If you’re looking to start sewing with a Brother sewing machine, you’ll need to know how to align the needle. This is a simple process that only takes a few steps. First, you’ll need to make sure that the needle is in the highest position. Next, you’ll want to loosen the set screw that holds the needle in place. Once the set screw is loosened, you can then adjust the needle to the left or right, depending on your preference. Finally, once you have the needle where you want it, be sure to tighten the set screw again.

The needle on a Brother sewing machine can be aligned by first loosening the screw that holds it in place. Once the screw is loosened, the needle can be moved up or down to align it with the needle plate. To tighten the screw, hold the needle in place and use a screwdriver to tighten the screw until it is snug.

How do you align a sewing machine needle?

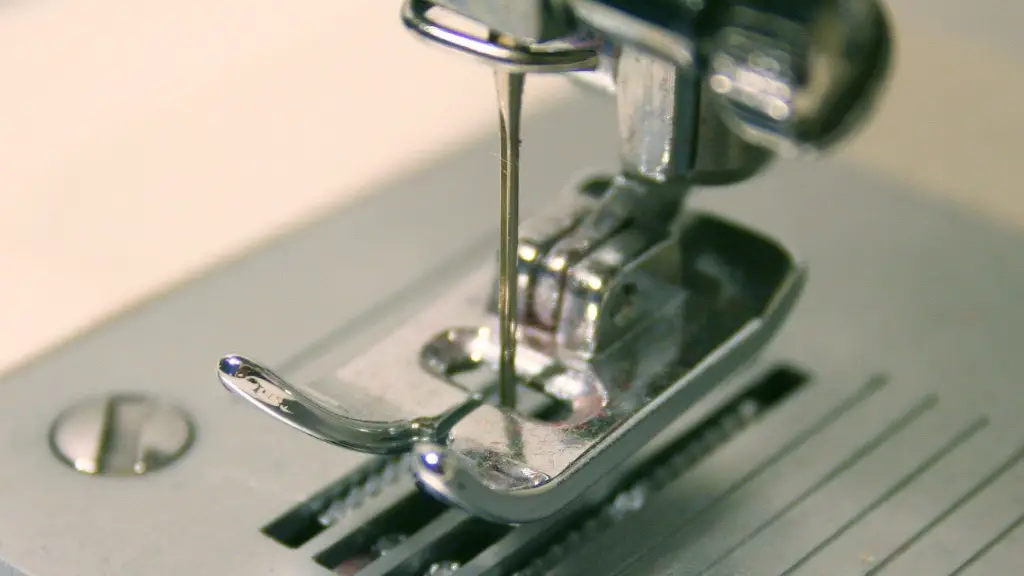

This is your needle board. So right over here that screw you see there, each machine have it. This is what you’re going to use to change your needles.

This is normal, as there is no adjustment on the Featherweight for the position of the needle. A smaller size needle will sit on the left side of the needle hole in the throat plate, but a larger needle will be more centered.

Why is my brother sewing machine needle hitting the foot

If you’re having trouble with your stitches, it might be because you’re using the wrong presser foot. Make sure you’re using the right presser foot for the type of stitch you want to sew. Also, check that the needle isn’t bent. If it is, replace the needle.

If you are pulling the fabric through and the needle is bending, this means the timing is out. The needle will hit the bobbin case and snap if you continue to pull the fabric through. If the user has been pulling the fabric through and jammed the machine or snapped a needle, the timing may be out.

How do I move the needle position on my brother?

The straight stitch is the most basic of all stitches and is the foundation for most other stitches. The needle position can be changed by pressing the plus (+) side of the stitch width adjustment key, which moves the needle to the right. Pressing the minus (-) side of the stitch width adjustment key moves the needle to the left. The triple stretch stitch is a variation of the straight stitch that is often used for stretchy fabrics or for decorative purposes. It is created by stretching the fabric slightly as you sew, which creates a series of small loops on the back side of the fabric. Like the straight stitch, the needle position can be changed by pressing the plus (+) or minus (-) side of the stitch width adjustment key.

If the needle is hitting the needle plate, it is likely that the wrong needle plate is on the machine. This can happen if the stitch you are trying to sew is not compatible with the needle plate. If all is as it should be – needle plate correct, etc. – and the needle is still striking the needle plate, you’ll need to make a trip to the dealer to have it fixed, as something is out of alignment.

How do you adjust a needle bar?

There is usually a small hole in the arm of the needle that is used to draw blood. The clamp is used to close off this hole so that no blood is drawn. Sometimes, the clamp can be difficult to find. In most cases, it is just a matter of looking for it.

In order to ensure that your needle is inserted properly, be sure to insert it with the flat side facing left. Make sure that the needle is all the way into the shaft before tightening the needle clamp thumb screw. Before you begin sewing, turn the handwheel of your machine slowly towards you by hand to double check that everything is in place.

What part of sewing machine controls the needle

The hand wheel on your sewing machine controls the movement of the take up lever and needle. You can control the hand wheel either by power or by hand. Always turn the hand wheel toward you.

If you’re having trouble with your sewing machine needle, check to see if the needle is installed correctly. The flat spot on the needle should face the back of the machine. Also, make sure the needle clamp screw is tight.

How do you fix a walking foot on a sewing machine?

A screwdriver can be used to hand-tighten a screw, and then the wheel can be rotated to bring the object closer or further away. This is a useful tool for adjusting the position of an object.

Often, this sound comes from not getting your thread in the take-up lever while threading If you have a new needle that is the appropriate size/type and your machine is clean, but you start to hear a clunking sound after rethreading, this is the first thing to check.

How do you fix a bent needle

The trick to creating perfect curls is to first straighten the hair out, then pull it backwards and rotate it at the same time. This will create beautiful, bouncy curls that will last all day long!

Sewing straight lines can be tricky, but with a few simple tips it’s easy to get perfect results every time. Here are our top tips:

1. Create a visual reference point: Use a piece of tape or a fabric marker to create a line to follow. This will help you keep your stitches nice and straight.

2. Use a specialist presser foot: Some presser feet have a guide on them which makes it easy to sew a perfect seam.

3. Don’t watch the needle! Instead, focus on the seam line and guide the fabric gently so that it doesn’t pucker or pull.

4. Fabric position: Make sure the fabric is positioned correctly before you start sewing. This will help prevent the fabric from shifting and resulting in crooked stitches.

5. Guide the fabric, don’t pull: Gently guide the fabric through the machine, being careful not to pull or stretch it.

6. Adjust your Needle Position: If your machine has this feature, it can be helpful to adjust the needle position so that it’s closer to the fabric edge. This will help prevent the fabric from shifting.

7. Take your time! Don’t try to sew too fast,

When sewing the flat side of the needle faces in what side?

The needle is one of the most important parts of the sewing machine, as it is the component that actually does the stitching. Needles come in many different sizes and types, depending on the type of sewing you are doing. There are also different types of needles for different types of fabrics.

The needle position option is a great way to ensure that your stitches are sewn exactly where you want them. By using the guides on your presser foot, you can easily adjust the position of the sewing machine needle to get the perfect results every time.

Conclusion

1. Begin by attaching the needle to the machine.

2. The next step is to raise the needle.

3. Use the handwheel to lower the needle into the fabric.

4. Finally,align the needle with the Mark on the needle plate.

After threading the needle on your Brother sewing machine, you will need to align the needle. First, check that the needle is in the vertical position. Then, using the needle clamp screw, loosen the needle so that it can be moved side to side. While holding the needle in place, tighten the screw. Once the needle is tightened in place, it should be aligned with the needle plate.