Leather is one of the oldest and most sought-after fabrics in the world. Craftsmen have used this versatile material to make leather goods for centuries. Now, with advancements in technology and improved knowledge of leather, the demand for leather products has increased. There are a few considerations that must be taken into account when deciding if a special sewing machine is necessary for working with leather.

Before delving deeper into this question, it’s important to note that leather is much more difficult to work with than regular fabrics. It requires specialized tools, knowledge, and experience to produce top-notch results. That being said, some people may decide to proceed with a regular sewing machine for their leather-working projects.

The most straightforward approach is to purchase an industrial-grade sewing machine specifically designed for leather projects. These machines are specifically designed to handle the strain of stitching through thick and tough leathers with ease. They tend to be more expensive than regular models, but ultimately provide the performance to tackle difficult leather working projects.

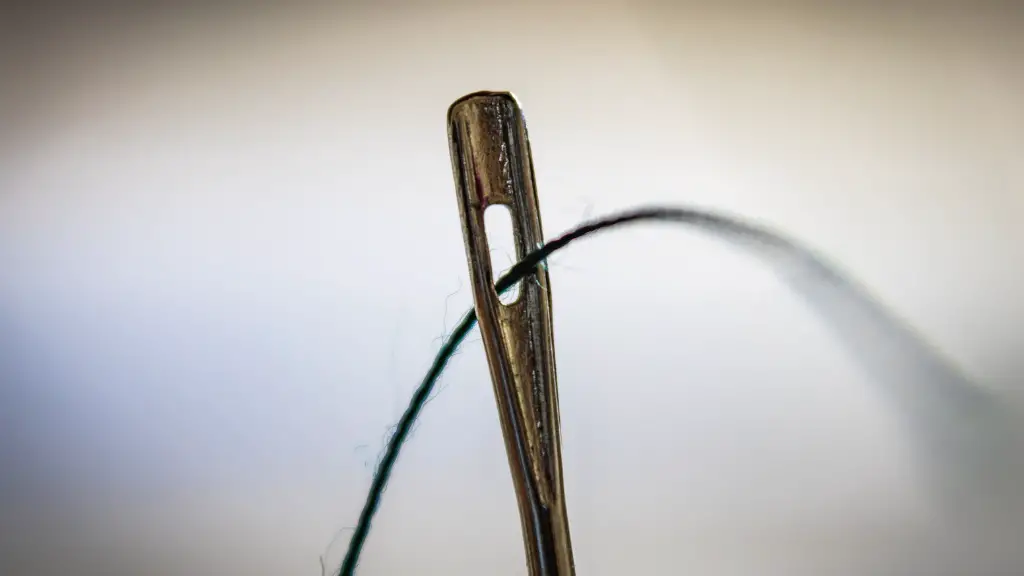

Alternatively, some experienced leather working hobbyists may be able to successfully take on small projects with a regular sewing machine. This involves shortening the stitch length and using specialized needle tips designed for leather. However, it’s important to note that this is a more technically challenging undertaking, as the machine may not be able to handle too much strain.

Finally, some hobbyists may be able to use an overlocker machine, which is a machine designed for heavier-weight fabrics and thicker leathers. If a leather worker possesses skill and the appropriate tools, they may be able to use an overlocker to create a professional-looking finish. However, it is important to keep in mind that using an overlocker to work with leather requires a great deal of care and precision.

Leather Quality

When it comes to leather, the quality and thickness of the material play a major role in determining whether a special sewing machine is needed or not. For thin and pliable leathers, a regular machine may suffice. But thicker varieties, such as Italian leather, will require a much more powerful machine in order to properly stitch through the material. Therefore, it’s important to keep an eye on the type of leather being used for a project.

Leather Working Projects

The type of project being undertaken is another important factor that needs to be taken into account. If the project is small and simple, such as a shoulder bag or a small wallet, then a regular sewing machine may be sufficient. But for more complex projects, such as custom jackets and purses, a heavy-duty machine specifically designed for leather may be the better choice.

In comparison to regular fabrics, leather is tougher and more labor intensive to work with. Essential factors, such as size and complexity of the project, should be evaluated before deciding on which type of machine is required. It is also important to consider the type and quality of the leather being used, since this determines the machine power and stitch length. In general, leather requires specialized tools and skill to produce top-notch results. Nevertheless, with the right knowledge and preparation, leather working projects can be completed to a professional standard with a great deal of care and attention.

Specialty Leather Threads

Some projects, such as purses and wallets, may necessitate the use of specialty leather threads. These are typically stronger and tougher than regular threads, ensuring that the finished product is durable and long-lasting. They tend to be available in a variety of thicknesses and colors, allowing the leather worker to customize the look of their leathergoods to suit their preferences.

There are a few different options available on the market for these specialty threads, and it’s important to evaluate the project requirements before choosing one. Some threads may be better suited for certain specific tasks, such as certain fabrics or leathers, or for certain stitch types, such as lock stitch. Therefore, it is essential to have a thorough understanding of the project requirements before choosing a thread.

Tools and Supplies

Along with a sewing machine and specialty threads, leather workers need to have the right tools and supplies in order to properly work with leather. It is important to have a steady supply of needles, bobbins, waxed threads, and leather punches, as these are essential for completing any leatherworking project. In addition, an awl is necessary for creating precise holes in the leather and a hammer is used to properly flatten and stretch leather.

It is also important to invest in leather-specific cutting tools, such as leather shears and leather punches. These tools help the leather worker make accurate cuts and precise holes, ensuring a clean and professional finish. Other important supplies include scissors, a cutting mat, rotary cutter, and straight edge ruler.

Finishing Touches

The finishing touches are also extremely important for leatherworking projects. A variety of conditioning and finishing products can be used to protect the leather from moisture, dirt, and other conditions that may damage the material. It is also important to have a good-quality leather sealant such as wax or oil in order to enhance the look of the leather. In addition, it is essential to properly care for the tools and supplies used in leatherworking, as this helps to maintain their longevity. For example, sharpening and oiling scissors and knives as needed can help to prevent damage and wear.

Leather Working Knowledge

Besides tools and supplies, it’s essential to have a good understanding of the craft of leatherworking. Understanding the basics, such as how to accurately measure and cut leather and how to properly stitch it, is essential for producing top-notch results. Additionally, knowledge of different leather types is also beneficial. Different varieties of leather have different working properties, such as different weights, thicknesses, and textures. Understanding these properties is helpful for selecting the appropriate materials and techniques for a project.

Conclusion

Whether or not a special sewing machine is needed for leatherworking projects depends on several factors, including project size and complexity, the type and quality of leather, and the leather worker’s knowledge. Spending time to understand the basics of leatherworking is essential to create quality products and achieve professional-looking results.