. It is important to make sure that the tension is not too tight or too loose as this could affect the quality of the stitch.

When it is time to start sewing, you should pay attention to the foot pedal. This will control the speed of the machine. For more precise stitching, you should use a small, slow speed. You can then increase your speed as you become more familiar with the machine.

Finally, remember to unplug the machine when you are done using it. It is important to protect your investment and to keep the machine from overheating or becoming damaged. Once you own a serger sewing machine, it can be used for many sewing projects.

Types of Serger Stitches

One of the great things about owning a serger sewing machine is the variety of different stitching patterns that you can achieve. There are two main types of serger stitches – the overlock stitch and the cover stitch. The overlock stitch is used to finish the edges of the fabric and create a neat edge. This type of stitch is usually used on heavy fabrics such as denim or canvas.

The cover stitch is the second type of serger stitch and it is used to finish the hem of a garment. It creates a more professional finish than the overlock stitch. This type of stitch is usually used on lighter fabrics such as t-shirts and blouses.

When selecting a stitch, it is important to consider the fabric that you are working with. The thickness of the fabric and the desired effect will determine which stitch should be used. Additionally, some machines have specialty stitches that can be used for embroidering and appliqueing.

When selecting a stitch, remember to read the machine manual for instructions on how to properly set the machine up for the desired stitch. Depending on the type of stitch, you may need to use multiple threads when threading the machine, or change the tension settings.

Tips and Tricks For Serger Sewing

Once you have chosen the right serger sewing machine and familiarized yourself with its parts and components, you are ready to start creating. Here are some useful tips and tricks for serger sewing.

Before you begin, it is important to remember that the serger stitching needs to be finished before the fabric is cut. When working with a serger, it is important to adjust the width, length, and tension of the stitch as needed for each project. This will ensure that the stitch is neat and secure and will also ensure that the fabric does not stretch or pucker when stitched.

When cutting, it is best to use a rotary cutter to cut fabric. This will ensure that the fabric is cut correctly and uniformly. Also, it is best to use a cutting mat to avoid damaging your table. It is also important to remember to use the right type of needle for each fabric. Different types of needles will vary in size and thickness and should be used according to the fabric being used.

When threading the serger, it is best to start with the needles first and then thread the looper. This will ensure that the thread is secure and can be easily identified when sewing. To ensure that no loose thread remains after sewing, it is important to tie off any excess thread before cutting.

Finally, it is important to ensure that thread has been properly trimmed when you are finished sewing. If the thread is not trimmed, it could unravel and cause the stitch to become loose and potentially come undone. The best way to trim thread is with small scissors.

Maintenance of Serger Sewing Machines

Regular maintenance of a serger sewing machine is an important step in keeping the machine running properly and extending its lifespan. A few simple steps can help keep your serger sewing machine clean, running smoothly, and in good condition.

When cleaning a serger machine, it is important to use a soft cloth and lint-free cloth to wipe down the exterior of the machine and oil any parts that move. Additionally, it is important to periodically clean out the lint from the inside of the machine. Doing this will reduce the risk of the machine jamming or overheating.

It is also important to remember to oil the machine regularly. This can be done by applying a small amount of sewing machine oil to each of the moving parts. This will help to keep the machine running smoothly and prevent unnecessary wear and tear.

Finally, it is important to keep the needles and presser feet of your serger sewing machine in good condition. This can be done by swapping out the old parts for new parts regularly. This will ensure that the machine is running properly and that the stitches will appear to be neat and uniform.

Keeping Track of Serger Sewing Machine Accessories

When owning a serger sewing machine, it is important to keep track of all of the machine’s accessories. This includes any extra needles, threads, bobbins, presser feet, or other replacement parts. Keeping a record of which parts have been used and when will help you to keep your machine in good condition and track the life of the parts.

It is also important to keep track of the machine’s manual. This will help you should you ever need to troubleshoot the machine or make any adjustments. Additionally, it is important to remember to write down the serial number of your machine in case you ever need to make any warranty claims.

It is also a good idea to keep spare parts on hand in case the machine ever needs repairs. This will help to keep the machine running without having to wait for parts to be shipped or go to a repair shop. Spare parts can be purchased online or from your local sewing shop.

Finally, it is important to remember to have your machine serviced regularly. This can help to identify any potential problems or safety hazards before they become serious issues. A professional will be able to identify any potential issues and can provide advice for keeping your machine running smoothly.

Common Errors With Serger Sewing Machines

The most common errors with serger sewing machines are not properly threading the machines, incorrect tension settings, and clogged needles. When threading a machine, it is important to thread the needles first before threading the looper. Additionally, threading the machine incorrectly can cause poor stitches that may unravel and can even cause the machine to jam.

Incorrect tension settings can also cause poor stitches, as the tension determines the tightness of the stitch. It is important to make sure that the tension is not too tight or too loose, as this can affect the quality of the stitch. Finally, clogged needles can cause the thread to break during sewing, resulting in a poor stitch and potentially even damaging the fabric.

A serger sewing machine is a great tool for anyone who enjoys sewing projects. With proper care and maintenance, it can last for years and provide you with reliable and professional results. With practice and following the machine’s manual correctly, anyone can learn to successfully use a serger machine and make their sewing projects look neat, professional, and polished.