Reasons Causes Thread to Break

Having trouble with your threads breaking while you’re using your sewing machine? It can be really annoying and lead to wasted time, fabric, and energy. You’ll be happy to know that there are some common culprits when it comes to why your threads break so often. Keep reading to learn all the reasons why the thread continues to snap on the sewing machine and what you can do to prevent this from happening.

Choosing the Wrong Thread

One of the most common reasons why the thread will break on a sewing machine is due to the wrong thread being used for the material you are working on. Different fabrics require different thread weights, and if you aren’t using the correct weight of thread for the material, it is likely that the thread will break more often. Be sure to check the needles and thread weight before beginning your project to make sure that you are using the correct type of thread for the fabric.

Needle Not Compatible

Another common reason why the thread is breaking is due to the needle not being compatible with the material you are sewing on. The size and type of needle are important when it comes to getting a successful stitch, and if you are using the wrong needle type then the thread is likely to break more often. Be sure to use the right needle for your fabric to avoid having issues with the thread snapping.

Thread Over Tension

Thread tension is also a factor when it comes to why the thread keeps breaking. Too much tension can cause the thread to break, so be sure to carefully adjust the tension dial until it is balanced. This will help ensure that the thread isn’t breaking too often.

Poorly Adjusted Bobbin

Another common culprit is a poorly adjusted bobbin. It should be adjusted so that it spins at the correct rate and tension. If this isn’t adjusted properly, the thread will snap more often. Take a moment to check that your bobbin is adjusted correctly before beginning your project.

Dull Needles

Using dull needles is also a common reason why the thread will break often. The needle should be sharpened before each use in order to get a successful stitch. If the needles are dull, then the thread is likely to break more often. Be sure to check that the needles you are using are sharp and replace them if necessary.

Old Thread

Using old thread can also lead to thread breakage. Old thread is weak and more prone to snapping, so if you have an old spool of thread it is best to replace it before using it on your machine. This will help ensure that you don’t run into any issues with the thread snapping.

Solutions for Thread Breaking

Now that you know the common reasons why your thread is breaking, it’s time to learn about some potential solutions. These tips will help you troubleshoot and prevent the thread from breaking so often on your machine.

Test Stitch

Do a test stitch on a scrap of fabric to make sure that your needle and thread combination is correct. This will help you to identify any potential issues with the combination so that you can address them before starting your project.

Ensure Thread is Not Tangled

Make sure that the thread is not tangled up when threading your machine. A tangled thread can cause tension issues which can lead to the thread breaking more often. To avoid any tangles, be sure to keep the spool of thread away from any potential sources of tangles.

Slow Down the Machine

If you find that your thread is still snapping, try slowing down the speed of your machine. This will help reduce the amount of tension on the thread and make it less likely to break.

Check Tension

Make sure the tension is adjusted properly. Too much tension can lead to the thread breaking, so be sure to take the time to adjust the tension dial so that it is balanced.

Change Needle Frequently

Be sure to replace the needle frequently, as needles can become dull over time and cause the thread to break more often. This will help ensure that you have a sharp, needle that is capable of properly piercing the fabric.

Troubleshooting Thread Sears

Thread tension isn’t the only issue that can cause the thread to break on your sewing machine. There are a few other things that you can check which may be the cause of the problem.

Check the Bobbin

Make sure that the bobbin is correctly inserted into the machine and adjusted correctly. This will help to ensure that the thread is being pulled through the fabric properly.

Check the Top Thread Tension

Be sure to check the tension of the thread on the top of the machine as well. Too much tension can lead to the thread breaking more often, even if the bobbin tension is set correctly.

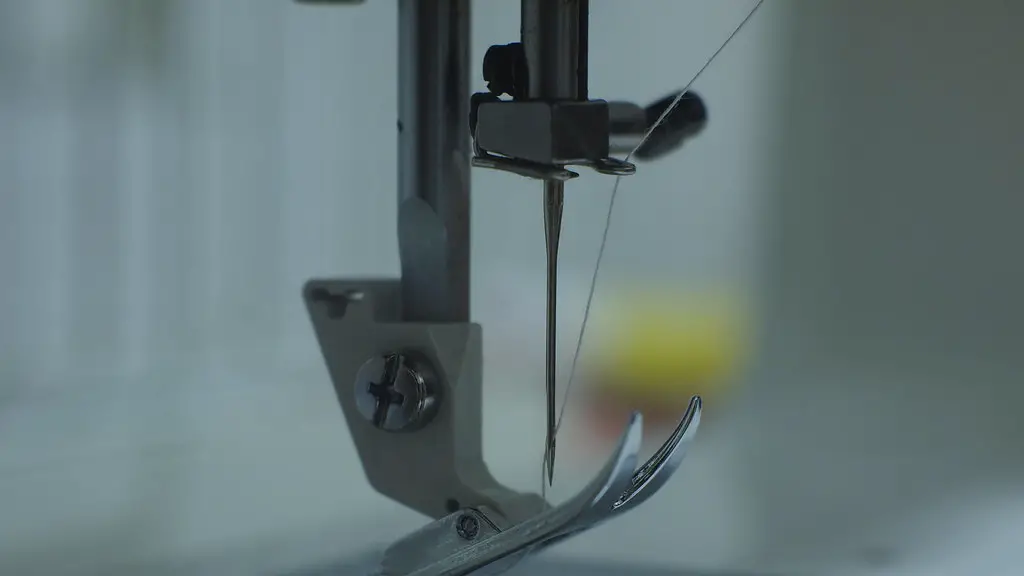

Check the Presser Foot

Make sure the presser foot is installed correctly and that the screw is tightened properly. This will help ensure that the fabric is being fed through the machine properly, reducing the chances of the thread snapping.

Check the Needle

Be sure to check the needle for any damage that may be causing the thread to break more often. If the needle is bent or damaged in any way, it should be replaced before continuing.

Check Thread Path

Make sure that the thread is following the correct path through the machine. If the thread isn’t following the correct route, then it is likely to snap more often. Take a moment to check that the thread is taking the correct route through the machine.

Preventive Maintenance of Machine

In order to keep your sewing machine running properly and to keep the thread from breaking, it is important to do some preventive maintenance on a regular basis. This will help reduce the chances of the thread breaking, and will also help to keep your machine in good condition.

Clean Machine

Be sure to clean your machine regularly. This will help to remove any dust, lint, or fibers that may be clogging up the works of the machine and causing tension issues.

Oil Machine

Oil your machine on a regular basis. This will help to keep the moving parts of the machine lubricated and running smoothly. This will help reduce the chances of the thread breaking.

Check Threads & Needles

Be sure to check the threads and needles on a regular basis to make sure that they are in good condition. If you find that the threads or needles are worn or damaged, be sure to replace them before continuing.

Quality Thread

Always use quality threads for your projects. Lower quality threads will break more easily and cause more issues with your machine.

Check Settings

Take a few minutes to check the settings on your machine to make sure that they are adjusted correctly. Adjusting the speed and tension can help to reduce the chance of the thread breaking.

Thread Troubleshooting Tips

Though the thread can be a tricky issue on the sewing machine, it doesn’t have to be difficult if you have the right troubleshooting tips. Here are some tips that can help you if you find that your thread keeps breaking.

Check Your Habits

Start by taking a look at your own sewing habits. If you are sewing too quickly or pushing fabric through the machine at a high speed, it can lead to the thread snapping more often.

Check Thread Tension

Be sure to check the thread tension on a regular basis. If the tension is off, it can cause the thread to break.

Check Thread Path

Make sure that the thread is following its correct path through the machine. If there are any kinks or snags in the thread, be sure to fix them before continuing.

Check Needles

Be sure to check the needles on a regular basis to ensure that they are in good working order. If the needle is bent or damaged in any way, be sure to replace it.

Practice Needle Threading

Practice threading the needle. This will help ensure that you are threading the needle properly and reduce the chances of the thread breaking.

Preventative Maintenance Habits

In order to avoid having any more issues with the thread breaking on the sewing machine, it is important to get into some good preventative maintenance habits. These are some important habits to get into:

Regular Cleaning

Be sure to clean your machine on a regular basis to remove any dust, lint, and fibers that could be clogging up the works of the machine and causing tension issues.

Regular Lubrication

Oil the machine on a regular basis to keep the moving parts lubricated and working smoothly. This will help to reduce the chance of the thread snapping.

Quality Threads

Always use quality threads for your projects. Lower quality threads are more prone to breaking.

Check Settings

Take a few minutes to check the settings and make sure that they are properly adjusted. This will help to reduce the chances of the thread snapping.

Change Needles Regularly

Be sure to change the needles regularly to ensure that they are sharp. A dull needle can cause the thread to snap more often.