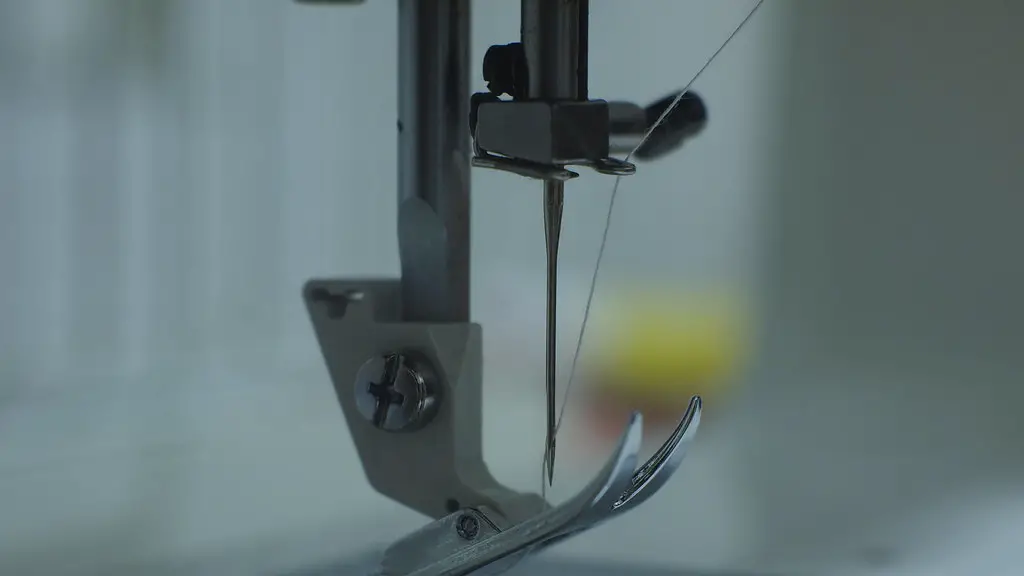

What is a Stretch Needle for Sewing?

A stretch needle is a special type of sew needle used for sewing stretchy fabrics. It is used for knitwear, jerseys, lycra and other elastic fabrics. Stretch needles have an extra large eye and modified grooves on its sides. These modifications ensure that stitches are larger, enabling them to stretch and move with the fabric. Sewing stretch fabrics with regular needles can cause seam fatigue and eventual breakage. The needles are easily identifiable by the red-white colour coding on the shank of the needle.

When sewing with a stretch needle, the feed dog – that is the small teeth underneath the presser foot – should also be set to a lower level. This is because the needle needs to penetrate through the fabric but still allow enough space for the knit stitch to expand when tension is imposed on the fabric. If the feed dog is set too high, it will cause the stitches to penetrate too deep into the fabric, resulting in a weak seam.

Many experts recommend using a ball point needle for all-purpose knitwear fabrics, such as t-shirts, sweatshops, etc. The ball point needle penetrates the fabric without piercing or tearing as it only pushes the fibres of the fabric apart. It is also useful when sewing with lycra, spandex and other stretchy fabrics.

Thread tension is also essential when stitching with a stretch needle. It is important to test the stretch of the seam first. If the thread tension is too tight, the knit stitch may not be able to expand and the seam will eventually tear; if the tension is too loose, the stitch may become slightly distorted.

The Different Types of Stretch Needles

There are several types of stretch needles available depending on the type of fabric you are sewing. The Universal stretch needle is a good general-purpose needle used for all types of knitwear fabrics. It has a medium-length eye and rounded scarf, both of which helps avoid skipped stitches when sewing with elastic fabrics.

The “Stretch twin” needle is the most popular stretch needle. It can be identified by the two grooves that run along the sides of the needle. It is best suited for medium weight to heavy-weight knitwear fabrics and other stretchable materials. The two grooves help push the two threads apart, allowing for more room for the knit stitch to expand.

The “Microtex” or “sharp” needle is the preferred choice for fine and lightweight fabrics. It has an extra sharp point, making it ideal for sewing on delicate fabric such as satin or silk. It has a much smaller eye than the other types of needles and can reduce thread abrasion and breakage.

Finally, an Overlocker or Serger needle is usually used with an over lock stitch, which is a sewing technique used to join two pieces of fabric together. It also has an extra long scarf which helps to eliminate skipped stitches.

Tips for Using a Stretch Needle

When using a stretch needle for the first time, it is important to test the thread tension and fabric before starting a project. Ensure that the thread tension is appropriate for the chosen fabric and that the fabric itself is not stretched too tightly as this can lead to puckered seams and an overall poor quality finish. It is also important to reduce the pressure on the presser foot as this can lead to skipped stitches.

Next, ensure that the needle itself is properly inserted into the machines needle clamp; if it is not installed properly, it can cause skipped stitches and uneven seams. It is also important to use a stretch stabiliser or a knit interlining on the wrong side of the fabric before stitching. This will help prevent the stitches from stretching out of shape when tension is applied to the fabric.

Finally, when changing the type of needle, it is essential to adjust the pressure of the presser foot. When working with stretch fabrics, it is generally recommended to reduce the pressure of the presser foot slightly to allow the fabric to move through the machine freely.

Frequently Asked Questions about Stretch Needles

Q: What is the difference between a regular needle and a stretch needle?

A: A stretch needle has an extra large eye and special grooves on the sides of the needle that make the stitch larger, allowing it to stretch and move with the fabric. Regular needles cannot do this and will eventually cause a seam to tear when the fabric is stretched.

Q: Are stretch needles difficult to use?

A: No. As long as the correct needle is chosen, the correct thread tension is set and the presser foot pressure is appropriately adjusted, sewing with a stretch needle is no more difficult than sewing with a regular needle.

Q: What type of fabric is best to use with a stretch needle?

A: A universal stretch needle is best for general-purpose knitwear fabric such as t-shirts and sweatshirts. For finer fabric such as silk and satin, a “microtex” or “sharp” needle is usually recommended. For elastic fabrics such as lycra and spandex, a “stretch twin” needle is the best option.

The Benefits of Using a Stretch Needle

Using a stretch needle when sewing stretchy fabrics has numerous benefits. As the needle is able to move with the fabric, it prevents the tension of the fabric from pulling or tearing the seams. It also ensures that the seams remain intact and elastic, giving garments a professional, polished finish. When the correct needle is used, it also reduces thread abrasion and breakage, minimising waste and preserving your machine’s performance.

Using the right stitches and stitch length when sewing stretchy fabrics is also essential. For uniforms and jerseys, a 3-step zigzag stitch is generally recommended as it allows for some stretch without distorting the stitch pattern. For heavier fabrics, such as denim, a 4-step zigzag can be used. It is also important to adjust the stitch length for maximum elasticity; a shorter stitch length will allow more elasticity and a longer stitch length will provide a firmer seam.

Finally, using a stretch needle can be beneficial from a cost perspective. Investing in the correct needles can save time and money in the long run as they reduce the possibility of seam failure and prevent the need for repairs and costly replacements.

Alternatives to Stretch Needles

Besides using stretch needles, there are other methods of stitching stretchy fabrics. An overlocker or serger machine is a good option as the stitch it produces is strong and durable. It is also perfect for finishing the edges of the fabric, and it is particularly useful for sportswear and activewear. The stitch is a combination of a straight stitch and an overlock stitch, and it also gives the fabric a professional, polished finish. It is also a lot faster to stitch with an overlocker than with a traditional sewing machine.

Lycra and spandex can also be sewn together using a wide zigzag stitch. This is the most common stitch used for these fabrics as it allows the fabric to stretch without breaking the stitches. It is also relatively easy to set up the machine for this type of stitch, making it a popular choice for beginners.

Another option for sewing stretchy fabric is the overedge stitch, also known as the overcasting stitch. This stitch has a much wider zigzag than the regular zigzag and is used to finish the edges of the fabric to prevent fraying and unravelling. It is usually used in combination with the straight stitch, providing strong and secure seams.

Pre-Stretching Fabrics Before Sewing

Pre-stretching the fabric before sewing is always recommended. This helps to maintain the fabrics shape and structure and can also help reduce the possibility of seam failure. Pre-stretching should be done by hand, and it is important to ensure that the fabric is stretched evenly in all directions. When pre-stretching, it is also important not to pull the fabric too hard as this can distort the shape of the fabric.

It is also important to note that not all fabrics need to be pre-stretched before sewing. Some fabrics, such as corduroy and twill, can be sewn without pre-stretching as the fabric will stretch during the sewing process. On the other hand, stretch fabrics such as lycra and spandex should always be pre-stretched before sewing.

Before starting a project, it is also important to consider other factors such as the weight and thickness of the fabric. Lightweight and thin fabric should be handled with care, as it is more likely to stretch and distort during the sewing process. Heavier and thicker fabrics, such as denim, usually require a heavier duty sewing machine and a stronger needle.

Tips to Prevent Seam Failure

Choosing the right needle, adjusting the thread tension and presser foot pressure, and pre-stretching the fabric are all important steps for ensuring successful sewing. It is also important to note that some fabrics, such as elastic and Lycra, require a special type of thread known as “stretch thread”. This type of thread is designed to stretch with the fabric, providing a more secure and elastic seam.

Finally, it is important to check the seams before finishing a project. Stress test the seams to ensure that the stitches are not pulling or tearing and check for missed stitches. If any of these issues are present, it is important to fix them before continuing. This will help to ensure a professional, polished finish.