If you’re finding that your sewing machine is breaking needles more often than it used to, there are a few potential causes. First, check to see if the needles you’re using are the correct size and type for your machine. Second, take a look at your sewing machine’s needle plate and see if there are any nicks or burrs that could be causing the needles to break. Finally, check your thread tension to make sure it’s not too tight, as this can also cause needles to break. By troubleshooting these potential problems, you should be able to fix the issue and get back to sewing.

There are several possible reasons for your sewing machine breaking needles. One possibility is that your machine is not properly threaded. Make sure that you are following your machine’s specific threading instructions. Another possibility is that your needle is not properly inserted into the needle bar. Again, consult your machine’s manual for the proper way to insert the needle. Additionally, be sure to use the correct type of needle for your fabric and sewing project. Using the wrong type of needle can cause it to break more easily. Finally, check to see if your sewing machine’s tension needs to be adjusted. If the tension is too loose, the needle can break more easily.

Why does the needle keep breaking in my sewing machine?

If you’re having trouble with your needles breaking, one possible cause is an incorrectly placed bobbin case. Always make sure that your bobbin is properly loaded in its case, and the case is inserted correctly. This will help to avoid the needle hitting the bobbin case and breaking.

Skipped stitches are a common sewing issue that can be caused by a number of factors. Bent or deflecting needles are one common cause, so be sure to use a reinforced needle and reset the needle guard. Incorrect tension in either the needle or under the threads can also cause skipped stitches, so be sure to readjust the tension settings.

Why does my Brother sewing machine needle keep breaking

If you are having trouble with your sewing machine, there are a few things you can check. First, make sure that the needle is correctly inserted with the flat side facing the back. If the needle is damaged or bent, replace it with a new one. Second, make sure that the fabric is not pulled excessively when sewing. If you are still having problems, consult the sewing machine manual or take it to a professional for help.

While holding the needle with your left hand, tighten the needle clamp screw by twisting it away from you. Be sure not to overtighten the screw, as this may damage the needle.

How do you prevent needle thread breakage?

This is what happens when your needle thread breaks:

Check that the thread on the spool is not tangled. If it is, gently untangle it.

Re-thread the needle, making sure that the thread is correctly positioned in the needle eye and that the tail end of the thread is not pulled through the needle eye.

Pull the thread tail to the wrong side of the fabric and hold it there while you continue sewing.

If your needle is not inserted properly, your thread may break. Make sure the eye of the needle is facing the front, and that the scarf (indent) of the needle is facing the back. Burrs in the needle may also cause the thread to shred. It’s also important to check up on your needles from time to time.

How common is needle breakage?

Needle breakage during an infiltration is uncommon, but it can happen. usually, it’s a complication of an inferior alveolar nerve block. only one needle breakage has been reported in the literature.

Sewing machines are a great tool for any sewer, but they’re not perfect. Here are some common sewing machine problems and how to solve them.

1. Thread bunching up under your fabric when sewing – This is usually caused by the needle being too low. Raise the needle and try again.

2. Bent or broken needles – Change the needle and try again.

3. Fabric not feeding – This can be caused by several things. Check that the feed dogs are down and that the presser foot is up. Also, make sure that the tension is not too tight.

4. Thread keeps breaking – This is usually caused by the needle being too low. Raise the needle and try again.

5. Machine is skipping stitches – This can be caused by several things. Check that the needle is inserted correctly and that the tension is not too tight.

6. Bobbin tension not consistent – This can be caused by several things. Check that the bobbin is inserted correctly and that the tension is not too tight.

7. Seams in stretch fabrics coming out wavy – This can be caused by several things. Check that the needle is inserted correctly and that the tension is not too tight

How long do sewing machines last

Sewing machines are designed to withstand a lot of use and abuse. However, like any other machine, they will eventually wear out. The typical life expectancy of a sewing machine is five to 25 years, depending on the make and model, as well as the conditions it is exposed to.

factors that will affect a sewing machine’s lifespan include:

• Frequency of use: The more often a sewing machine is used, the shorter its lifespan will be.

• Type of use: If a sewing machine is used for heavy-duty projects, such as sewing through multiple layers of fabric or leather, it will not last as long as one that is used for lighter projects.

• Quality of care: A sewing machine that is well-oiled and cleaned on a regular basis will last longer than one that is neglected.

• Environmental conditions: A sewing machine that is stored in a dry, dust-free environment will last longer than one that is exposed to extreme heat, cold or moisture.

If you’re having trouble with your sewing machine needle, make sure that the flat spot on the needle is facing the back of the machine. Additionally, check to see if the needle clamp screw is loose – if it is, tighten it up and see if that fixes the problem.

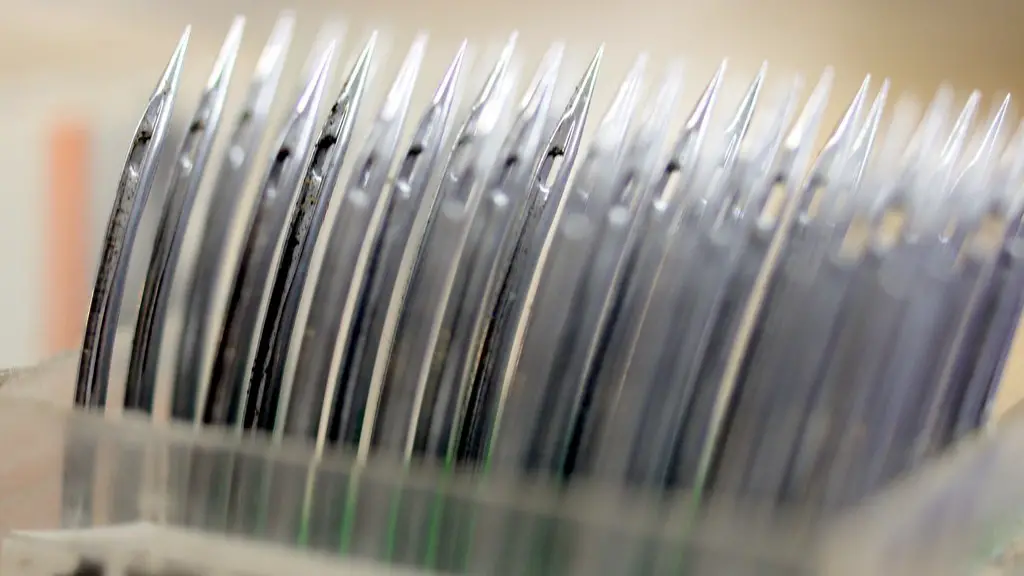

How long does a sewing machine needle last?

Sewing needles generally have a shorter lifespan than other types of needles because they can become dull quickly from piercing through fabric. It is important to change your sewing needle often to avoid any headaches caused by uneven stitches or tugs in your fabric.

You unscrew this black knob with the tool that’s provided with you for you after the needle will pop out. You will see a small, black, circular object with a needle in the center of it. This is the carbon filter. You will need to unscrew the top of the carbon filter (the part that has the needle in it) and throw away the needle. Then, you will screw the top back on and put the carbon filter back in the black knob.

What should the tension be set on a sewing machine

The dial settings on a sewing machine typically range from 0 to 9, with 45 generally being the “default” position for normal straight-stitch sewing. This setting should be suitable for most fabrics. However, depending on the fabric and the desired finished look, it may be necessary to adjust the dial to a higher or lower setting.

Hi,

If you’re having trouble with your needle hitting the needle plate, it’s possible that you have the wrong needle plate on the machine. Make sure that everything is as it should be, and if the problem persists, you’ll need to take it to the dealer to have it fixed. There may be something out of alignment.

Does cheap thread break when sewing?

It can be difficult to thread a spool of thread because it can be too heavy or too big and it may get stuck.

Thread breaks are usually caused by tension issues, thread path interference, old thread or poor digitizing. Thread frays have more to do with burrs and nicks in the thread path.

Final Words

The most likely reason why your sewing machine is breaking needles is that the needle is not properly inserted into the needle clamp. Make sure that the needle is inserted all the way into the needle clamp and that the flat side of the needle is facing the back of the machine. Also, check to see if the needle is bent or blunt. If the needle is bent or blunt, it will need to be replaced.

There could be several reasons for your sewing machine needles to break. One reason could be that you are using the wrong type of needle for your fabric. Another reason could be that your machine is not properly lubricated, causing the needles to overheat and break. Additionally, your machine may be Threading improperly, which can cause the needle to bend and break. Finally, you may simply be using needles that are too old and worn out. Regardless of the reason, needles breaking can be a frustrating sewing experience.