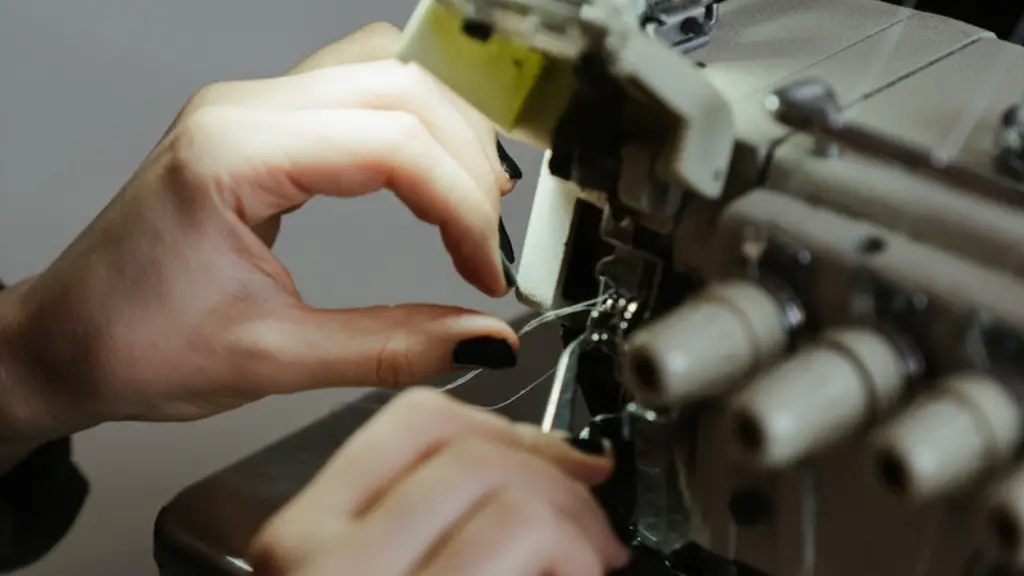

A sewing machine needle is designed to withstand a certain amount of pressure and wear; however, if it is used improperly, it can break. There are a few reasons why a sewing machine needle might break, including using the wrong type of needle for the fabric being sewn, sewing too quickly, or sewing through a knot in the fabric. Additionally, a dull needle is more likely to break than a sharp one, so it is important to change the needle frequently. If a sewing machine needle keep breaking, it is likely due to one of these factors.

The most common reason for a sewing machine needle to break is if it is bent or blunt. Sometimes a needle can also break if it is not inserted properly into the needle bar. If the needle is not all the way in the bar, or if it is not inserted at the correct angle, it can cause the needle to break.

What is the remedy for needle breaking?

If you notice skipped stitches while you’re sewing, there are a few possible causes and remedies. First, check to see if your needle is deflecting or bent. If so, switch to a reinforced needle and reset the needle guard. You may also need to replace the needle. Another possible cause is incorrect tension in the needle or under threads. In this case, re-adjust the tensions until they’re even.

Threads can break if your needle is not inserted properly. Make sure the eye of the needle is facing the front (not slanted) and that the scarf (indent) of the needle is facing the back. Burrs in the needle may also cause the thread to shred. It’s also important to check up on your needles from time to time.

How can we avoid needle from breaking

If the needle keeps breaking, make sure the needle is inserted correctly and that the fabric is not pulled too much when sewing. Also, check for damage or bent needles.

While holding the needle with your left hand, tighten the needle clamp screw by twisting it away from you. This will secure the needle to the syringe. Next, take the cap off of the needle and screw it onto the syringe. Make sure that the cap is tight so that the needle does not come loose. Finally, insert the needle into the rubber stopper of the medication vial.

How common is needle breakage?

Needle breakage during an infiltration is a rare complication, typically occurring with inferior alveolar nerve blocks. Only one case has been reported in the literature.

The dial on most sewing machines is adjustable, and the settings run from 0 to 9. The setting of 45 is generally the ‘default’ position for normal straight-stitch sewing, and should be suitable for most fabrics. However, it is always best to test the stitch on a scrap piece of fabric before sewing on the project itself, to ensure that the stitch is the right size and tension for the fabric.

How do I stop my thread from breaking on my sewing machine?

Before threading the machine, make sure the spool of thread is installed correctly using the correct size spool cap for the size of spool. For details, refer to the manual and “Place a spool of thread on a spool pin” section.

Make sure the needle is correctly inserted with the flat side facing the back and pushed up into the machine as far as possible.

If your needle gets too bent, it can hit your feed dogs, throat plate, or bobbin case, and break. To avoid bending your needle, try to slow down while you’re sewing or use a sharper needle.

What are the six sewing machine troubles

Here are some common sewing machine problems and how to solve them:

1. Thread bunching up under your fabric when sewing: This can be caused by a number of things, such as the thread being too tight, the needle not being inserted properly, or the tension being too loose. To fix this, first check the thread tension and make sure it is not too tight. Then, make sure the needle is inserted properly and that the tension is not too loose. If the problem persists, try using a different type of thread.

2. Bent or broken needles: This is usually caused by sewing over a pin or other sharp object. To fix this, simply replace the needle with a new one.

3. Fabric not feeding: This can be caused by the fabric being too thick, the tension being too loose, or the feed dogs being lowered. To fix this, first increase the tension and then try feeding the fabric through again. If the problem persists, try using a thinner fabric.

4. Thread keeps breaking: This can be caused by the thread being too old, the tension being too tight, or the needle being too blunt. To fix this, first check the tension and make sure it is not too tight. Then

If the needle is not fitted properly in the machine, it can cause a number of problems. The needle clamp screw may be loose, which can cause the needle to move around and not sew properly. The best way to fix this is to firmly tighten the needle set screw.

How do you tighten a sewing machine needle?

Either using your fingers or perhaps the tool that’s come with your sewing machine, you must make sure that the needle is inserted correctly into the fabric. The needle should be inserted at a 90 degree angle to the fabric, with the eye of the needle facing upwards. Otherwise, you risk making a hole in the fabric or breaking the needle.

If you’re looking to buy a new sewing machine, the first thing you should know is that the needles are standardized. This means that they are compatible across all brands, including Janome, Brother, Husqvarna, Elna, and Pfaff. This is important to know because it means that you can shop around and compare prices without having to worry about compatibility.

What is the biggest cause of needle stick injury

Since syringe needle heads and angiocatheter are the main causes of needlestick injuries, providing safe medical equipment should also be emphasized. Some safety tips for medical equipment include:

-Choose needleless systems whenever possible

-Encourage the use of safety engineered medical devices

-Make sure all medical equipment is properly labelled

-Never re-use needles or syringes

-Ensure medical equipment is properly maintained and cleaned

If you are handling contaminated needles, be sure to follow proper protocol and dispose of them in a sharps container. Do not remove, recap, break, or bend the needles, as this could increase the risk of a needlestick injury or exposure to a bloodborne pathogen.

How quickly do needle holes heal?

If you have a wound that is taking a long time to heal, it is important to watch for any signs of infection. Symptoms of infection might include swelling, redness, pain, or pus coming from the wound. If you notice any of these symptoms, call the doctor right away.

If you’re having trouble with your bobbin tension, make sure to check the following:

-The thread should unwind just slightly when you pull on it. If it unwinds without resistance, the bobbin tension is too loose.

-The bobbin case should drop an inch or two when you pull on the thread. If it doesn’t budge, the bobbin tension is too tight.

Final Words

The most common reason for a sewing machine needle to break is because it is bent. Bending can happen when the needle hits something hard, like a pin in the fabric, or when the fabric is pulled too hard while sewing.

The most common reason for a sewing machine needle to break is that it is not properly positioned in the machine. The needle should be lined up with the presser foot, and the tension should be set properly. If the needle is not properly positioned or the tension is not set properly, the needle will be forced to the side and will eventually break.