Have you ever wondered how much it costs to fix a broken or malfunctioning sewing machine? What about how to properly maintain them for longevity and cost saving? You’ve come to the right spot. We’re here to cover the necessary information that you should know to take care of your machine, and if something should go amiss, how much it might cost to repair it.

At its core, sewing machines are a tool just like any other. As such, a few important rules apply. In general, the better quality materials used in the construction of the machine, the better the parts will hold up over time. Better quality material also means that the machine won’t need repairs as often and if it does, the repairs are more simple and less costly. It’s typically in the best interest of the owner to buy a higher quality machine with fewer parts, as these machines are more robust and typically easier to repair.

For most sewing machines, the average cost of a repair service is anywhere between $30 and $100. Typical repair services can include cleaning, lubing and tension adjustment. In more serious cases, however, the repair service may involve parts replacement and repairs. The price of the parts can range from $5 to $100 depending on the severity of the problem. If the replacement part itself is not known, diagnostic rates may apply, translating to an additional $50 to $60.

These repair services can usually be performed by the store or shop where you purchased the machine. Many people prefer this option as there is often a warranty on their services, along with a technician that knows their machines. You may also be able to find a local sewing machine specialist in your area, if you live in a populated area, but it may not always be possible. Some people choose to do their own repairs if the parts are readily accessible and can be diagnosed by visual inspection.

In some cases, it may be best to throw in the towel and buy a new sewing machine. The economy of repair versus replace is an important factor in decision making. Generally speaking, if the cost of the repair is more than half of the cost of a new machine, then purchasing a new machine is the better economic choice in the long term.

To avoid these repair costs, proper maintenance of your machine is essential. This includes regular oiling, cleaning the bobbin case and changing the needle. Additionally, the manufacturer’s manual should be consulted on how to properly care for the machine. Follow the instructions and you’ll get several years of longevity from your sewing machine.

Maintenance of a Sewing Machine

Sewing machines require regular maintenance in order to function properly and avoid costly repairs. Depending on the frequency of use, some machines may need more frequent care than others. One of the most basic maintenance tasks is ensuring that the machine stays properly lubricated. All machines need to be oiled regularly in order to keep their parts moving smoothly and not get gummed up with dried lubricant. The owner’s manual should have instructions on how frequently the machine should be oiled as well as where to properly add oil.

The bobbin case is another important part of the machine that needs to be periodically inspected and cleaned. Proper functioning of this part can help avoid skipped stitches and tension problems. Regularly cleaning the bobbin area of any residue and dust is essential to maintain the accuracy of the sewing machine. This can be done by removing the bobbin case, often referred to as a bobbin shuttle, and cleaning it with a cloth or a blast of air.

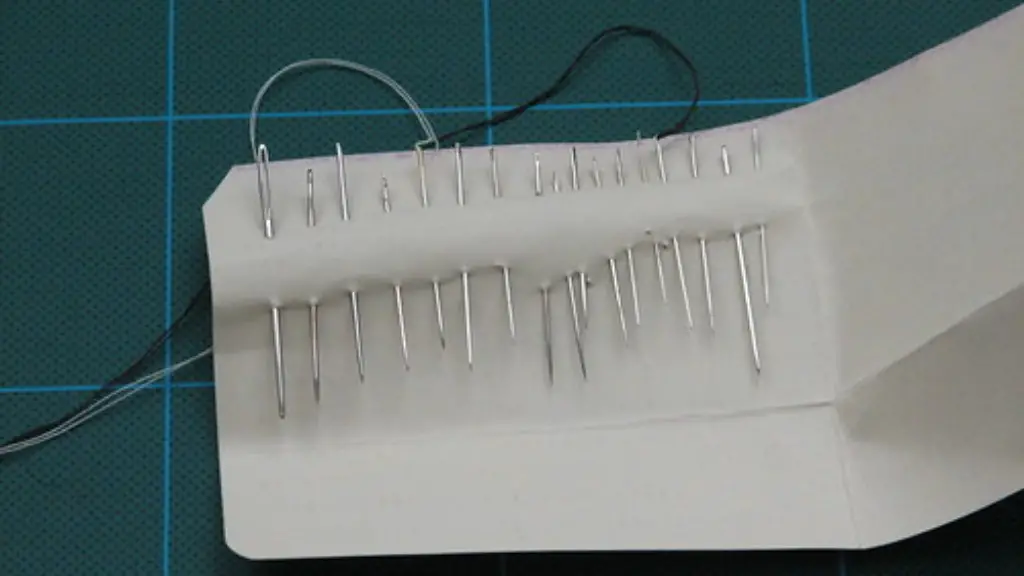

One of the most important factors in a sewing machine’s life is how often its needle is changed. They too wear out and can become dull over time, causing problems like skipped stitches. That’s why it’s important to use the correct size needle for the fabric you’re working with, as too small of a needle will increase the friction and wear of the needle. Additionally they should also be changed every 15-18 hours of sewing use.

Storing a machine properly is also a component of proper maintenance. Covering the machine and storing it in a dirt-free and dry environment is a must. Moisture and dust are enemies of sewing machines, so keeping the machine away from windows or other places with a large potential for these is essential. Additionally, temperature and humidity should be optimized in order to prevent rust.

Cost of Whole Machine Repairs

If all of the above fails and the sewing machine requires whole repairs, then the cost can range from $70 up to $200 for labor alone. If the machine is older or has complex designs, then the labor cost can exponentially increase. As far as parts go, the cost of new parts to replace the defective one, can range anywhere from $10 to $200 depending on the part needed and the availability of it.

For more serious repairs such as motor or wiring problems, the cost can range from $100 to $300 depending on the severity of the repair. It’s important to note that some of these types of repairs can become exponentially more expensive with the age of the machine, as certain components are difficult to acquire on older models.

Before committing to spending money on more serious repairs, it can be beneficially to communicate with your nearest sewing machine shop. It’s likely that they have experience with whatever problem you’re encountering, and may be able to suggest a cost effective solution or direct you to someone that can provide you with the repair you need at a reasonable price.

Replacement or Reconditioned Sewing Machines

In some cases it may be a better option to purchase a replacement machine instead of going through the process of repairing a malfunctioning one. In that case, the cost can range from $200 to $1000 for a basic model to $700 to $4000 for upper end models. If you’re in the market for a more professional model, they can range up to $6000 to $25000.

For those on a budget, however, there are other options like buying a reconditioned or refurbished machine. These machines are typically pre-owned models that have been reworked, tested and inspected. The price of these machines depend on the brand, condition and availability, and the discounts can range anywhere from 20 to 40%.

The IHSMarkit survey of sewing machine technicians estimates that up to 80% of people that can’t find a worthy technical shop for a repair will opt for a purchase of a new model. This isn’t surprising, as not everyone has access to competent technicians, and if the cost of the repair is too far out of line it can be difficult to justify taking the risk.

Conclusion

When it comes down to it, no two sewing machine repair experiences are the same. The location and experience of the technician and the brand, model and condition of the sewing machine itself all play a role in determining the cost of the repair. Ultimately, the best way to save money on repair costs is to properly maintain your machine and have a trusted mechanic on hand if repairs are needed.