The act of sewing involves passing a threaded needle in and out of fabric. When the needle is pulled out of the fabric, the thread may come out with it. This can be frustrating, especially if the thread is tangled. There are a few reasons why this may happen. The most common reason is that the needle is not properly inserted into the fabric. If the needle is not inserted far enough, the thread will come out when the needle is pulled. Another common reason is that the thread is not properly secured. The thread may come out if it is not tied off or if the knot is not tight enough. Finally, the type of fabric can also affect how likely the thread is to come out. Some fabrics, like silk, are more slippery and make it harder for the thread to grip.

There are several reasons why thread may come out of a needle while sewing. The needle may be the wrong size for the thread, the thread may be damaged, the needle may be dull, or the tension on the thread may be too loose.

How do I stop my thread from coming out of the needle?

When you are removing a needle from fabric, hold the needle at the ‘bottom’, opposite of the pointed end, where the thread is going through the eye. Doing this will prevent the thread from being pulled out.

If your sewing machine’s thread tension is set too high or too low, it can cause the needle to keep unthreading. Make sure to adjust the tension accordingly to avoid this issue.

Why does my sewing machine keep losing top thread

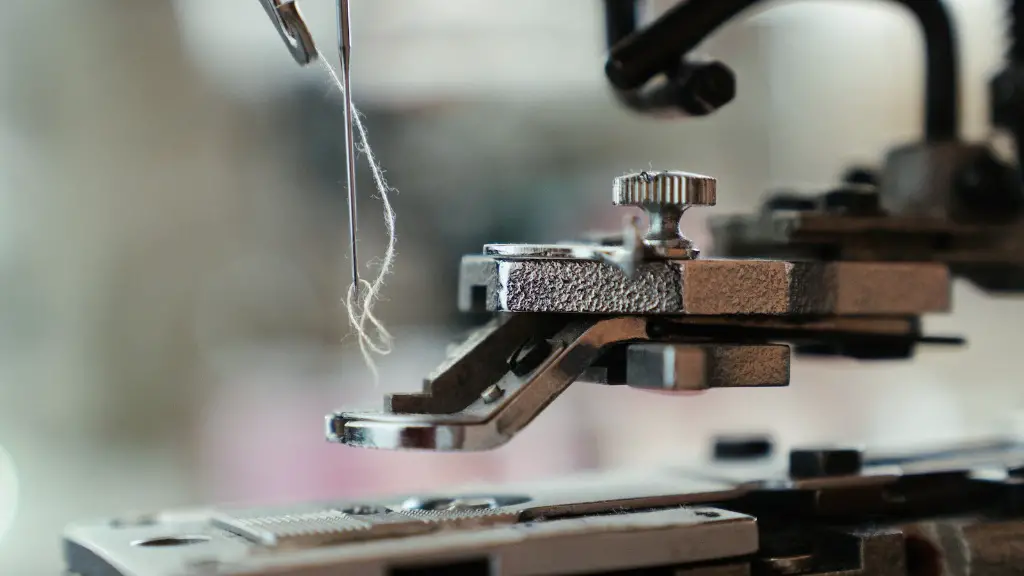

If you’re having trouble with your sewing machine, it could be due to a number of things. One possibility is that the needle is not inserted correctly. Make sure that the flat side of the needle is facing the back, and that the needle is pushed up into the machine as far as possible. Also, check to see if the needle is damaged or bent. If so, replace it with a new one. Another possibility is that the lower thread tension is incorrect.

The dial settings on a sewing machine generally range from 0 to 9, with 45 usually being the ‘default’ position for normal straight-stitch sewing. This setting should be suitable for most fabrics. However, depending on the type of fabric you are working with, you may need to adjust the dial to a different setting in order to get the best results.

How do you tell if your bobbin tension is off?

If you’re having trouble with your bobbin tension, here’s a quick fix. Swiftly pull up on the thread. The thread should unwind just slightly and the bobbin case should drop an inch or two. If the thread unwinds without resistance and the case slips to the floor, your bobbin tension is too loose. If the bobbin case doesn’t budge, your bobbin tension is too tight.

This is a another technique that can be used to get a needle into the eye. You rub your hand with the needle until the eye grabs the threat.

How do you adjust thread tension?

The tension on a string instrument is controlled by the tuning screws. By turning the screws, the string becomes tighter or looser, which changes the pitch of the string. The two screws here control the tension on the string, and by turning them, the tension can be increased or decreased.

If you’re having trouble with your top thread pulling out of your needle when you start to sew, it might be because your needle and take-up lever are not in their highest position. On computerized sewing machines, the needle usually stops in the fabric when you raise the presser foot, which makes it easy to pivot as needed.

How tight should bobbin tension be

Proper bobbin tension is essential to good embroidery. If tension is too tight, unwanted bobbin thread may begin to show on top of your garment, and you may begin to experience frequent thread breaks, which wastes time and money. Bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps).

If your presser foot is down while you’re trying to thread your machine, the tension disks will lock and you won’t be able to thread the machine correctly. Make sure the presser foot is up before you start threading.

What number is tighter tension on sewing machine?

When you’re adjusting the upper thread tension on your machine, remember that a higher number on the dial indicates a higher (tighter) tension, and a lower number indicates a lower (looser) tension.

When you are sewing a straight stitch, you will want to set your machine to the appropriate stitch length. This will ensure that your stitches are even and consistent. A good rule of thumb is to set your machine to a stitch length of approximately 2-25mm. This will give you nice, even stitches that are perfect for a straight seam.

What stitch length should I use

The best stitch length to use depends on the project you are working on and the type of fabric you are using. For a standard stitch length, use a 25-30 stitch length. For a basting stitch, use a 50-70 stitch length. For stay-stitching, use a 15-20 stitch length. And for top-stitching, use a 30-35 stitch length.

This is a guide for adjusting the tension on your sewing machine. If the bobbin case doesn’t move at all when you jerk it, the tension is too tight and you need to decrease the tension for sewing with this thread. If the bobbin case drops quickly, the tension is too loose and you need to increase the tension.

What tension should a sewing machine be for thick fabric?

When stitching thick fabric, it is important to use the correct tension. A tension of 35 to 45 is recommended for fabrics such as denim or leather. This will allow you to sew through the fabric easily and maintain a neat finish.

If your sewing machine is not sewing properly, there are a number of possible causes. The top or bobbin thread may not be set correctly, the thread may not match the needle, or the thread tension setting may not be properly set.

Conclusion

There are a few reasons why this might happen. The needle could be too small for the thread, the thread could be fraying, or the needle could be too blunt.

The reason that thread can come out of a needle when sewing is because the needle is not properlyThreading the needle correctly can help to prevent this from happening.