Dreams of making beautiful garments, re-constructing heirlooms, and creating elaborate quilts can come true when equipped with the knowledge of how a sewing machine bobbin works. When a thread is properly wound onto the bobbin, a variety of stitching skills become available to the sewer. Keep reading to learn the basics of a sewing machine bobbin and how to use it so the creative journey can begin.

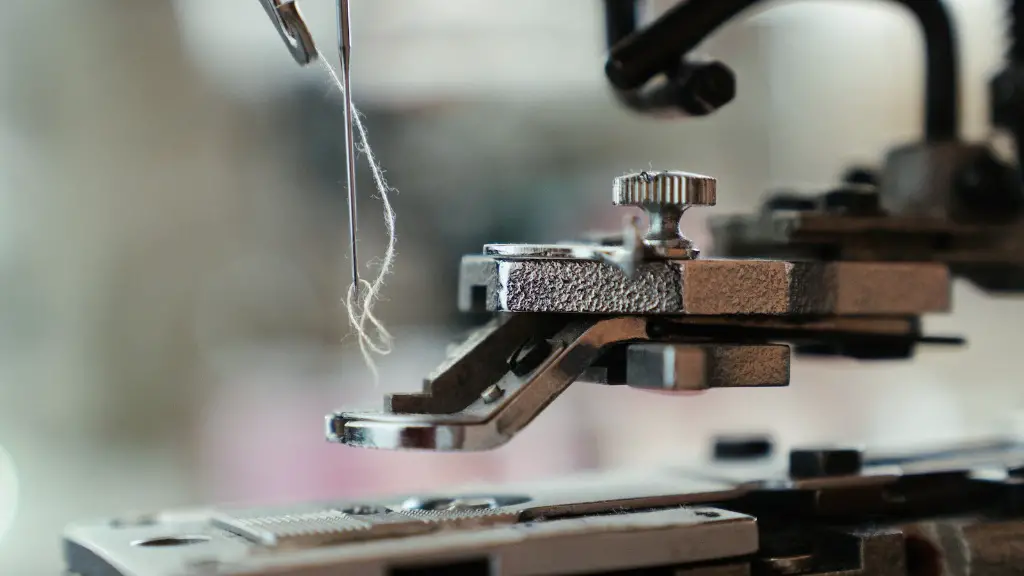

A bobbin is a small cylindrical spool that fits inside a sewing machine. The bobbin holds the thread for sewing onto the fabric. The needle passes through the bobbin case, forming a stitch by interlocking two strands of thread – the top thread which feeds through the needle and the bottom thread that comes from the bobbin.

Typically, the bobbin is inserted into the small cavity of the sewing machine, winding the thread in a clockwise or counterclockwise direction depending on the type of machine. The bobbin case holds and releases the thread in a particular manner, allowing for tension to be maintained between the two threads.

Bobbins are available in multiple materials, fiberglass and plastic being the most common. The plastic bobbins are designed to fit into specific brand-name machines and can only be used in those models. Fiberglass bobbins are universal, but are heavier than plastic.

Other types of bobbins include metal and ceramic packets. Metal bobbins are typically used in industrial sewing machines because of the longevity and resistance to wear and tear. Ceramic bobbins are made with ceramic material that allows for controlled thread tension.

In order to use a bobbin to its fullest capability, it must be wound with thread. Manufacturers often attach special thread guides that clamp onto the machine, allowing the spool of thread to feed through a decorative eyelet toward the bobbin. It’s imperative that the thread doesn’t overlap the edges of the bobbin as this causes tension problems.

To ensure the stitching of a project is smooth, bobbins should be wound to the correct tension. Bobbin tension is adjusted by turning a small screw located within the bobbin case, which tightens and loosens the needle thread.

Maintenance

In order for the bobbin to perform optimally, it is important to take good care of the machine and its components. Maintenance includes cleaning and lubrication, which prevents accumulation of dirt, thickening of grease, and rusting of parts.

Cleaning should be done after each project and the machine should be opened up, the bobbin case taken out and cleaned sufficiently. Over time, dirt and dust accumulate, thus it is important to blow out all the dust particles with pressurized air. Clogged bobbins can lead to thread breakage. Lubrication should then be applied to the bobbin casing in a thin layer using a lightly oiled cloth, as too much lubrication can ruin the casing.

To ensure best performance, battery-powered and electric machines should still be wound by hand, as machine-wound bobbins can cause the threads to become tangled and, in some cases, actually jam the machine.

Regularly replacing or rejuvenating the bobbins guarantees that they are in the best condition possible. This is especially important for elderly machines or machines that are rarely used. If a sewing machine has been laid idle for a long period of time, additional maintenance may be required.

Troubleshooting

Sometimes, even when the bobbin is wound correctly, the threads can still get tangled and cause uneven stitches. This is because the upper thread tension may be too tight, causing the needle to pull the bobbin thread from the top instead of from the bottom.

Incorrect thread tension can be compensated for by manually loosening the upper thread tension a bit and calibrating the bobbin tension to suit, as the upper and lower thread tensions have to be balanced for the stitches to be even.

Uneven stitches can also be caused by jammed bobbins. To prevent this, make sure the bobbins are compatible with the machine, properly wound, and inserted into the bobbin case correctly.

Another common problem is thread breakage. Aside from dirt or small particles stuck in the bobbin, thread breakage may also be caused by worn out needles. Worn needles do not have a sharp point, which causes them to pull the bobbin thread too tightly or disrupt the formation of even stitches. In these cases, replacing the needle is recommended.

Replogle Coverstitch

For those with investments into a more advanced machine, a Replogle Coverstitch may be required. This specialized bobbin is compatible with industrial sewing machines and allows for multiple layers to be sewn together at once. The Replogle Coverstitch is typically used for the hem of the fabric, such as on the sleeve-ends of a blouse.

It’s important to note that not all sewing machines are built to accommodate a Replogle Coverstitch. Therefore, before taking a plunge into learning the intricacies of such a technical system, check the compatibility of the machine. Machines that do not have a Replogle Coverstitch mechanism must be adjusted manually in order to be used.

The construction of the Replogle Coverstitch is unique in that two threads are used simultaneously to loop in two directions, creating a sturdy stitch.This stitch type is typically seen on ready-made garments and is used to secure a seam in two directions at once. The two threads used are a left thread and a right thread, allowing the seams to stretch along with the fabric.

Knowledge of Bobbin Types

Once a person has mastered the basics of a sewing machine’s bobbin, they may find themselves exploring specialty types. Black Bean bobbins, for starters, are a type of bobbin often used for basting and ‘invisible stitching’ for curved edges and tight corners. These bobbins have a wider bobbin case and shorter bobbin, which allows for the bands to be pulled tightly for a crisp finish.

Side load bobbins are designed for consistent bobbin thread tension and increased stability over the course of sewing. This is due to the wrapping mechanism of the bobbin, which is completely different from traditional bobbins. The threads are embedded within a coil which is wound around the bobbin, rather than around it.

Lastly, drop-in bobbins are the most unique of the types mentioned. Instead of wound-in thread, the bobbin is a frame filled with pre-wound thread and inserted into the machine without the need of hand winding. This type of bobbin is often used to reduce the complexity of threading the machine, allowing for quick and easy sewing.

Fundamentals of Bobbin Use

One of the primary functions of a sewing machine is to use thread to stitch together pieces of fabric. In order for the machine to function properly and create a high-quality stitch, the sewing machine bobbin must be used correctly. Having the proper knowledge of bobbins and maintenance is essential for success.

The thread should be wound onto the bobbin to the correct tension, and the case should be calibrated to suit. It is also important to replace the bobbins with some regularity and take extra care to clean and lubricate the bobbin case. Taking the time to properly manage the machine’s parts and components will guarantee an enjoyable and highly satisfactory sewing experience.

Advanced Bobbin Types

To guarantee an even stitch, many sewers search for bobbins made of glass, ceramic and metal. Glass bobbins are designed to facilitate correct thread tension and allow for thread to move freely through the bobbin case. Ceramic bobbins are best for heavier thread as they are able to withstand more tension. Ceramics also feature more consistent and longer-lasting thread tension.

Metal bobbins on the other hand may be used in industrial sewing equipment and guarantee a longer lifespan due to their hardiness and resistance to wear and tear. However, these bobbins are heavier than other materials, so they are not a suitable option for portable or electric machines.

An understanding of the fundamentals and advanced bobbin types will enable a person to make the best use of these small spools of thread and create a variety of projects with skill and expertise.

Troubleshooting Bobbins

Uneven stitches can be a common issue for those just beginning their sewing journey, as the upper and lower thread tensions must be balanced for proper stitching. Knowing the basics of bobbin insertion and winding is essential, as the threads may become tangled if the winding is off. Additionally, if the machine has been laying idle for a long time, additional maintenance may be required.

Sometimes, even when the bobbin is properly wound with the correct tension, thread breakage may still occur. Aside from dirt or particles being stuck in the bobbin, it could be worn out needles causing the breakage. Worn needles do not possess a sharp point, which will not make the precise incisions needed to pull the bobbin thread consistently.

If any of these issues arise, it’s important to take a step back and review the settings of the machine. If all else fails, take it to a professional to assess and make necessary adjustments.

Working With Fixables

The advent of fixables brings a great option to alternating a sewing machineBobbins with special diagnostics and adjustability can be programmed to reduce tension and are designed to provide hands-free thread control. These bobbins often feature in the newer models of high-end sewing machines.

Learning the ins and outs of bobbins is an essential part of the sewing experience. From the basics to the details of fixables, having a comprehensive understanding of this small, but essential tool, is essential for mastering the art of sewing.