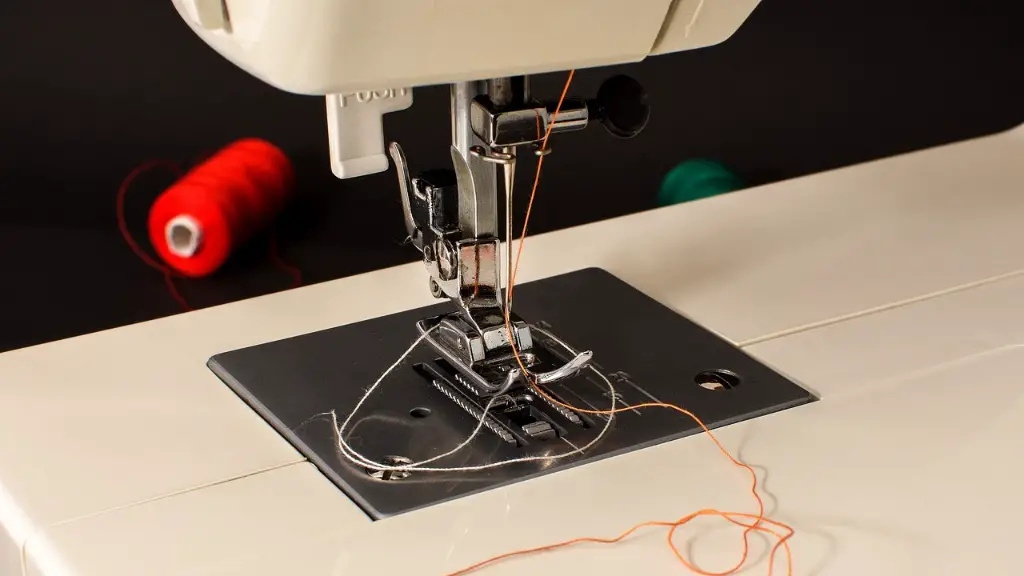

Sewing is a fabricating process where material is joined together to create a garment, usually with the use of a needle and thread. Tailors and seamstresses use this method to create custom clothing, and it is also commonly used to repair existing garments. Sewing can be done by hand or by machine, and the stitching can be done in a variety of different patterns depending on the desired result.

Yes, sewing is a fabrication process.

What is fabrication in sewing?

Fabrication is an important aspect of fashion design. The choice of fabric can make or break a garment. A designer must be able to select the right fabric for their style or line of clothing. The same style is often produced in more than one fabric. This allows the consumer to choose the fabric that best suits their needs.

Fabric construction is the process of converting yarns and fibers into a fabric. The characteristics of the fabric are determined by the materials and methods used. Most fabrics are produced by interlacing, such as weaving or knitting.

What is fashion fabrication

Fashion is not just about what you wear, but how the fabric is made! The Fabrication Process involves structuring the whole Fabric processing to make clothes soft and comfortable according to the industry standards. This makes fashion not just about the clothes you wear, but the comfort and quality of the fabric itself.

This is the main assembly stage of the production process, where sewers stitch fabric pieces together, and a garment is assembled. Computerized sewing machines (costly), can be programmed to sew a specific number of stitches to perform a standard operation, such as setting a zipper or sewing a collar.

What is considered fabrication?

Fabrication is a process of constructing products by combining typically standardised parts using one or more individual processes. For example, steel fabrication is the production of metal structures using a range of processes such as cutting, bending and assembling.

Fabrication or falsification of data is a serious issue in research. It can lead to invalid results and conclusions. There are many examples of fabrication or falsification, including artificially creating data, unauthorized altering or falsifying data, documents, images, music, art or other work. These activities can have serious consequences, so it is important to be aware of them and to avoid them.

What are three types of fabrication?

Cutting is a common fabrication technique in which the material is split or cut into smaller sections.

Punching is a technique in which a tool is used to create a hole in the material.

Shearing is a technique in which the material is cut with a knife or other sharp object.

Stamping is a technique in which a stamp is used to create a pattern or design on the material.

Welding is a technique in which two pieces of material are joined together by heat or pressure.

Cutting is the process of using tools to remove material from the workpiece. This can be done in a variety of ways, but the most common methods are sawing, shearing, and abrasive cutting.

Bending is the process of using tools to shape the workpiece. This is typically done by placing the workpiece in a jig and then using a press to bend it to the desired shape.

Assembling is the process of joining together multiple pieces to create the final product. This is typically done by welding, but can also be done with fasteners or adhesives.

What are the two most common types of fabrication

Welding is a popular fabrication process among crafts enthusiasts because it allows for the joining of two separate metal parts. The process involves the use of heat and pressure to fuse the two pieces together, and results in a strong and permanent bond. There are a variety of welding techniques that can be used, depending on the materials being joined and the desired outcome.

Fabrication is the creation of parts from raw materials, while manufacturing is the process of assembling those parts. In many cases, the two occur together, but there are situations where they may be better suited to a specific project.

For example, if a company needs to mass produce a product, manufacturing would be the better option. But if a company needs to create a prototype or a one-of-a-kind product, fabrication would be the better choice.

What is design fabrication?

Design for Fabrication is a powerful BIM software solution that helps users take their 3D objects to the next level. It provides sophisticated BIM modeling services that allow users to design nearly anything, from simple objects to complex structures. With Design for Fabrication, users can create detailed, accurate models that can be used for fabrication and construction.

A fabricator is someone who manipulates raw materials to create machines and structures. In other words, a fabricator is a type of manufacturer. The services of fabricators are needed to build the parts of a working system and then to maintain it throughout the process.

What is the classification of sewing

Sewing equipment is classified into five categories: MEASURING, CUTTING, MARKING, STITCHING AND PRESSING. Each category has its own unique function and purpose.

MEASURING: Measuring tools are used to take accurate measurements of fabric. This is important in order to create a well-fitted garment.

CUTTING: Cutting tools are used to cut fabric. You will need different cutting tools depending on the type of fabric you are working with.

MARKING: Marking tools are used to mark fabric. This is important in order to create evenly spaced markings on fabric.

STITCHING: Stitching tools are used to stitch fabric. This is important in order to create a well-constructed garment.

PRESSING: Pressing tools are used to press fabric. This is important in order to create a well-pressed garment.

The first step in garment production is pre-production, which includes sourcing fabric and trim, developing fabric, making patterns, and sampling. Production planning is the next step, which involves cutting process, manufacturing, and quality control. Delivery is the last step.

What is the process of making clothes called?

Garment production is an organized activity consisting of sequential processes such as laying, marking, cutting, stitching, checking, finishing, pressing and packaging. This is a process of converting raw materials into finished products.

The main objective of garment production is to create finished products that meet the customer’s specifications and requirements. To achieve this, the various processes involved must be carried out in an efficient and timely manner.

Cutting is one of the most important stages in garment production. It is here that the fabric is cut to the required shape and size. This is usually done using a template or pattern.

After the fabric has been cut, it is then stitched together using a sewing machine. The seams are then checked for strength and durability.

Once the garment has been stitched, it is then pressed and steamed to remove any wrinkles. Finally, it is checked for any faults and then packaged ready for dispatch.

In fabrication process, raw materials are used to create products instead of using ready made components. This type of process is also known as joining process.

What are the examples of fabricated parts

Some examples of products made from fabricated metal include: hand tools, bolts, nuts and screws, cans, cutlery, pipes and pipe fittings, metal windows and doors, equipment attachments, car parts.

There are many different types of fabrication materials, each with its own unique properties and uses. Metals, silicones, and thermoplastics are some of the most common.

Metals are strong and durable, making them ideal for use in structural parts and components. They can also be used for aesthetic purposes, such as in handrails, door hardware, and pipes.

Silicones are heat-resistant and flexible, making them ideal for seals, gaskets, and hoses. They can also be used in molds for casting plastics and other materials.

Thermoplastics are versatile and can be used for a variety of applications, such as in storage tanks, pipes, and insulation. They are also frequently used in the electronics industry.

Final Words

There is no simple answer to this question as it depends on how you define “sewing” and “fabrication process.” If you consider sewing to be any process that involves joining two pieces of fabric together, then it could be considered a fabrication process. However, if you consider sewing to be a specific type of stitching that is used to create a garment or other item, then it might not be considered a fabrication process.

Sewing is a process of creating fabric from thread or yarn. It is used to make clothing, upholstery, and other textile products. Sewing is a fabrication process because it involves the creation of new fabrics from existing materials.