Preparation

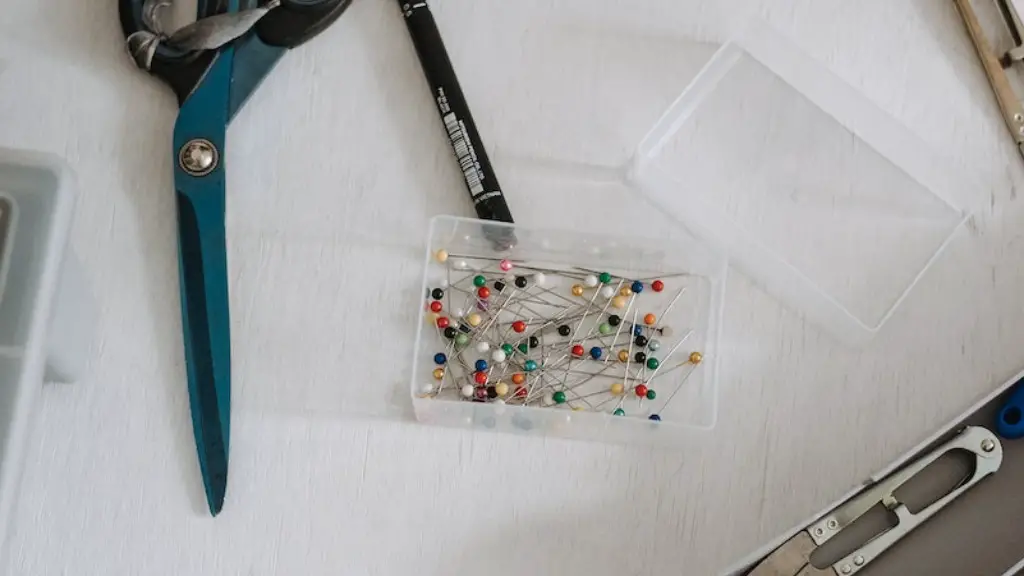

Before you start, it is important to make sure you have the appropriate materials and tools. You need a sewing machine and cabinet, screws, zip ties, foam tape, and a drill with appropriate drill bits. Make sure that you have all the necessary items; if any of the supporting materials are missing, the process may be difficult or impossible to complete.

Locating the Machine

Place the sewing machine in the cabinet to get a good idea of how the machine should fit in. Adjust the machine to the correct height and position, making sure to leave enough space around the machine itself. If the machine is too close to the walls of the cabinet, it will be impossible to properly attach it.

Attaching the Sewing Machine

Once you have determined the ideal location for the machine, you can begin the process of attaching it. Before you begin drilling any holes, use zip ties to firmly attach the machine to the cabinet. This will provide additional stability and prevent the machine from moving during the drilling process.

Drilling the Holes

Use the drill to make holes between the edge of the sewing machine and the cabinet to add additional stability. The holes should be located where the sewing machine and cabinet meet, and should be the right size for the screws you are using. Make sure the holes are drilled to the correct size and in the right places.

Inserting the Screws

After the holes have been drilled, you can now insert the screws. Make sure the screws are fitted tightly and securely, as they will be responsible for keeping the machine in place. Be careful not to overtighten the screws as this could cause damage to the machine or the cabinet itself.

Adding Foam Tape

To ensure maximum stability, you can attach foam tape between the edge of the machine and the cabinet. This is especially useful if the machine is in an environment with a lot of vibration. The tape will provide additional cushioning to keep the machine from moving around.

Testing and Troubleshooting

Once the machine is securely attached, it is important to make sure it is functioning properly. Connect the machine to the power source and test out its various functions to make sure it is working correctly. If anything seems to be wrong, check the connections and screws to make sure they are properly tightened.

Extending the Life of the Attachment

To make sure the attachment is as secure as possible for its lifetime, it is important to regularly check the screws and zipper ties for any loosening or wear. Additionally, make sure that the foam tape is still in good condition, and if not, replace it with new foam tape. With this regular maintenance, you can ensure the machine and the cabinet remain firmly attached for years to come.

Minimizing Vibration

Vibrations can be problematic for sewing machines and can cause it to become loose over time. To minimize vibrations, it is important to make sure the screw and zipper ties are always properly tightened and that the foam tape is in good condition. Additionally, it is important to know where the most vibrations are coming from and take extra care when attaching the machine in those areas.

Using Smaller Size Screws

For maximum stability, use screws that are slightly smaller than the holes they are being placed in. This allows the screw to avoid slipping and keeps the machine firmly attached to the cabinet. Be careful to avoid overtightening the screws and make sure they are always properly secured.

Optimizing the Position of the Machine

The position of the machine is key to ensuring it stays securely attached to the cabinet. Make sure that the machine is not too close to the walls of the cabinet and leave some space for the attachment. Additionally, make sure the screws are not placed in an area that can easily be reached by someone.

Adjusting the Height of the Machine

Properly adjusting the height of the sewing machine is important for both comfort and productivity. If a person who is using the machine is too cramped, they can easily end up with back pain and shoulder issues. On the other hand, making sure that the machine is in a comfortable spot allows the user to stitch more efficiently and improve the quality of the work being done.

Using the Correct Drill Bits

The right drill bits are important in the process of attaching the sewing machine. Make sure that the drill bits are the appropriate size and type for the materials you are drilling. Using the wrong drill bit can cause immense damage and put extra stress on the screws and cabinet itself.

Avoiding Damage to the Cabinet

To avoid damage to the cabinet, make sure that you are not using too many screws or drilling more holes than necessary. Too many screws can damage the cabinet and make it difficult to remove and reattach the machine in the future. Additionally, it is important to avoid drilling too close to wooden parts of the cabinet—make sure to leave enough space for the screws to be inserted without causing any damage.

Checking for Any Imperfections

Once the machine is securely attached to the cabinet, it is important to inspect the area around the attachment to make sure there are no imperfections. Make sure there are no screws sticking out or any other issues that could harm the user. If any issues are found, it is important to address them immediately in order to avoid any risks or discomfort.