Steps for Adjusting Bottom Tension on Singer Sewing Machine

Knowing how to adjust bottom tension on a Singer sewing machine is essential for experienced sewers and budding hobbyists alike. Proper bottom tension ensures better stitch quality and fewer thread jams. This guide will walk you through the entire process, step-by-step.

Overview of Thread Tension

Thread tension is a delicate balancing act between the upper and lower thread. When the upper and lower tensions are correctly balanced, the upper thread is properly encased within the two threads, creating a nice even stitch. If the tensions are too loose, the stitches won’t be as secure, and if the tensions are too tight, fabric puckers and bunches. To prevent these issues, experts recommend adjusting the bottom tension first.

How to Adjust Bottom Tension on Singer Sewing Machine

1. Start by preparing the machine. Make sure the Singer sewing machine is unplugged, then remove any fabric or thread. Wind a new bobbin or adjust the tension on the existing bobbin if necessary by turning the bobbin tension dial.

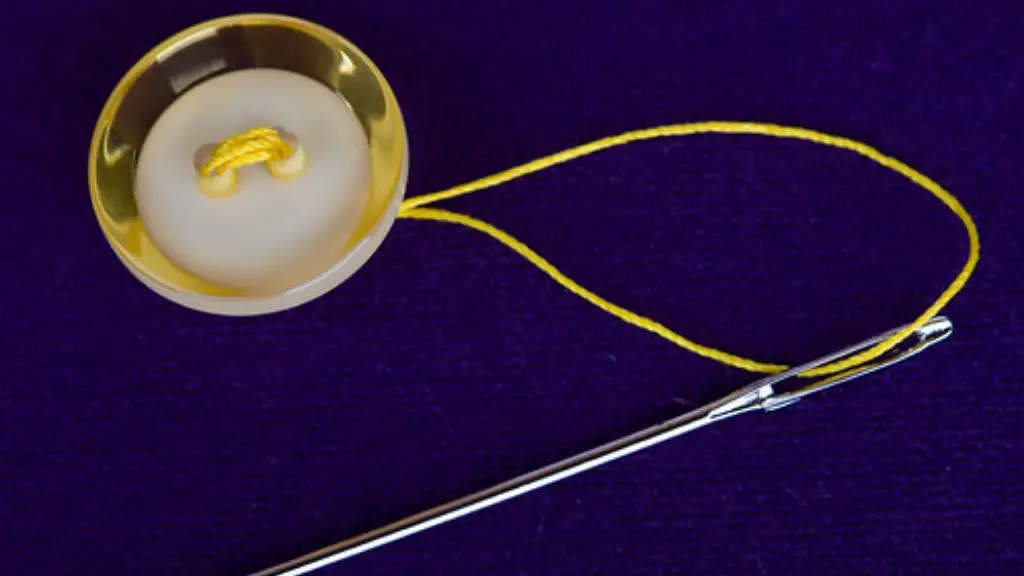

2. Now insert the bobbin into its case with the thread going in a clockwise direction. Put this near the needle with the thread going around the take up lever. Align the thread guide with the bobbin thread, and pull the upper thread to guide it under the presser foot.

3. Pull the bobbin thread from the needle plate hole and hold it between two fingers. Turn the tension dial on the left side of the Singer sewing machine until the bobbin and upper threads just barely release from your fingers. This indicates the tension is balanced.

4. Finally, try a sample seam on scrap fabric. If there is an issue with tight upper and loose lower thread, increase the bottom tension slightly. If the lower thread is too tight or the upper thread is too loose, reduce the bottom tension accordingly.

Tips for Perfect Thread Tension

1. Keep in mind that thread thickness plays a role. Finer threads usually require less tension, while thicker threads may require a higher tension. If you are able to avoid drastic changes in thread weight, then the bobbin tension dial should remain unchanged.

2. Check the upper thread tension setting and make any adjustments as needed. A good rule of thumb is that the upper tension should be set just slightly above the middle of its range. Since this varies between machines, check the user manual for the ideal setting.

3. If you’re still having tension issues, try changing the needle. For general purposes, a universal needle should work. But if you’re sewing something a bit heavier, like denim, switch to a size 16 needle instead.

4. When in doubt, always use a new bobbin. Bobbins wear out over time, so replacing them once in a while is important to maintain tension and stitch quality. Additionally, it never hurts to double-check the bobbin instructions before starting a new project.

Preventing Thread Breakage & Skipping Stitches

1. Threading issues stemming from worn or bent needles are a common cause of thread breakage and skipping stitches with Singer sewing machines. If the needle is bent or dull, replace it before adjusting the bottom tension.

2. Both the upper and lower tension is fine-tuned before starting your project. However, if you are suddenly experiencing tension problems, try increasing the sewing speed. This sometimes helps fix tension issues when all else fails.

3. If there is any build-up of lint or debris on the machine, be sure to clean it off. This can throw off mechanism and cause more tension issues.

4. Finally, check the upper thread for knots or tangles, as this can also cause skipped stitches or thread breakage. It’s best to inspect the thread spool before beginning the project, just to rule out any issues.

Thread Tension Troubleshooting

1. If the stitch still looks uneven after adjusting the thread tensions, check the fabric being used. Certain fabrics can put extra strain on the Singer sewing machine, making it difficult to create an even stitch. Try using a fabric stabilizer or adjusting the needle as needed.

2. If the samples still aren’t looking quite right, try switching the reed and presser foot combination. For knit fabrics, use the lightweight reed and smaller presser foot. For heavier materials, the larger reed and presser foot will create better tension.

3. If you consistently find tension issues, double check the settings on the tension disk. Rotate the disk one more click in either direction and try again. This should fix any remaining tension discrepancies.

4. If the problem persists, contact a professional technician to look into the problem. Broken or worn-out parts may need to be replaced. Depending on the model of your Singer sewing machine, parts may be available through your local sewing store.

Conclusion – Adjusting Bottom Tension

Adjusting bottom tension on Singer sewing machines is an essential part of the sewing process. Not only will it ensure the fabric doesn’t bunch or pucker, but it can also prevent skipped stitches and thread jams. By following the tips outlined in this guide, you should be able to create even stitches and enjoy professional results each and every time.