Are overlocker needles the same as sewing machine needles? Every sewing enthusiast knows the importance of having the right needles for the task at hand. But what’s the difference between needles for a traditional domestic sewing machine and its bigger, more industrial counterpart, the overlocker? Although it can be easy to assume both types of needles are the same due to their shared purpose, there are actually a few differences between them.

For starters, regular sewing needles are usually thinner and their points are sharper – designed for going through fabric – than their overlocker counterparts. Despite their differences, both types of needles are designed to cut into the fabric and make thread slits when pushed through, known as an ‘eyelet’. This eyelet is wide enough to fit the thread in, thus creating a stitch. Overlocker needles, however, often feature a thicker and more blunt point – built for thread causing little to no damage to the fabric when piercing through.

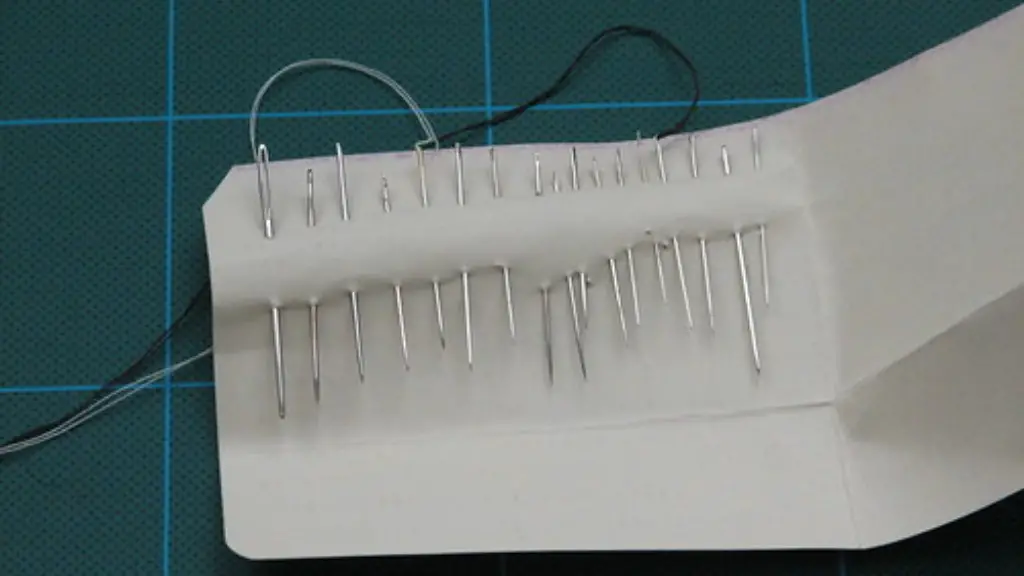

In addition, the shank of an overlocker needle is longer and the thread hole of an overlocker needle is located above the shaft. This allows the looper to wrap around the needle and pick up the thread before stitching. Furthermore, overlocker needles mostly come in sizes ranging from 80 to 120, and are primarily made of metal or plastic. Different models are available, ranging from regular to coated types as well as specialised ones for easy fabric coverings.

On the other hand, regular sewing needles come in sizes ranging from 8 to 16, and come in a wider range of materials, from metal to sturdy natural materials designed for thicker materials. Some specific types of needles include the universal needle, a general purpose needle, and the stretch needle, designed for elastic fabrics such as lycra.

Sewing pros often advocate for double-checking the needle types when it comes to sewing a specific type of material. This goes for both machines and overlockers, as having the right needle can prevent damage to the fabric, as well as help maintain the machine’s level of accuracy. Aside from that, they also advise changing needles as often as possible, as dull and blunt needles can eventually cause more damage over time than any worn fabric.

Types Of Overlocker Needles

When it comes to specific types of overlocker needles, there are many varieties that are suitable for various fabric, thread and stitching needs. All overlocker needles come with several types of sizes and shapes, such as those characterised by a large, thick neck and a round point. This type of needle is perfect for stitching fabrics with a pile such as velvet, quilt batting and fleece. On the other end, needles with a flat point feature a sharp, truncated edge and have a spear-like shape, allowing them to easily penetrate even the most tightly woven fabrics and deliver a professional finish.

Needles also come in a variety of types that can handle specific thread sizes, ranging from fine threads to coarse threads. For instance, a sewing enthusiast can use a size 16 needle with a fine thread for light-weight fabrics, or a 130 needle with a heavy thread for more robust items like jeans and denim shorts. In any case, it’s important to meticulously double-check the thread and needle specifications before choosing one.

On a related note, overlocker needles are also designed to work well with distinct types of fabrics. Depending on the thickness and nature of each fabric, the type of needle can be selected. If a fabric is delicate, for instance, a slowly tapered, easy-going flat needle is best as it sews better and prevents the fabric from being overpowered. On the contrary, an extremely sharp point or a chisel point will be better for sturdy fabrics.

When To Replace Overlocker Needles

A sewing pro may advise to replace overlocker needles every 2 to 5 hours of stitching, or whenever the thread starts to pull. It’s also important to switch needles when working with thicker fabrics and heavy threads. As fabric thickness and thread size vary, the needle should be changed accordingly. It is also worth mentioning that in some cases, an overlocker needle becomes slightly bent over time. Disregarding needle bends won’t only cause awkward stitching but can also affect the accuracy of the machine, something most domestic sewers take great care to avoid.

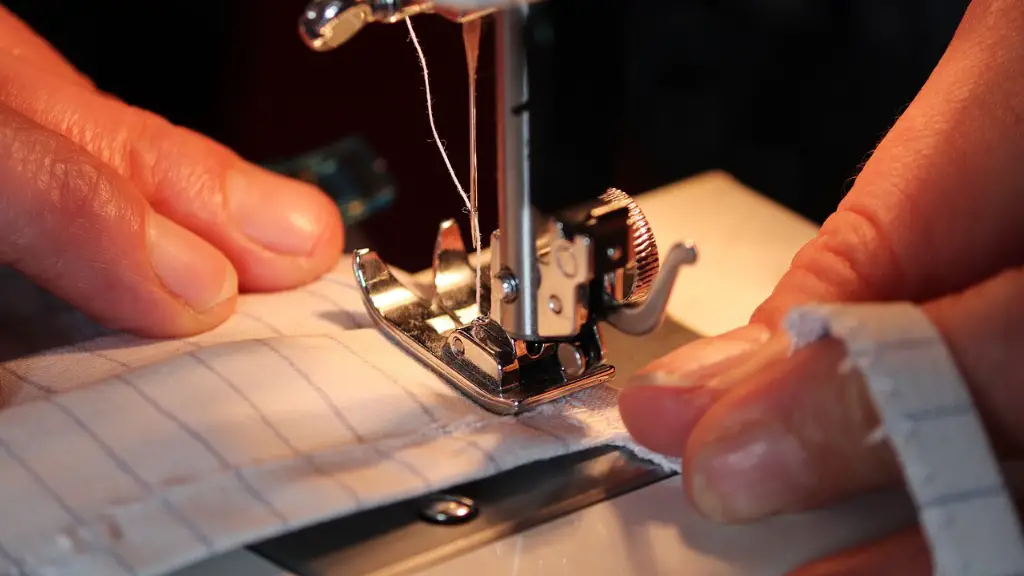

To change the needle, users must first unthread the machine and then turn the power off. They should then unscrew the needle plate, release the needle and fit the new one. It’s crucial to use the right size of needles to maintain the machine’s general working order. With its unique characteristics and suitable sizes, the right needle can make all the difference in the type of stitches produced. It can also help optimise the machine for a tremendous diversity of materials and threads.

Conclusion

To summarise, there are some differences between traditional sewing needles and overlocker needles. Although both types of needles are designed to cut into fabric and make thread slits, regular needles are thinner and come in sizes from 8 to 16. Overlocker needles, more suitable for industrial use, come in sizes from 80 to 120 and often feature a thicker and more blunt point. Various needle types exist for different thread sizes, fabrics and stitching needs. Additionally, it’s recommended to replace overlocker needles every 2 to 5 hours of stitching, or whenever the thread starts to pull.

Maintenance Of Sewing Machines

For optimal efficiency, sewing machines and overlockers need to be regularly serviced and professional maintenance is recommended at least once a year. That way, any thread buildups or dried oil can be removed and the machine can be sanitised and disinfected. An annual maintenance also includes a check of the thread tension, bobbin winder, machine needle, tension disc and drive belt, as well as all of the moving parts. Properly maintained machines also tend to last longer and run smoother, as well as provide more consistent finishes on every fabric.

In addition, lubrication is also a required step for any sewing machine. Sewing machine oil can be used for regular maintenance and should be applied all the time, especially for parts that move, such as the needle bar, feed dog and pulleys. This type of oil should never be used in overlockers, however, as it can cause severe damage. Overlocker oil, compatible with all types of threads, is the best option for regular oiling.

Ultimately, due to the delicate nature of the machine’s mechanics and the potential risks of damage, experts strongly advise against doing DIY maintenance or using improvised parts. Working with professionals or authorised technicians is always the best choice as they will have access to genuine parts, use relevant tools and are familiar with the different components that make up a sewing machine.

Useful Accessories For Sewing Machines

Apart from needles and threads, there’s a wide range of accessories available to make sewing easier. A foot pedal, for example, can help people get a better grip when working with a machine. The foot pedal is also perfect for anyone who frequently switches fabrics or threads, as it allows for quick auto-stop and start for more consistent stitches. Some extra accessories held in high regard by sewing professionals are scissors, thread racks, lint brushes, seam rippers, pincushions, bobbins and tweezers.

Scissors are ideal for cutting the thread when a sewing project is finished and thread racks are perfect for keeping all spools of thread in a neat, organised fashion within reach. Additionally, lint brushes work great for grabbing excess lint between stitches and a seam ripper is essential for unstitching simple projects. For easy storage when surrounded by needles and pins, a pincushion is the best bet. Finally, bobbins come in handy for essential tasks such as turning the fabric right side out and tweezers help in mending hems and removing threads.

Conclusion

To summarise, sewing machines and overlockers need to be regularly serviced to help maintain its level of efficiency. Cleaning and lubrication should be done on a regular basis and professional servicing is highly recommended for optimal results. Different types of overlocker needles are available for specific thread sizes, fabrics and stitching needs. Replacing the needle every 2 to 5 hours of stitching is also a nice habit to get into. Useful accessories such as foot pedals, scissors, thread racks, lint brushes, seam rippers, pincushions, bobbins and tweezers can also make the task much simpler and much more enjoyable.