If your sewing machine needle won’t go up and down, there are a few possible causes. The most common cause is that the needle is not properly inserted into the needle bar. If the needle is not all the way in the needle bar, it will not be able to move up and down. Another possible cause is that the needle is bent. A bent needle will also not be able to move up and down. Finally, the problem could be with the needle bar itself. If the needle bar is damaged, it will not be able to move the needle up and down.

There are a few reasons why your sewing machine needle might not be going up and down. The most common reason is that the needle is not properly inserted into the machine. If the needle is not inserted all the way, or if it is not inserted properly, it will not be able to move up and down. Another reason why the needle might not be moving is because the tension is not set correctly. The tension on a sewing machine is what controls the movement of the needle. If the tension is too loose, the needle will not move. If the tension is too tight, the needle will break.

Why won t my Singer needle go up and down?

If you are having trouble with your needle not picking up your bobbin thread, make sure that the bobbin-winding spindle is in the correct position. It should be pushed back to the left for sewing. If it is not in the correct position, the needle will not go down and pick up your bobbin thread.

If the needle bar on your sewing machine does not move up or down, there are a few possible causes. First, check the position switch to make sure the feed dogs are in the raised position. If they are lowered, the needle bar will not be able to move. Second, check the stitch length setting. If it is set to 0, the needle bar will not move. lengthen the stitch length on your machine. Third, make sure you have the correct pressure foot on the machine. The wrong pressure foot can cause the needle bar to not move. Finally, check for tangled thread. If the thread is tangled, it will need to be removed before the needle bar will be able to move.

Why doesn’t my sewing machine needle line up

This is normal, as there is no adjustment on the Featherweight for the position of the needle.

A sewing machine jam can be a real pain, especially if you’re in the middle of a project. There are several things that can cause a machine to jam, such as a tangled thread, uneven fabric feeding, or a build-up of lint or dust. To avoid this, be sure to keep your machine clean and free of any buildup. If you do end up with a jam, try to troubleshoot the issue and fix it so you can get back to sewing!

Why won t my brother sewing machine needle go up and down?

If you press harder on the sewing machine and it makes a noise, but the needle doesn’t move up or down, then the belt has come off the pulley on the motor. You’ll need to put the belt back on before you can continue sewing.

If the handwheel on your sewing machine does not turn or is tight, there are a few things you can try. First, try to turn the handwheel toward the back of the machine to free up the locked handwheel. If that does not work, check to make sure that the upper thread is not tangled up. If the upper thread is not the problem, turn the machine off and unplug it. Then, turn the handwheel toward you once again to see if it is locked.

What manually moves the needle up and down?

The hand wheel on a sewing machine lets you move the needle up and down manually. The backstitch lever is used to make the machine sew backwards. The thread spool pin is where the spool for the top thread of the machine sits.

If you’re worried about pricking your fingers when sewing, you can use silicone or textured rubber gripping pads or finger covers. These will help you get a good hold on the needle and prevent you from pricking yourself. Another option is to use a clever device that clamps the needle’s end to give you leverage as you pull it.

How do you raise a needle bar

If the needle on your sewing machine is not raised correctly, the machine will not be able to be threaded. To raise the needle, turn the handwheel toward you (counterclockwise) so that the mark on the wheel points up, or press the needle position button (if your machine is equipped with one) once or twice.

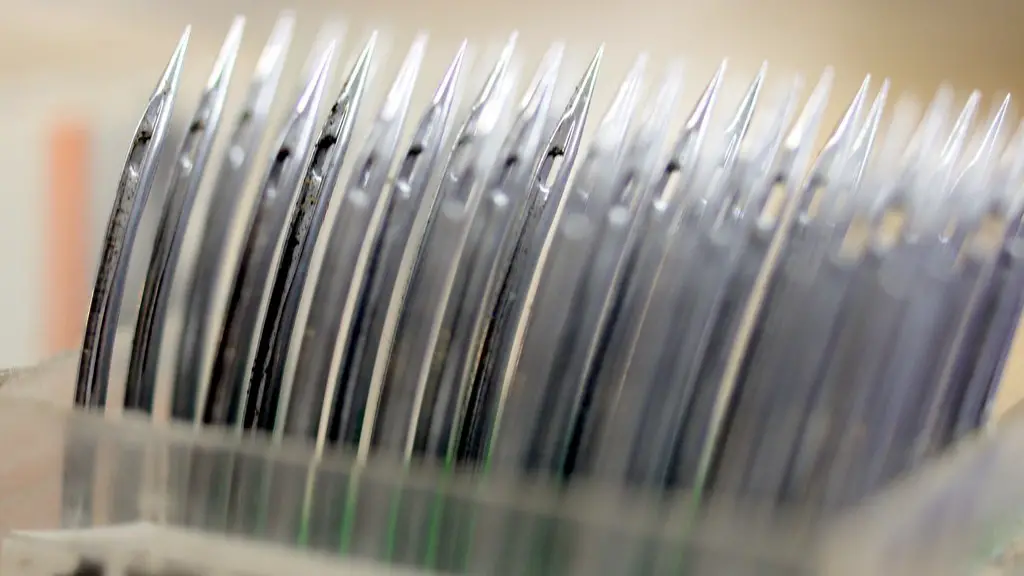

This is your needle board. So right over here that screw you see there, each machine has it. This is what holds your needle in place. You’ll notice that there’s a lot of different size screws, and that’s because each machine will have a different size needle that it uses. The smaller the screw, the smaller the needle. The larger the screw, the larger the needle.

How do you raise the needle on a sewing machine?

If the needle is not correctly raised, the sewing machine can not be threaded. Make sure to raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up. This will ensure that your machine is threaded correctly and can sew properly.

The needle position on a sewing machine can be adjusted by pressing the “+” or “-” keys on the stitch width keypad. This will move the needle either to the right or left. This is helpful when sewing straight stitches or triple stretch stitches.

How do you unfreeze a sewing machine

If your sewing machine is frozen, there are a few steps you can take to unfreeze it. First, turn off the machine. Then, take off the machine’s bobbin and bobbin case. Next, all machine covers should be taken off so you can check the machine’s interior. If you see any lubricant stains, purge the shuttle area. Finally, oil the machine and check the needle to make sure it is still in good condition.

Sewing is a great way to show your creative side, but it can be frustrating when things don’t go according to plan. Here are some common sewing problems and how to fix them:

Needle thread breakage: Check that your needle is the correct size and type for the thread and fabric you are using. If the needle is too small, it will break the thread. If the needle is too big, it will damage the fabric.

Bobbin or looper thread breakage: Make sure the bobbin is correctly threaded and that the tension is not too tight.

Thread fusing when the machine stops: This is usually caused by user error, such as sewing too slowly or incorrect needle placement.

Skipped stitches: Check the tension and needle size. If both are correct, try sewing a little slower.

Imbalanced / variable stitching: This can be caused by the needle being inserted at an angle, incorrect tension, or a dull needle.

Staggered stitching: This usually happens when the fabric is not fed evenly into the machine. Try using a fabric guide or feed dog Cover.

Variable stitch density: This is usually caused by incorrect tension.

Seam pucker

How do I reset the tension on my sewing machine?

The screw on the flat/closed side of the bobbin case is used to adjust the tension of the bobbin. Turning the screw a tiny bit counterclockwise will loosen the bobbin tension; turning it clockwise will tighten the tension.

If you think you have a bad belt, it’s best to replace it as soon as possible. A bad belt can cause your machine to struggle to sew or even stop sewing altogether. To avoid this, keep an eye out for signs of a bad belt, such as cracks, excessive slack, or disintegration.

Warp Up

There are a few possible reasons why your sewing machine needle won’t go up and down. One possibility is that the needle is not properly inserted into the needle bar. Another possibility is that the needle bar is not properly seated in the machine. Another possibility is that the tension on the needle is too tight. Another possibility is that the presser foot is not properly seated. Another possibility is that the feed dogs are not properly positioned. Another possibility is that the machine is not properly threaded.

This is a question that can be difficult to answer without seeing the sewing machine in question. There are a few potential reasons for why the needle might not be moving up and down as it should. First, it could be that the timing is off and needs to be adjusted. Another possibility is that the needle is not properly inserted in the sewing machine. Finally, it could be that the sewing machine is simply not working properly and needs to be repaired or replaced.