If your sewing machine needle is stuck, there are a few possible reasons. The most common reason is that the needle is inserted incorrectly. If the needle is not inserted all the way into the machine, it can become stuck. Another possible reason is that the needle is dull or damaged. If the needle is dull, it can cause the thread to break or snag, which can lead to the needle getting stuck. If the needle is damaged, it can also lead to the needle getting stuck.

The sewing machine needle may be stuck for several reasons. The most common reason is that the needle is not aligned properly with the needle bar. To fix this, first make sure that the needle is inserted all the way into the needle bar. Then, using a small screwdriver, turn the set screw on the needle bar until the needle is aligned with the center of the hole in the needle bar. If the needle is still stuck, the problem may be that the needle is bent or the needle bar is damaged. In this case, you will need to replace the needle or the needle bar.

What do you do if your sewing machine needle gets stuck?

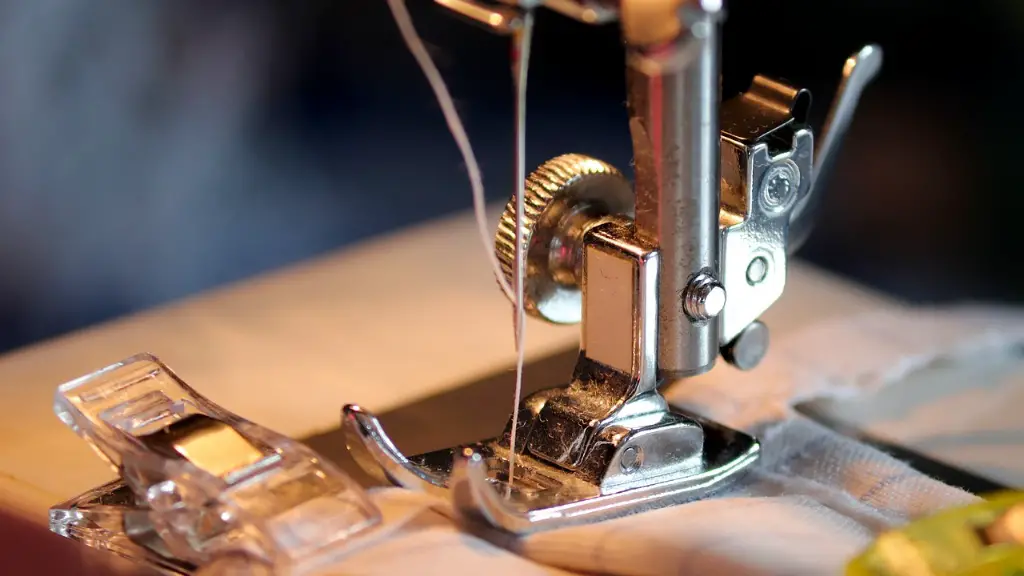

If you are having trouble with your needle becoming stuck in the fabric, there are a few things you can check. First, make sure you are using the correct size needle and thread combination for your machine. Second, loosen the presser foot screw and the needle clamp screw to remove the presser foot holder and the needle from the machine. Finally, use the oval screwdriver to remove the two screws securing the needle plate.

If your machine is jammed, it could be for a number of reasons. Sometimes it’s a tension issue, sometimes the thread doesn’t quite catch, and sometimes your needle is slightly bent – even if you can’t see it. To fix a jammed machine, you’ll need to troubleshoot the issue to identify the root cause. Once you know what’s causing the problem, you can take the necessary steps to fix it.

How do you release a sewing machine needle

You will want to undo This generally that’s turning it to the left whilst You do this hold on to the end of the string so it doesn’t come undone as you turn.

First, make sure the bobbin-winding spindle (located on top of your machine) has been pushed back to the left for sewing. If it is not in the correct position, the needle will not go down and pick-up your bobbin thread.

Why won’t my sewing machine needle move up and down?

If the needle on your sewing machine isn’t moving when you engage the clutch, the first thing you should do is unplug the machine and check the drive belt. If the belt is broken, you’ll need to replace it. If the belt is okay, the problem is likely due to an internal drive gear failure.

If the needle thread tension is too tight, you will need to loosen it. This can be done by adjusting the tension knob on your sewing machine.

What is the most common problem for a sewing machine?

Common sewing problems can be frustrating, but there are a few things you can do to troubleshoot them. If you’re having needle thread breakage, check to see if your needle is bent or damaged. If your bobbin or looper thread is breaking, make sure that it is correctly inserted and that the tension is not too tight. If your thread is fusing when the machine stops, increase the stitch length. Skipped stitches can be caused by a number of things, including a dull needle, incorrect thread tension, or incorrect stitch width. Imbalanced or variable stitching can be caused by a number of things, including incorrect needle size or poor thread quality. Staggered stitching can be caused by a number of things, including incorrect needle size or poor thread quality. Variable stitch density can be caused by a number of things, including incorrect needle size or poor thread quality. Seam pucker can be caused by a number of things, including incorrect needle size or poor thread quality.

The entire process of taking this out and unlocking it can be quite tedious and time-consuming. Make sure that you have everything you need before starting so that you can avoid any unnecessary delays.

How do you move the needle position on a sewing machine

The needle position can be adjusted on a sewing machine by pressing the “+” key to move the needle to the right, or the “-” key to move the needle to the left. This is useful for achieving different stitch widths on a garment.

The handwheel is an important part of the sewing machine as it allows you to raise and lower the needle. This is important in order to create the right stitch density and ensure that your fabric is not damaged.

Why is my sewing machine not threading the needle?

If the needle is installed incorrectly, damaged, or bent, it can cause the automatic needle threader to fail. Make sure the needle is installed correctly and is not damaged or bent. Also, make sure you are using the correct size needle for the type of thread you are using. If the hook on the needle threader is damaged, it may need to be replaced.

The hand wheel on a sewing machine lets you manually move the needle up and down. The backstitch lever is used to make the machine sew in reverse. The thread spool pin holds the spool of thread for the top thread of the machine.

Why is the needle not moving on sewing machine Brother

This is a common problem with sewing machines. If you press harder and the machine makes a noise except the needle does not move up or down, your belt has come off the pulley on the motor. You will need to open up the sewing machine and put the belt back on the pulley.

The handwheel is an important part of the sewing machine. It is used to adjust the needle height and make manual stitches. It is also used to lower the needle before starting to sew. You should always turn the handwheel towards you when you use it.

Why is the tension so tight on my sewing machine?

This is an important principle to remember when sewing: the more threads in the stitch, the looser the stitch will be, and the less threads, the tighter the stitch will be. Top thread tension is controlled by a dial on the machine’s thread path, so make sure the thread sits correctly between the tension discs when you’re threading your machine.

This is an easy problem to fix. First, take a small brush and brush out your tension disks. Next, clean out your bobbin case and under the case. Finally, oil things if your machine requires it.

Conclusion

There are a few possible reasons why your sewing machine needle might be stuck. One possibility is that the needle is not properly inserted into the needle clamp. Another possibility is that the needle is bent or damaged. Finally, it is possible that there is something blocking the needle from moving freely. If you are not sure what is causing the problem, it is best to take your sewing machine to a qualified technician for diagnosis and repairs.

There are a few reasons why your sewing machine needle may be stuck. One reason could be that the needle is not fully inserted into the needle clamp. Another reason could be that the tension disk is not properly engaged. Finally, the needle could be dull or bent, which would cause it to get stuck in the fabric.