Part 1: Attaching Feet to Singer Sewing Machines

Singer sewing machines have been around for many decades, providing people with high-quality crafting solutions. Singer machines are well-known for their robustness and durability, as well as for being easy to take apart and reassemble. In relation to taking apart and reassembling a Singer machine, one of the most important steps is attaching feet to the machine.

Pressing feet can add a lot of versatility to a Singer machine and make a big difference to projects. Being able to accessorize Singer machines with different feet can make them capable of a myriad of tasks, from fashioning buttonholes to contouring fabric. Taking too long to attach the feet to the machine, or attaching them incorrectly, can create frustrations. Therefore, it is important to make sure that the attachment of a foot is done efficiently and correctly.

Part 2: Checking the Machine Components

Before attachment of the foot to the Singer machine, it is important to check that all the components are present. This includes checking that the foot presser, needle clamp, and needle bar are all in their correct positions. Additionally, it is important to check that the gear is correctly engaged at the rear of the machine, as it can affect the position of the needle.

Now the machine is ready for the foot to be attached. It is important to note that all feet are not the same size and model. Matching the correct foot with the correct Singer machine is essential as it can avoid several complications. Making sure the lever and presser bar can be correctly adjusted with the foot is also key.

Part 3: Attaching the Foot

The process of attaching a foot to a Singer machine is very straightforward. To attach the foot, the machine should be in a raised position. If it is not already in a high position, the lever can be moved to the back of the machine.

Once in the raised position, the presser bar needs to be moved up as far as possible to make sure it is completely free. This can be done by turning a small screw in the presser bar, clockwise until it nearly comes out. Once the presser bar is out of the way, the foot can be pressed firmly onto the machine and slid and then twisted into position.

Part 4: Locking the Foot

Once the foot is in place it will need to be locked and then checked for correct attachment. To lock the foot into place, the metal lever at the back of the feet will need to be lifted and then pulled gently towards the back of the machine. This should create a small gap between the foot and the presser bar, which will be enough for the foot to be secured.

After the foot has been secured with the metal lever, it is important to one lay the foot flat on its back and check that the presser bar is sitting in the slots both at the back and front of the foot. Additionally, the screw in the presser bar needs to be checked, to make sure it is engaged in the slot in the foot.

Part 5: Adjusting the Presser Bar

Once the foot is attached securely and the presser bar is in place, it is important that the pressure on the presser bar is adjusted correctly. This ensures that the machine will not be put under a great deal of pressure when sewing, where the fabric can get snagged by the foot.

The presser bar can be adjusted quickly by turning the small screw in the presser bar counter-clockwise. This will increase the pressure of the foot on the fabric, taking the pressure off the machine. It is important to note that the presser bar will need to be adjusted for each different foot that is attached to the machine, depending on how much pressure is needed.

Part 6: Testing the Foot

Once the foot is adjusted correctly it is important to do a test of the attachment. To do a test, fabric should be placed on the machine and can then be moved back and forth. If there is any friction between the fabric and the foot that indicates that the foot has not been attached correctly.

If the fabric does move freely it is important to also check that the needle position is correct. To do this, fabric should be placed under the needle and the position can be checked with again a quick test of the machine. A Singer machine is designed to have the needle go through the fabric before the foot carries out any task with the fabric.

Part 7: Making Adjustments to the Needle

The needle position may need to be adjusted to ensure that the foot is working correctly. The needle should be in a straight position and if it is not, it can be adjusted by turning a small screw at the top of the needle bar. The screw needs to be turned counter-clockwise and stopped when the needle is in a straight position. This can be done while the fabric is still in place.

Once the needle is in the correct position, it is important to change the position of the needle back to its original spot. This ensures that the fabric will not become wedged in the machine when the next task is carried out. Again, it is important to do a quick test with the machine to make sure that the needle is in the correct position.

Part 8: Ensuring the Correct Tension of the Thread

For smooth operation of the machine, it is essential to have the correct tension of thread when the machine is on. If the tension of the thread is too loose the thread will come off the needle more easily, causing complications when carrying out tasks with the fabric.

The tension of the thread can be adjusted by turning the dial on the machine which should be found near the little fingerwheel. This can be turned right or left and adjusted slightly until the thread is not too loose or too tight when running the machine. It is important to test the machine once the tension has been adjusted and make sure it is working correctly before moving onto the next task.

Part 9: Ensuring the Foot is in the Correct Position

Before carrying out any task with the foot, it is important to make sure it is in the correct position. This can be done by turning the little fingerwheel on the right of the machine. This should be turned until the presser foot is able to secure the fabric under the foot without any complications.

The foot can now be used for various tasks. It is important to do a quick test before engaging in a lengthy task, with the machine. This can be done by running the machine with no fabric to make sure that the foot is properly adjusted and the tension of the thread is correct.

Part 10: Checking the Accessory Kit

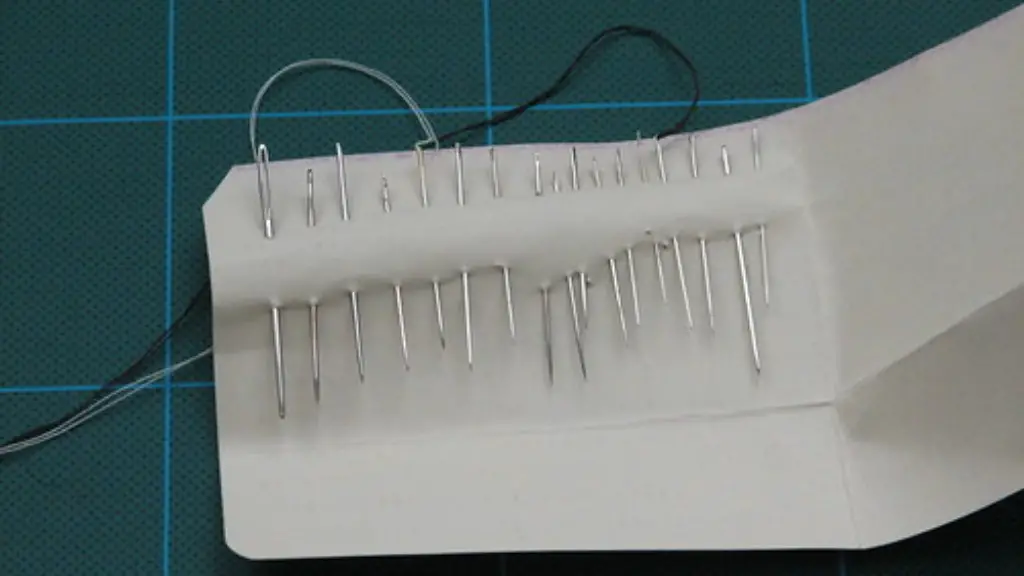

When finally attaching the foot to the Singer machine it is important to check the accessory kit to makes sure that all items are present. This includes checking for left and right-hand needles for different fabrics, as well as different shanks and guide screwdrivers. There should also be spare parts such as a special screwdriver and two extra generic screws as they might be needed during repairs or while attaching the foot to the machine.

If any part is missing, it is possible to purchase them directly from the Singer website. It is important to take the right measurements and make sure that the parts that are purchased are compatible with the make and model of the machine. Failure to do so can cause complications while trying to attach the foot.

It is important to note that attaching the foot to the Singer machine is a relatively quick process, taking only a few minutes. Taking the time to make sure the foot is correctly looked before using will ensure that the machine runs smoothly and efficiently. A correctly attached foot to a Singer machine will not only provide great results but also provide comfort and satisfaction in the sewing process.