General Considerations

Oil is essential for the proper functioning of any mechanical device. When it comes to Janome sewing machines in particular, oil ports, which are located in various places around the machine, must be lubricated regularly. The amount of oil recommended for Janome machines and how often it needs to be loaded depend on the type, model and usage of the machine.

If a machine is being used frequently, then it may need to be oiled as often as twice a month. In cases where the machine is used less frequently, then the suggested oiling schedule could be cut down to once every three months. To ensure that the machine runs properly and to keep it in good condition, an oiling schedule needs to be established.

It is important to use the correct type and grade of oil for the Janome sewing machine. A high-quality oil containing petroleum additives is the best choice for a Janome machine. The grade of the oil depends on the type of machine and the temperature range where it operates. All manufacturers provide specific instructions on the type and grade of oil to use with their machines. It is highly recommended that these instructions be followed.

Overall, Janome machines require less maintenance than most other brands. Depending on the amount of use, regular oiling of the machine every two months or so should be sufficient to keep it functioning optimally. The specifics of the oiling process and type of oil used, can be found in the manual for the Janome machine.

Checking Machine Components

Before oiling the Janome sewing machine, the user should inspect it for signs of wear and tear. The user should check for loose screws, worn out thread guides, frayed cables and other loose components. If any part of the machine is not functioning properly, it should be checked and repaired before oiling. Oil can make such issues worse if applied to a malfunctioning machine.

Next, it is important to check the oil ports. Some machines have a dedicated oil port, while others have oil ports located in somewhat hidden spots. It is best to refer to the machine’s manual to locate the exact position of oil ports. If a machine has only one port, it should be oiled every two months. If a machine has more than one port, the instructions in the manual should be followed.

Another important point to keep in mind is to never add too much oil. Adding too much oil can create blockages and even seep into the gearbox, causing damage to the lubrication system. Too much oil can also cause the machine to malfunction, even after the oil is removed from the gearbox. The recommended amount of oil stated in the manual should not be exceeded.

In general, it is recommended to follow the oiling schedule in the user’s manual for the specific Janome sewing machine. This will ensure that the machine is properly maintained and the best results can be achieved.

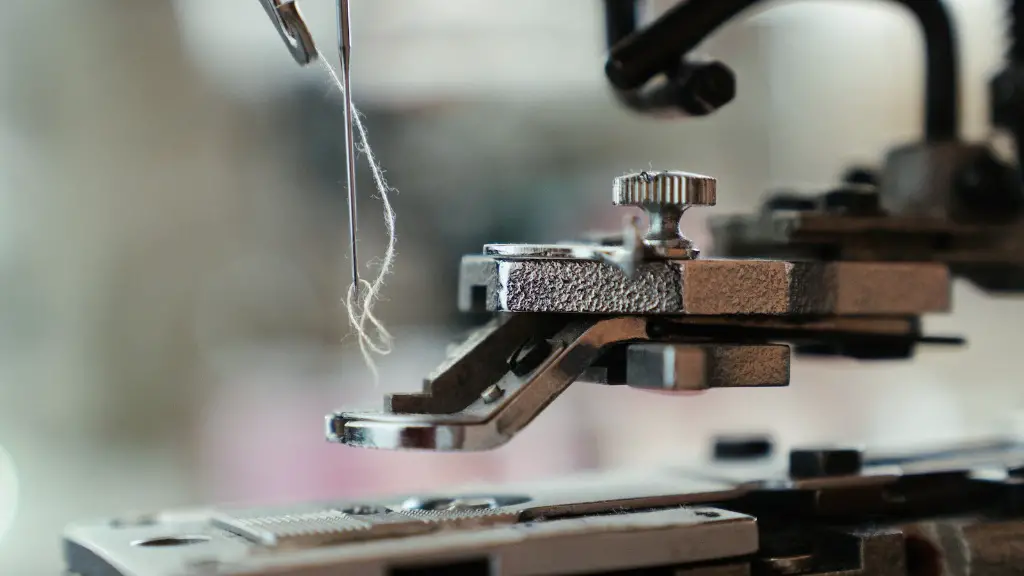

How to Apply Oil

Once the user has located the oil ports, the machine should be turned off and unplugged. Small brushes or calibrated syringes can be used to apply the oil into the port. It is also important to ensure that the machine is clean and no dirt or dust particles are present in the area before oiling.

Once the oil has been applied, the machine should be started and run for several minutes. This will ensure that the oil is well circulated throughout the machine and reaches all its parts. After that, the oil can be wiped off using a clean, lint-free cloth.

The user should also pay attention to any signs of friction or wear and tear that occur during the oiling process. If any issues are noticed, the machine should be serviced by a qualified technician as soon as possible.

Finally, the oiling process should be repeated regularly to ensure that the machine continues to function well and provides the best performance.

Cleaning the Machine

It is also important to keep the Janome sewing machine clean at all times. This will help to prevent dirt and dust build up and ensure that the machine remains in good condition. A damp cloth can be used to wipe down the machine and the parts each time it is used. If the machine is used very frequently, then it should be cleaned once a week.

Regular cleaning will ensure that the machine’s needle, stitch plates and presser feet remain dust-free and ready for use for every project. Additionally, all the parts of the machine should be inspected for signs of wear and tear and any malfunctioning parts should be replaced immediately.

Most Janome machines come with a cleaning kit that includes brushes and other tools. This kit can be used to clean the machine’s different parts, including the bobbin area, the needle, the threads and the inside of the machine.

The machine’s manual should be consulted to understand the cleaning and maintenance process more thoroughly. This will ensure that the machine operates optimally and any potential problems can be avoided.

Storage and Care

In order to ensure that the Janome sewing machine lasts for years, it needs to be properly stored and cared for. Storing the machine in a dry, dust-free area is essential. If the machine is going to be stored for an extended period of time, it should be cleaned and oiled before storing to prevent dust build up.

All loose components, such as the needle, thread, spool holder and presser feet should be stored separately in an appropriate container. This will ensure that they don’t get misplaced and lost and can be easily located when needed.

It is also important to make sure that the machine’s power cord and foot pedal are safely stored away to prevent any damage. Additionally, the machine should never be exposed to direct sunlight or rain. This will ensure that the machine remains free from dust, moisture and other damaging elements.

Overall, regular oiling and cleaning of the machine and general care of the machine’s components is essential to keep it in top condition.

Troubleshooting and Maintenance

If any issues arise with the machine, it is best to troubleshoot the problem and fix it as soon as possible. Small problems can often become bigger issues if not tended to early on. Therefore it is important to regularly inspect and maintain the machine to ensure that it operates smoothly for years.

If any issue arises, the machine’s manual should be consulted. Most manuals will provide instructions on how to troubleshoot the issue and provide instructions on the required maintenance. If a more complicated issue arises, the machine should be taken to a qualified technician for further inspection and repair.

Regular maintenance is essential to ensure that the machine keeps functioning properly. The user should also keep a log of maintenance and repairs so that they can easily refer back to it in the future. This will help to keep track of when the machine was last serviced and what kind of service it needed.

Finally, Janome sewing machines come with a guarantee. This guarantee can be used for repairs or maintenance for any issue that arises during the validity period. Consulting the guarantee can help the user to save time and money in case of any repairs or maintenance.