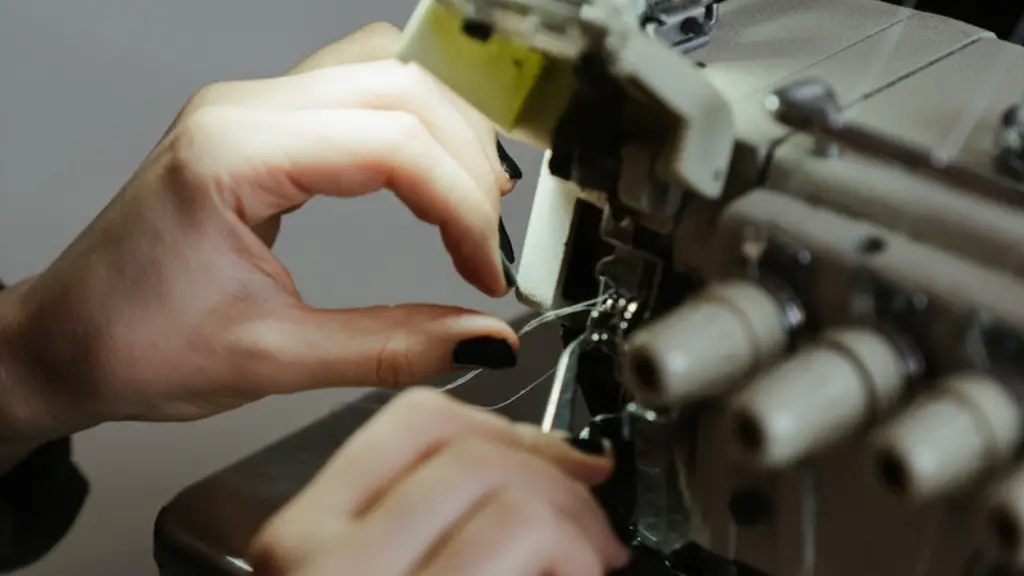

Maintenance of industrial sewing machine

Industrial sewing machines are one of the most vital components of many factories, warehouses and businesses. They are built to last, but they do require regular maintenance and occasionally parts may need replacing. Adjusting the tension on an industrial sewing machine is a key part of this regular maintenance. Doing the adjustment correctly will ensure that the threads remain tight while in use and guarantees a high-quality end product. Knowing how to properly adjust the tension on an industrial sewing machine is simple, but it is important to pay attention to minor details to ensure proper tension for the best results.

The tension of the thread is what controls how the finished product will look. If the thread is too tight, the stitches may be visible, and the fabric distorted. If the thread is too loose, the stitches will become very loose and may actually unravel. To make sure that the thread tension is correct, it is important to be aware of the adjustments that can be made. Generally, the tension adjustment knob is located near the thread path of the sewing machine.

In order to make sure that the tension is correct, one needs to observe the tension disc, which is a round disc which can turn. This disc has a hand wheel on one side, and a dial on the other side. The hand wheel will generally be used to adjust the tension, but make sure to also check the dial for accuracy. If the disc is not turning, then the hand wheel will need to be adjusted. This can be done by turning the dial clockwise, or counterclockwise, depending on what type of tension needs to be adjusted.

The pressure bar should also be observed to make sure that the tension is correct. This bar holds the fabric in place while the machine is running, thus helping to keep the tension just right. The pressure bar should be adjusted according to the tension needs of the item being sewn. Too much pressure can cause the fabric to stretch and create a distorted look, while too little pressure can cause the fabric to slip around, resulting in uneven stitches.

Seam Quality

The seam quality of the stitching is another important aspect of industrial sewing machines. This means the amount of stitching that is created and how it looks when finished. If the machine is creating stitches that are too small or too large, or the stitches themselves are uneven, then it could indicate that the tension needs to be adjusted. This is done by manipulating the tension and/or pressure settings according to the pattern and fabric being used.

Fabric is an important factor when it comes to industrial sewing machines. Different types of fabric will require different settings for the tension and pressure. Some heavier fabrics may require more tension than lighter materials, and some fabrics may need a smaller tension adjustment than others. This is why it is important to adjust the tension and pressure settings according to the fabric being used.

Thread types also need to be taken into consideration when adjusting the tension of an industrial sewing machine. Different types of threads draw different weights, and they may require different settings based on their weight. The weight and type of thread being used will determine how much pressure and tension need to be applied.

Finally, the thread tension will also require regular checking to make sure it is consistent. If the tension is off, the stitches may be weaker and the fabric may not look as desirable. Checking the tension settings every few weeks or months is a good way to make sure the tension remains consistent.

Professional Assistance

When adjusting the tension settings of an industrial sewing machine, it is best to seek the advice of a professional who is knowledgeable about the machine and knows how to set the settings correctly. A professional will be able to help adjust the settings so that the machine produces optimal results, especially with heavier fabrics and threads.

Additionally, always make sure to read the manual and to familiarise yourself with the parts of the machine before attempting any maintenance. Knowing the terminology and understanding the parts of the machine is paramount in professional sewing production. The more knowledge one has, the better the results.

Finally, when adjusting tension settings, always wear protective gear and follow applicable safety regulations. Industrial sewing machines can cause injury if used improperly, so take the time to learn the instructions and be safe.

Time Saving Strategies

Properly adjusting the tension on an industrial sewing machine can save a lot of time. This is because having a machine that is set up correctly and produces consistent results significantly reduces the amount of time it takes to complete a project. Having the correct tension settings will also result in less thread breakage, which is another time-saving factor.

To make sure that the machine is working properly and threads are not breaking, it is important to regularly check the tension settings, especially after a long period of non-use. This will ensure that the thread is tight enough to create quality stitches and tight enough that it does not break or loosen.

For those sewing large amounts of fabric, it might be helpful to invest in an automated system. This system can be programmed to adjust the tension settings automatically, which can save time and energy. Additionally, using a machine with a wide range of tension controls can be helpful in achieving the desired tension.

Keeping Thread Path Clean

To get the best results, it is important to keep the thread path clean and lubricated. Clean out any dust or lint that may have accumulated in the path and keep the machine oiled and lubricated. Also, make sure to regularly oil any screws and bolts found in the machine, as well as the tension rod. This will ensure that the machine functions properly and that the tension remains accurate for the best results.

Also, make sure to inspect the needle and thread tension settings from time to time in order to make sure they are correct. If the needle is constantly moving, the tension may not be correct, so it is important to make the necessary adjustments. Additionally, check the tension discs occasionally to make sure that the hand wheel is turning properly and that the tension discs are properly aligned.

Finally, it is important to periodically check the pressure bar settings to make sure the pressure is adjusted correctly. Too much pressure can cause the fabric to bunch up and create an uneven finish, while too little pressure can cause the thread to slip and cause an uneven stitch. Avoiding these problems by making sure that the correct pressure is set can help create quality and consistent manufactured products.

Preventative Measures

Regular maintenance of an industrial sewing machine is very important in order to ensure the quality of the final product. Replacing worn or damaged parts, inspecting for lint or other buildup, and lubricating the machine components can help extend the life of the machine and keep it running smoothly. Additionally, keeping a well-stocked inventory of thread and needles is essential, as well as having a large amount of spare parts on hand to ensure order completion.

Be sure to also keep the machine’s instructions and user manual handy, as this will provide important information on how to adjust the tension settings. This is especially important for machines that have a wider range of tension settings and require more extensive adjustments.

Finally, it is important to inspect the fabric regularly, as this will help to detect any tension inconsistencies. Thread breakages and fabric that pulls too tightly can be signs that the thread tension needs to be adjusted.

Troubleshooting Problems

Sometimes problems can arise with the sewing machine even after all of the maintenance has been done. Common issues include poorly placed tension knobs or faulty pressure bars. Fortunately, these problems can usually be fixed fairly easily. It is important to consult the manual before attempting to troubleshoot any problem, especially if the machine is new.

Another common problem is thread breakage. If the tension settings are not set correctly, the thread will experience higher tension and may break. This can result in costly delays, so it is important to adjust the tension settings and make sure the threads are not too tight.

Finally, if the fabric appears to be distorting or bunching up, it could be a sign that the tension needs to be adjusted. It is important to adjust the machine’s settings according to the fabric being used and ensure that the pressure bar is properly set up.