If your sewing machine needle is not in the correct position, your stitching will be off. You can easily adjust the needle position on most sewing machines.

To adjust the sewing machine needle position, first locate the adjustment screw near the needle. Then, using a small screwdriver, turn the screw until the needle is in the desired position.

How do you adjust the needle position on a Singer sewing machine?

As you move the slider up to five, notice how the picture changes and the dot is now in the middle of the screen. This is because the slider is now set to the highest setting, which means that the picture will be zoomed in more.

If you’re sewing machine needle is hitting the needle plate, it’s possible you have the wrong needle plate on the machine for the stitch you’re trying to sew. If everything else is in order – needle plate correct, etc. – and the needle is still striking the needle plate, you’ll need to take it to the dealer to be fixed, as something is out of alignment.

Why isn’t my needle centered on my sewing machine

The position of the needle on a Featherweight sewing machine is determined by the size of the needle itself. For example, a smaller size needle will sit on the left side of the needle hole in the throat plate, but a larger needle will be more centered. This is normal, as there is no adjustment on the Featherweight for the position of the needle.

The needle position can be changed from left to right by adjusting the stitch width dial. To set your needle in the right position, set your stitch width dial to 0. To set your needle in the left position, set your stitch width dial to 5. For normal center position, set your stitch width dial to 3.

What does needle clip position do?

The needle clip is used to adjust the fuel delivery on carbureted engines. The top position is the leanest because the needle is sitting farther down the inside of the tube, restricting the fuel flow. The bottom position is the richest because the needle is sitting closer to the bottom of the tube, allowing more fuel to flow.

The needle position can be changed by pressing the plus (+) side of the stitch width adjustment key moves the needle to the right Pressing the minus (-) side of the stitch width adjustment key moves the needle to the left.

How do you stop a needle from hitting a plate?

If you’re having trouble with your needle hitting the presser foot or needle plate, there are a few things you can check. First, make sure you’re using the right presser foot for the type of stitch you want to sew. Second, check that the needle isn’t bent, and if it is, replace it. Finally, make sure the needle plate is properly installed.

The needle on your sewing machine is not fitted properly. The needle clamp screw is loose. Firmly tighten the needle set screw.

How do you lift a needle plate

To remove the needle plate cover on a sewing machine, insert the tip of the index finger of the left hand into the notch at the back of the cover. Place the thumb of the left hand at the front of the needle plate cover and slide it toward you.

If you are having issues with your sewing machine needle bending or breaking, there are a few possible causes. First, check to see if you are pulling the fabric through too forcefully – this can cause the needle to bend or break. Second, check to see if the timing is out on your machine – if the timing is off, it can cause the needle to hit the bobbin case and snap. Finally, if all else fails, it is possible that the machine itself is jammed or damaged – in this case, it is best to take it to a professional for service.

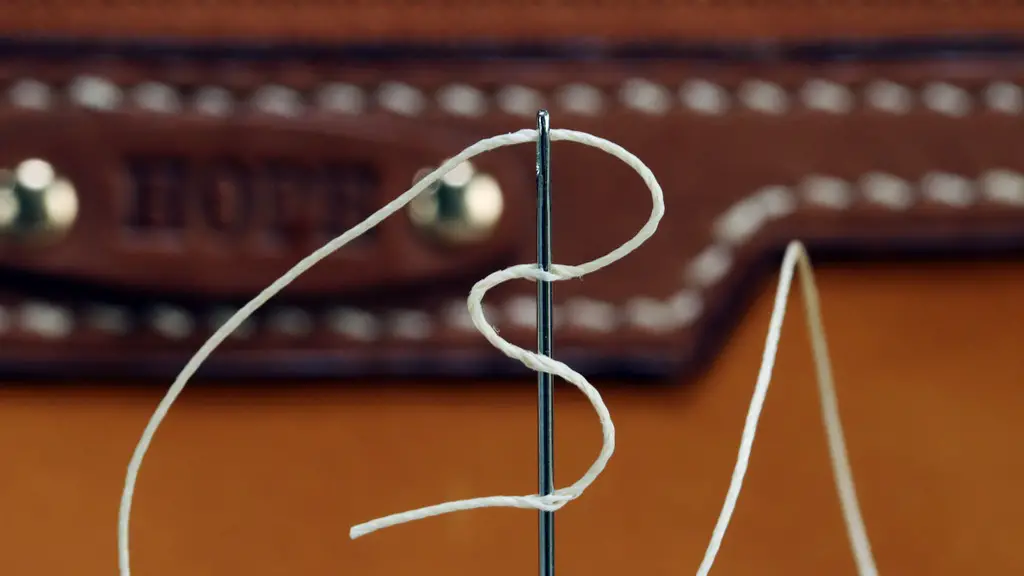

How do you set up a sewing needle?

Tying a knot in your thread is not always necessary in order to keep your stitching secure. If you are using a single thread, you can simply make a small stitch near the point where you inserted the needle and then create a little loop. Pull the thread tight and it will form a knot close to the fabric.

If you’re having trouble with your sewing machine, there are a few things you can try to fix the problem. First, try a new bobbin case. Make sure the shaft of the needle is towards the back, and use air to blow out any debris from the area where the needle is placed. Next, check to see if the needle is all the way up. Make sure the little screw is tight, and that the bobbin turns clockwise when you pull the thread. Finally, check the top tension to make sure it isn’t too tight.

How do you calibrate a Brother sewing machine

Use the white stickers (solid) included with the machine

Hold your finger firmly on the LCD screen, and then turn on the machine

Press the “Automatic Threading” button

Follow the on-screen instructions to complete the procedure

The operation is finished when “OK” appears

The needle position controls the amount of fuel that is delivered to the engine. Raising the needle delivers more fuel, and lowering the needle delivers less fuel.

What does adjusting needle clip do?

If you want to change the petrol/air mixture in the mid engine range of revs, you can do so by moving the needle up or down. If you move the needle up, it will make the mixture richer. If you move the needle down, it will make the mixture leaner.

Needle insertion is a critical step in injection technique. The needle must be inserted at a 90o angle to the skin with a quick thrust. The person administering the injection must retain pressure on the skin around the injection site with the thumb and index finger while the needle is inserted. This helps to prevent the needle from being inserted too deeply and also helps to ensure that the medication is injected into the subcutaneous tissue, rather than the muscle.

Warp Up

There is usually a small lever or knob on the side of the sewing machine that controls the needle position. Depending on the model of machine, it may be labeled with numbers or symbols that indicate the different positions. To adjust the needle position, simply turn the knob or lever to the desired position.

There are a few things you can do to adjust the sewing machine needle position. First, you can try moving the needle to the left or right. If that doesn’t work, you can try adjusting the tension. Finally, if all else fails, you can always take the machine to a professional to have it fixed.