What is Servicing of a Sewing Machine?

Servicing of a sewing machine involves periodic maintenance and inspections to keep it in top condition and prevent issues such as slipping stitches and uneven tension. Such services are usually done once or twice a year and involve dismantling, cleaning, oiling and adjusting each of the components to restore the machine’s original performance. By servicing the machine regularly, it will remain lively and last longer.

The Benefits of Servicing a Sewing Machine

Servicing a sewing machine helps to ensure that all parts are in excellent condition. By staying on top of servicing, you can fix minor issues before they become bigger ones that could potentially damage or destroy the machine. It also helps extend the life of the machine because well-maintained sewing machines run smoother and quieter than those that are neglected. Regular cleaning and oiling help to reduce the build-up of dust, lint, and other debris which can reduce the machine’s performance.

How Much Does Servicing a Sewing Machine Cost?

The cost of servicing a sewing machine will be greatly dependent on the brand, model, and size of the machine. The rate can range from $30-$150 and can take at least an hour of labor time. It also depends on where you take your machine for servicing; it is recommended to take it to a qualified sewing machine repair shop or to the manufacturer’s service site. Prices for spare parts and supplies will also vary depending on what type of servicing is done; the rate could range from a few dollars to hundreds of dollars.

Testing the Machine After Servicing

Before you leave the machine with a technician to be serviced, they will usually ask you to run some tests to make sure all the parts are properly installed and set up. You may be asked to test stitch quality, tension, and timing, as well as inspect the thread guides and cutting blades. Once the machine has been serviced, it is also important to test it again to make sure everything is running smoothly before using it.

Tips for Maintaining a Sewing Machine

Even after you have had your machine serviced, there are still some things you need to do to maintain it. The most important thing is to regularly clean and oil the machine. This should be done at least once a month, as it helps to lubricate the parts and reduce the chances of the machine malfunctioning. Keep the machine area clean and dust-free, as dirt can be a major cause of sewing machine breakdowns. Make sure to read the instructions and store the manual in a safe place to refer to in case of any issues.

Troubleshooting a Sewing Machine

If your machine isn’t working properly, the first thing you should do is to refer to the sewing machine manual. It should include instructions on how to troubleshoot the most common issues such as thread tension and stitch patterns. You can also use online resources such as instructional videos and tutorials to help you understand and learn how to service your machine. If all else fails, it is best to take your machine to a qualified professional who can help you diagnose and repair it.

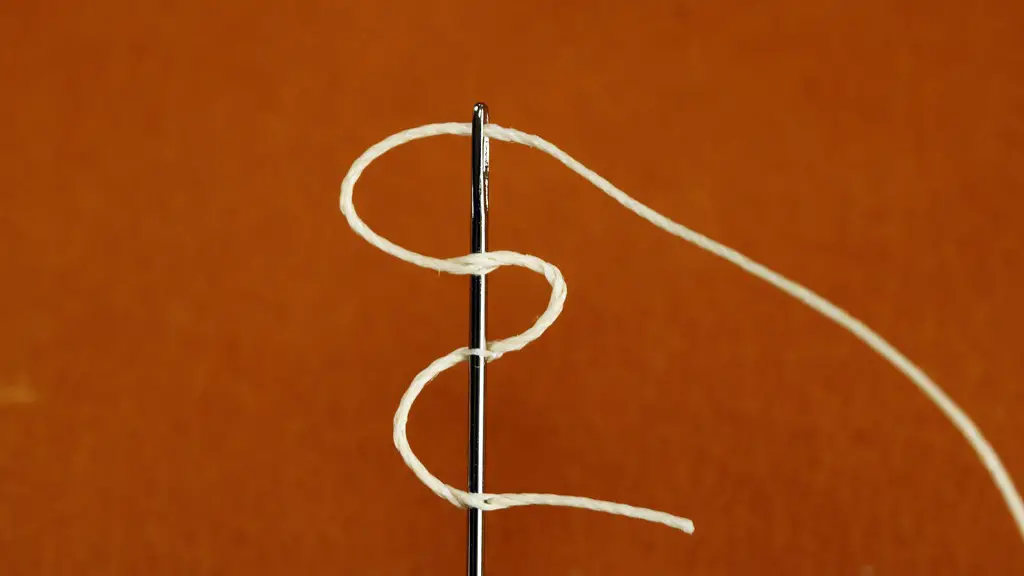

Keeping Sewing Machine Needles Clean

It is important to keep the needles clean, as dirty needles can cause skipped stitches, tension issues, and thread breakage. To clean them, you can use alcohol wipes or a lint roller, both of which can be purchased from the store. If the needles are too dirty, you can soak them in white vinegar for a few minutes before wiping them with a soft cloth. Make sure to clean the needle after each use, as this will ensure optimum performance from your machine and reduce wear and tear.

Storing a Sewing Machine Correctly

When you are done using your machine, make sure to store it correctly. It should be placed in an area that is not too humid or exposed to direct sunlight, as these can cause damage to the motor and other components. Additionally, make sure to unplug the machine and cover it with a clean cloth or dust cover when it is not in use. This will help to protect it from dust, dirt, and other debris which can cause clogging and damage.

Choosing the Right Sewing Machine Oil

Oil is essential for maintaining a sewing machine, as it helps to reduce friction, lubricate the components, and prevent wear and tear. It is important to choose the right kind of oil for your machine, as some oils can cause damage to certain components. Refer to the instructions manual for instructions on what type of oil should be used. Choose a high-quality oil such as mineral oil or lighter fluid to lubricate your machine; these are less likely to cause damage.

Checking the Accuracy of Sewing Machine Presser Feet

The presser foot of a sewing machine is one of the main components that helps to keep the fabric in place as it is being sewed. It is important to check the presser foot of the machine regularly to make sure it is working properly. If it isn’t, then it can lead to uneven stitching or misshaped seams. To check the accuracy of the presser foot, use a ruler to measure the distance from the fabric to the needle; the measurement should be the same on both sides.

Replacing Worn Out Bobbins and Needles

Over time, needles and bobbins can become worn and should be replaced. Bobbins should be checked periodically for cracks or chips, as these can cause tension issues or breakage. Needles should also be replaced whenever they become dull or bent, as this can also cause misalignment and damage to the fabric being sewn. It is important to choose the correct type of needle and bobbin for the type of fabric you are using, as this will ensure that your machine runs smoothly and the stitches are even.

Replacing Sewing Machine Belts and Motors

When a sewing machine belt or motor becomes worn, it can cause the machine to malfunction or even stop working. It is important to check the condition of the belt and motor regularly, as this will help to avoid any unexpected breakdowns. If you notice any signs of wear, it is best to replace them as soon as possible; this will ensure the machine runs smoothly and efficiently. Be sure to choose the correct belt and motor for your specific sewing machine model for optimum performance.