A sewing machine needle is one of the most important components of a sewing machine, allowing a user to create neat, precise and professional-looking stitches. Its unique design and construction enable it to penetrate fabrics in order to stitch them together. There are several types of needles available for use in modern sewing machines. Each of these needles is constructed differently and has specific characteristics that make it suitable for a certain type of sewing project.

The basic anatomy of a needle consists of the eye, shank, scarf and point. The eye features a round hole through which the thread runs. The shank is the part of the needle that locates it inside the sewing machine. It is generally about the width of a finger and is designed to fit into the slot of a sewing machine’s needle bar. The scarf is an indentation pressed into the side of the shank, and its purpose is to help guide the needle as it sews. The point of the needle is the part that actually pierces the fabric when sewing.

Different types of needles have unique shapes and designs, which are best suited to certain fabrics and projects. For example, there are special denim needles that are designed to sew through thick and tough fabrics. Conversely, ballpoint needles are best suited for sewing through knit fabrics, as they have a rounded point that won’t snag the material. Other different types of needles include quilting needles, topstitching needles and hemstitching needles.

As well as the type of needle, it is also important to match the needle size to the fabric and thread type. Needles come in assorted sizes, ranging from 9 to 16 (the larger the number, the finer the size). The most common needle size for general sewing is size 11, which is suitable for a wide range of fabrics, including quilting cotton, jersey knits and light- to medium-weight wovens. For finer fabrics, such as silk or satin, a size 9 to 11 is recommended.

In order to achieve the best possible results, needle sizes should also be matched to the type of thread being used. Generally, finer needles are used for sewing with finer threads, such as lightweight cotton thread or polyester thread. Meanwhile, heavier needles can be used for heavier threads, such as upholstery or pre-wound bobbins.

Maintenance of the needles is also important. As the needle pierces the fabric, it wears away and eventually needs to be replaced. However, needles can last for quite a long time if looked after properly. Before each use, the needle should be inspected for any signs of wear or damage. It is also a good idea to use the same needle repeatedly on the same type of fabric, in order to achieve optimal results.

How the Needle Forms Stitches

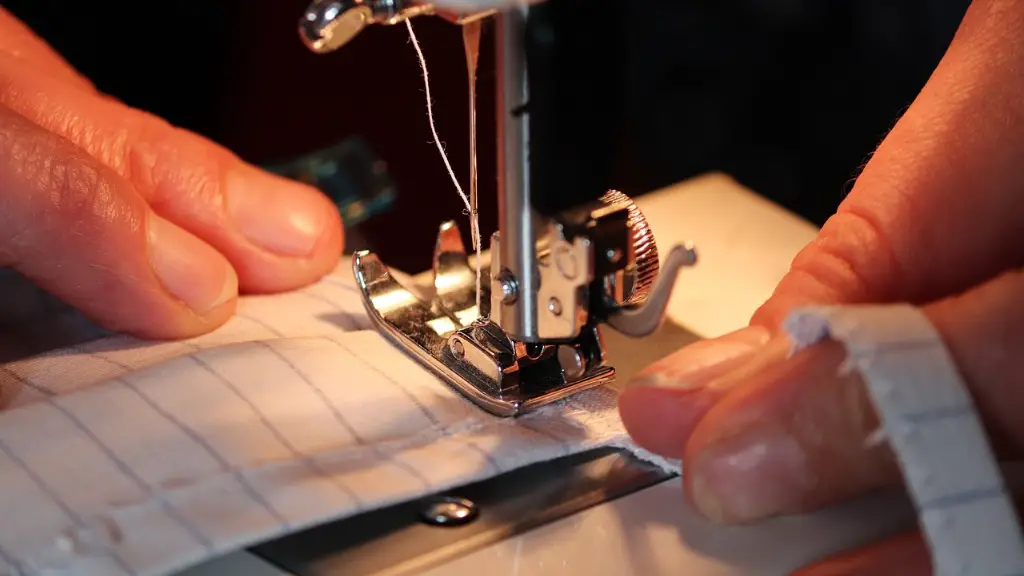

The needle’s point pierces the fabric when pushed down into it, while the thread is locked in place by the presser foot and the hook. As the needle rises back up, the hook rotates, catching the thread and looping it around the needle, creating the stitch. The movement of the needle then pushes the loop of thread over the presser foot, where it is held in place while the needle repeats this motion and creates the next loop. As these loops of thread form and pass over the presser foot, they interlock, creating the stitch.

The two main components that affect the quality of the stitches are the speed of the needle and the tension on the thread. The needle speed determines how many stitches can be formed in a certain amount of time, and the tension on the thread controls the consistency of the loops, ensuring that the stitches are all even and uniform in size. To adjust these settings, the operator needs to adjust the tension dial and the speed control dial on the sewing machine.

Although all sewing machines come with different settings and dials, they all work in the same way: the needle penetrates the fabric in order to form a stitch. It is important to select the right type of needle for the specific type of fabric being used and to adjust the needle speed and tension settings for the desired results.

Types of Sewing Machine Needles

Aside from the common needles used for general purpose sewing, there are several other types of needles designed for specialized applications. These needles are designed to be used with specific types of fabrics and can help create professional-looking results. Common types of specialized needles include:

- Shirt Stay Needles – These needles have a flattened point which helps to keep the material flat as the threads are stitched.

- Wing Needles – These needles have a flat point and a slightly curved edge which helps create a decorative ‘winged’ effect when sewing.

- Twin Needles – These needles feature two points and two eyes, which enable the user to stitch two rows of stitches in the same pass.

- Quilting Needles – These needles are designed to help reduce fabric fraying and provide smooth stitches for quilted materials.

Using the right type of needle for the fabric and project being undertaken is important, as this will ensure the best possible results. Additionally, needles should be inspected before each use and replaced when necessary.

Change the Needle Often

Regardless of the type needle being used, it is important to ensure that the needle is sharp and in good condition. Sewing machine needles become blunt and worn over time, which not only makes sewing more difficult but also affects the quality of the stitching. In general, needles should be changed after every 8 hours of usage. Additionally, needles should be discarded if they become bent, damaged or broken.

In addition to changing the needle regularly, it is also important to clean the sewing machine and the needle itself to remove any lint or thread residue. This helps to ensure that the needle can penetrate the material more easily. Cleaning the needle involves lightly brushing it off with a brush and then wiping it down with a clean cloth.

Essential for every Sewing Machine

Sewing machine needles come in a variety of shapes, sizes and designs, and each one is designed for a specific type of fabric and project. However, regardless of the type or size of the needle, it is essential for producing neat and professional-looking stitches. By selecting the correct type of needle and paying attention to its wear and tear, it is possible to achieve high-quality results with every sewing project.

Check if Needle is Compatible

Aside from the type of needle, it is important to make sure that the needle is also compatible with the sewing machine. Different sewing machines require different types of needles, and using the wrong type of needle can cause damage to the machine. Before replacing a needle, make sure to consult the user manual to ensure it is the correct type for the sewing machine.

Threading the Needle

Threading the needle correctly is also important in order to achieve the best possible results. First, the spool of thread should be loaded onto the machine and thread should be wound onto the bobbin. Once this is done, the thread should be inserted through the eye of the needle, which is usually located near the front of the needle. The thread should be pulled through from the front to the back, and the needle should then be secured in place.

Conclusion

Sewing machine needles come in a variety of sizes and designs, and the correct type of needle should be selected according to the type of fabric and project being undertaken. Needles should be changed regularly and inspected for any signs of damage. Additionally, the needle should be threaded correctly and the tension and speed of the needle adjusted in order to achieve the best possible results.