Basic Tips to Adjust Thread Tension on Janome Sewing Machine

An important skill for anyone who owns a Janome sewing machine is the ability to adjust thread tension. The tension of the thread can make the difference between an excellent and an inadequate project, or worse yet, a project that fails all together. Without the proper tension, the fabric stitches may be uneven, tight, or not secure. Luckily, adjusting thread tension on a Janome sewing machine is easy, and anyone can master the technique with patience and practice.

The thread should be tight enough that the stitch on the fabric is tight and even, but not so tight that it causes rippling or puckering. It is important to remember that, depending on the type of project, the thread tension should be adjusted accordingly. For example, a looser tension is best for topstitching, while a slightly tighter tension is ideal for quilting.

Check the Owner’s Manual for Instruction

The first step in the process is to check the manual for instructions on how to adjust the tension on the Janome machine. The manual typically indicates where and how to adjust the thread tension, and depending on the model, the process may require turning a knob or pushing a button.

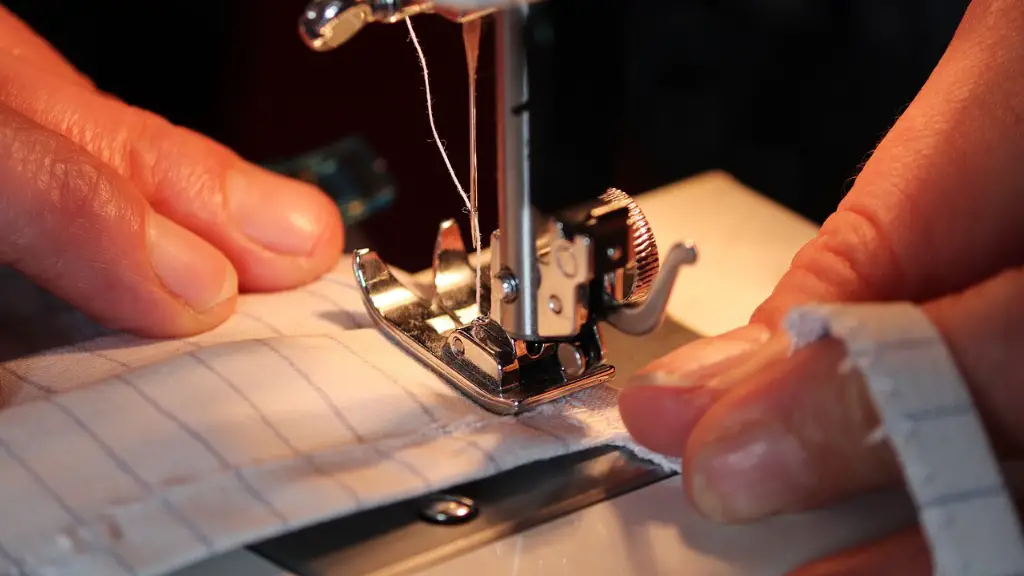

Test Stitches on a Sample Piece of Fabric

Once the tension has been adjusted on the Janome sewing machine, it is important to test the stitch on a piece of scrap fabric. This helps to ensure that the tension setting is correct before sewing the actual project. The stitch should be even and consistent on both the top and bottom layers of the fabric. If the stitch is not even or is causing the fabric to pucker or pull, the tension needs to be adjusted.

Adjust the Thread Tension Knob

If the stitch test does not look right, the tension may need to be adjusted. Most Janome sewing machines have a thread tension knob located on the front or side of the machine. Turning the knob clockwise will make the tension tighter, while turning it counterclockwise loosens the tension. After each adjustment, it is important to test the stitch on scraps of fabric until a satisfactory stitch appears.

Testing Different Threads

Thread choice can also affect the tension of a project. Testing different threads can be a good way to find the best combination for a given project. For example, heavier threads, like embroidery floss, tend to need a tighter tension setting. On the other hand, lightweight threads, such as polyester or cotton, usually require a looser tension setting.

Using a Thread Stand

Using a thread stand can also be helpful in adjusting the thread tension on a Janome machine. Thread stands are designed to hold the thread spool in place while the machine is operating and take the strain off the machine, which can help to ensure that adequate thread tension is maintained. It is important to note, however, that the type of thread stand used needs to match the machine model.

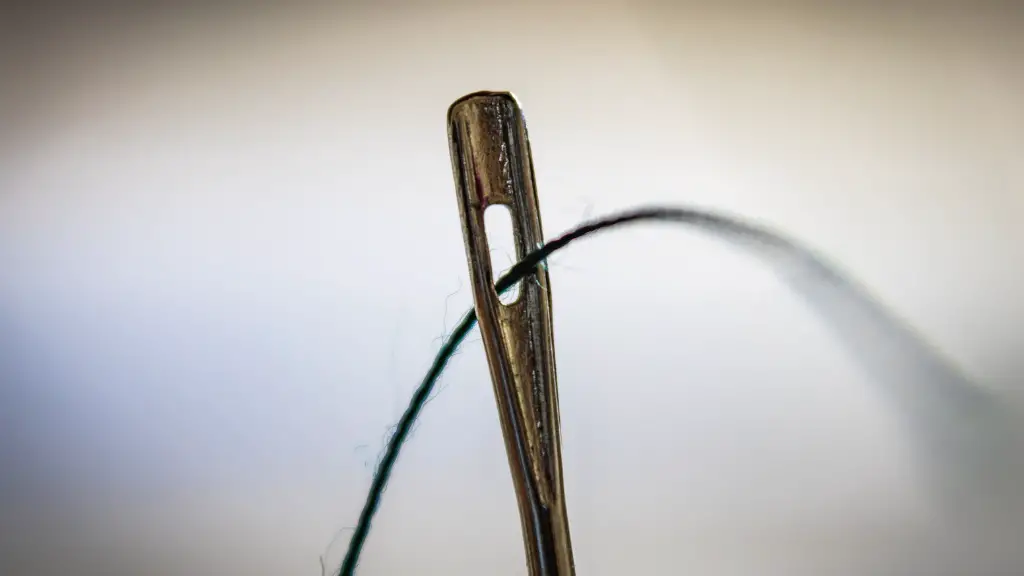

Thread Sizes and Weights

When selecting thread for a Janome sewing machine, it is important to take thread size and weight into consideration. Thread come in a range of sizes from very fine to very thick, so it is important to select a thread that is the appropriate size and weight for the project. If the thread is too thick or too thin for the project, it may cause tensioning problems. Thread weight can also affect tension, so it is best to choose thread that is lightweight for the project. It’s a good idea to test the thread on a sample piece of fabric before beginning the project to ensure the right size and weight of thread is being used.

Matching Thread and Needle Size

Another important factor to consider is the needle size. When selecting a thread size it is important to use a needle that is the same size, or slightly larger, than the thread. Using a needle that is too small can cause tensioning problems, while a needle that is too large can cause the thread to be cut while sewing and potentially cause the project to fail.

Correcting Thread Tension

Correcting thread tension on a Janome sewing machine is simple as long as the proper techniques are used. With patience and practice, it is possible to achieve perfect tension for any type of project. The key is to remember that thread size and weight, as well as needle size, should be considered when selecting thread for a project and when adjusting the thread tension knob. Testing the stitch on a sample piece of fabric after each tension adjustment is also important, as this will help to ensure that the tension is just right for the project.

Cleaning the Machine Regularly

Regularly cleaning the machine is also an important part of the thread tensioning process. Dust, lint, and thread buildup can cause tensioning problems, so it is important to clean the machine according to the instructions in the manual. This will help to ensure that the machine is running smoothly and is free of any obstructions that could affect the thread tension.

Keeping Multiple Spools of Thread Handy

Finally, it is beneficial to have multiple spools of thread on hand for different types of projects. As previously mentioned, different threads require different settings for tension. Having multiple spools of thread can help to ensure that the correct thread is always available and the tension can be adjusted quickly and easily.

Troubleshooting Thread Tension Issues

Troubleshooting thread tension issues is an important skill to master. When there is a tension issue, it is important to identify the cause, as it could be anything from a worn or incorrect needle, to incorrect thread size or tension settings. If the cause of the issue is not clear, it is a good idea to consult a sewing machine expert or check the machine manual for more information.

Checking Thread Quality

Another good way to ensure that thread tension is correct is to check the quality of the thread. Thread quality can affect tension, so it is important to make sure the thread is strong and does not easily break or fray. If the thread is weak or has noticeable knots, it is best to choose a different thread for the project.

Investing in Good Supplies

It is also important to invest in good quality supplies, as these can make all the difference when it comes to thread tension. Needles and thread should be of high quality and adequate for the project, as poor quality supplies can contribute to tensioning problems.

Considering Different Tension Settings

Finally, it is important to consider different tension settings. Experienced sewers know that the tension needs to be adjusted for different types of fabrics, thread weights, and projects. Taking the time to adjust the thread tension accordingly will help to ensure a successful project.