Sewing is one of the most enjoyable hobbies for many people. Knowing how to change a needle on a hand sewing machine is among the basics of the craft – and it’s pretty easy to do. You’ll need the right type of needle, as well as a screwdriver and a few minutes of your time.

When looking for a needle, consider the weight and texture of the fabric you’re working on, as well as the stitch you want to make. The right needle should match the fabric and the thread that you’ll be using for the project.

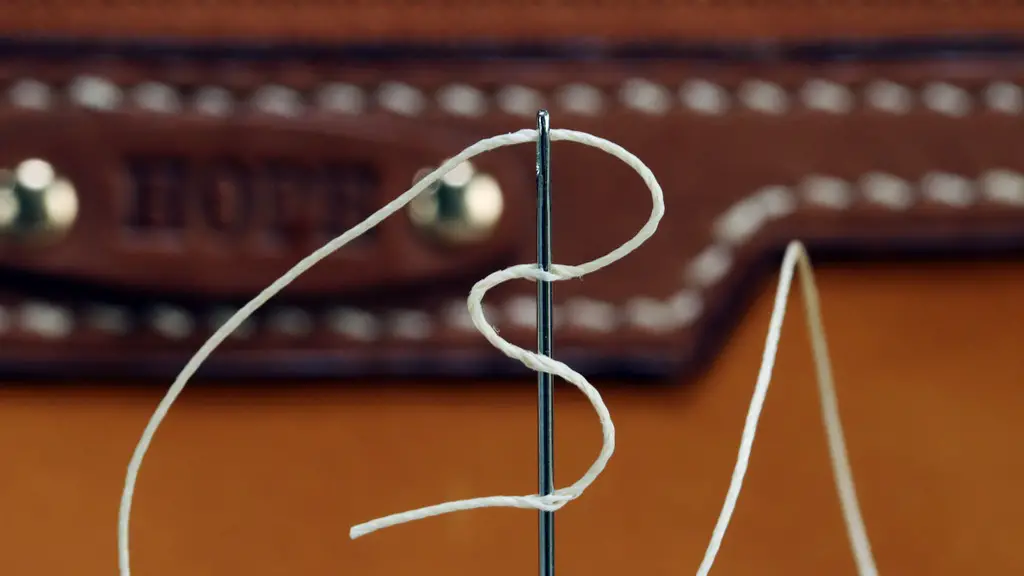

A size 90/14 needle is suitable for light to midweight fabrics when stitching with a standard polyester thread, while a size 80/12 needle is good for heavier fabrics and thicker threads. You should also check the eye of the needle – it should be the same size or smaller than the thread you’re using. Make sure the needle is sharp so the fabric won’t be damaged while sewing.

Once you’ve got the right type of needle, make sure the power is disconnected and then carefully remove the needle plate by loosening the fixing screw on the machine. Lift the needle plate away and you’ll find the needle bar. Loosen the thumbwheel that is used to fix the needle, then unscrew the needle shank out of the needle bar.

Now insert the new needle into the slot, making sure the flat side of the needle shank is facing the back of the machine. Tighten the thumbwheel and fix it in place. You should also lower the needle bar to the lowest position and make sure that the needle is straight and tight in the clamphousing.

Finally, check that the needle has been properly fixed by slightly tapping it from the front of the machine. If it moves, it isn’t secured correctly. You can also check the needle is in the correct position by pressing down lightly and turning the wheel; the needle should pass through the fabric when tested.

Preparing the Machine

Before you get started, make sure the machine is in good working order. Oil and lubricate it before changing the needle – this will ensure it runs smoothly and prevent damage.

Before you start the process, make sure you turn off the machine. You should also remove any pins and threads from the machine before you change the needle. Make sure the area is clear of all objects, as these can be hazardous when changing the needle.

Read your machine’s manual beforehand and familiarize yourself with the process, as each machine will be different. Check to make sure all parts are in place, as this is key to a successful needle change.

Conclusion

Changing a needle on a hand sewing machine is a straightforward process, but you should be careful and take the necessary precautions. With the right needle and a screwdriver, you’ll have your machine sewing in no time at all.

Tools for the Task

It’s best to use the correct tools when changing a needle. Professional sewers recommend using a screwdriver that fits the machine, as this will make it easier to secure the needle. If the screwdriver is too big, it will damage the machine. You should also use the screwdriver that came with the machine, as other types may not be compatible.

It’s also important to only use the exact tools specified in the machine’s manual. This may involve using a lint brush to remove any loose threads, or a screwdriver to loosen and tighten the needle shank. Any tools that are not specifically listed can damage the machine.

Clean and sharpen the screwdriver before you begin and lubricate the machine to prevent any damage, as well as to make sure the needle is fitted correctly. Dull needle plates may need to be replaced or reseated with the needle shank.

Security Tips

Before you start to change the needle, make sure you practice safety measures. Wear protective clothing, such as safety goggles and gloves, when working with needles, as this will protect your eyes from any sharp objects. Make sure the electric cord is not plugged in, and store it in a safe place when not in use.

Be sure to disconnect the power when changing the needle and read the machine’s manual thoroughly so you understand the process. Test the machine after the needle has been changed. If it is not working properly, contact a professional before using it.

Finally, never leave the machine unattended while it is running. Keep it away from children and animals and make sure it is locked when not in use. Also store the needles in a safe, secure place to prevent any accidents.

Needle Adjustment

When the needle is changed, you may have to make some adjustments to the needle plate or the machine’s tension. If the thread is not readily visible, you may need to adjust the machine’s tension by turning the tension adjuster. This will allow the thread to pass through the fabric more easily.

It is also important to check the needle size before using the machine. This will ensure it is the right size for the type of fabric and thread you are using. If the needle is too small, the fabric may be damaged while stitching.

Make sure the needle plate is in the correct position before testing the machine. This will help ensure the needle is hitting the fabric in the right spot, as well as avoiding any snags or skipped stitches. Be sure to test the machine after each adjustment.

Choosing a Type of Needle

When selecting a needle for hand sewing machines, there are a few factors to consider. The weight and texture of the fabric plays a key role in the type of needle you should use. Generally, a size 90/14 needle is suitable for light to mid-weight fabrics when stitching with a standard thread, while a size 80/12 needle is good for heavier fabrics and thicker threads.

You should also check the eye of the needle – it should be the same size or smaller than the thread you’re using. Make sure the needle is sharp so the fabric won’t be damaged while sewing. Check the shank of the needle too, as it should fit the machine securely and be in the right position.

The type of stitch you’re using is another factor that can help you in selecting the right needle. For a basic straight-stitch, a size 70/10 is the best choice, while for a tailored stitch, a size 90/14 is ideal. The thicker the fabric, the larger the needle size.

Alternative Needles

Hand sewing machines are designed to accommodate several types of needles, from the standard sharp needles to the more specialized needle types. For example, quilting needles have a special design that allows them to stitch through many layers of fabric, making them great for quilting projects. Embroidery needles also have a larger eye, and are designed to work with specialty threads.

Stretch needles are also available, and are best used for knit fabrics and elastic material. They are designed to pass through the fabric without damaging it, as they have a unique angled groove that prevents skipped stitches. Topstitch and ballpoint needles, as well as twin needles, can also be used with hand sewing machines.

It’s best to experiment with the different types of needles to get the results you’re looking for. While there is no ‘right’ needle, with the right tools and knowledge, you can achieve great results with your hand sewing machine.