Learning to calibrate a sewing machine is a skill that comes with many benefits including improved consistency, reduced strain, and more professional-looking garments. But before one can appreciate the rewards that come with this craft, they must understand the importance of calibration and how to do it properly. In order to have the best experience with a machine, it is essential to periodically adjust its settings and configurations.

To start, it is important to understand what components of the machine need to be calibrated. Generally, a sewing machine should have the presser foot tension, the upper and lower thread tensions, and the needle position adjusted on a regular basis. Each of these processes will require different tools and configurations depending on the make and model of the machine. With a few exceptions, the presser foot tension and the needle position will usually be the same for any given machine. It is highly recommended to consult the owner’s manual for detailed instructions on how to properly adjust each of the relevant parts.

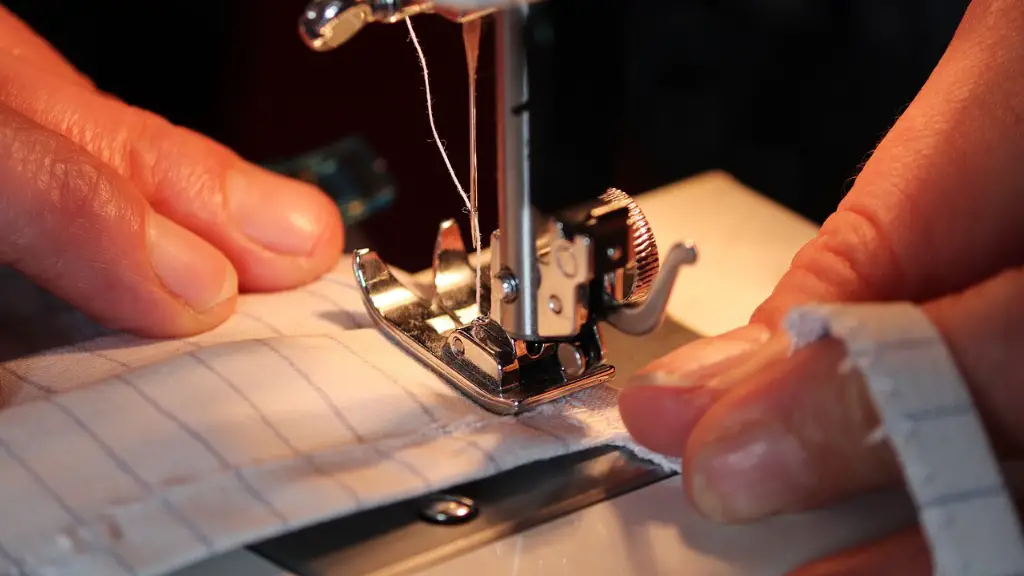

Once a user has found the appropriate settings in their manual, they can begin making adjustments. It is typically best to begin with the presser foot tension. This is adjustable using a calibration screw that can be accessed either from the top or the side of the machine. This will determine how much tension the foot applies when pressing against the material. A simple way to test the setting is to hold the machine in one hand and place a sample fabric under the presser foot. Checking the beep/clicking sound of the machine will allow the user to determine how much pressure is being applied.

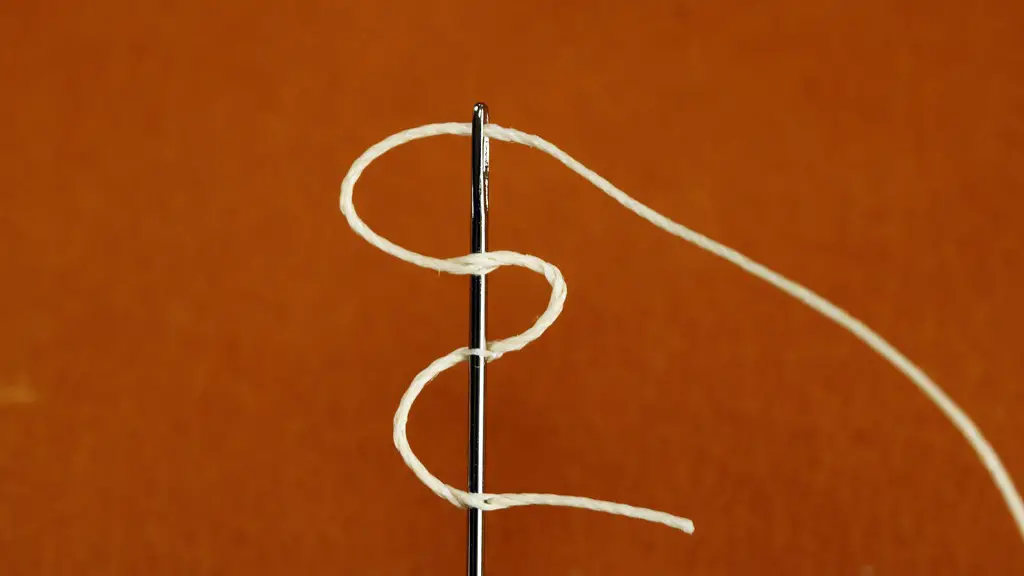

In the next step, it is important to adjust the thread tension. This is the pressure that is applied by the upper thread when stitching. It is important to adjust this setting correctly because if it is too tight, the thread could break and if it is too loose, the loop formation could be too loose. Generally, the recommended tension setting will depend on the type of fabric being used. Once the user has determined the ideal setting, they can use a screwdriver to change the level of pressure.

Finally, the needle should be adjusted to the correct height. This will depend on the type of sewing being done. For example, it may need to be set higher if the material being used is thicker. It is important to note that this particular setting can be easily damaged and needs to be checked regularly.

After all these adjustments have been made and checked, the sewing machine should be ready to use. Making these regular calibrations can help to ensure that the machine is producing the best quality of garments possible. With experience, users will be able to quickly and easily make the adjustments as needed.

Ensuring Quality Results

Calibrating a sewing machine is one of the most important steps in creating quality garments. When the machine is adjusted properly, it can help to reduce the strain involved in stitching and improve the consistency of the results. There are several types of machines, but the principles of calibration remain the same. It is important to consult the owner’s manual, as different machines may require different settings and tools.

When making adjustments, it is necessary to take into account the type of fabric being used. These will usually require different settings for the presser foot and thread tensions. There are also other important factors to consider. For example, when calibrating the needle, it is important to pay attention to the height and make sure that it is correctly aligned.

When a user takes time to periodically calibrate their sewing machine, they will be able to get better results with precision and accuracy. As with any skill, practice will help to improve the results. By taking the time to adjust the machine properly, the user can then enjoy the rewards that come with wearing a well-crafted garment.

Advantages of Calibration

The benefits of calibrating a sewing machine on a regular basis are numerous. Not only does it help to improve the quality of the garments being created, but it also reduces the strain and wear that comes with using the machine. This is important to ensure that it lasts as long as possible.

Another major advantage is that it results in a more professional appearance. When a machine is properly calibrated, it ensures that the garments will look their best. This can be especially important when it comes to stitching multiple pieces of fabric together.

Calibrating a sewing machine is also a way to help the user understand the capabilities of the machine and the different settings and features. Over time, this will help to improve the user’s overall skill and knowledge.

Lastly, calibrating the machine regularly helps to free up the user’s time. It takes a fraction of the time to adjust the settings as compared to constantly having to correct errors due to improper calibration.

Tools For Calibration

In order to properly calibrate a sewing machine, the user will need to have the right tools. Generally, they will need a few basic items including a screwdriver and a sample fabric. They may also need a calibration screw and additional tools depending on the type of machine being used. It is best to consult the owner’s manual in order to determine what additional tools may be needed.

One of the most important tools for calibrating a sewing machine is a sample fabric. This is what the user will use to test the calibration settings as they are being made. This can be any type of fabric, as long as it is similar to the type of material that will eventually be used when sewing garments.

It is also important to have a screwdriver on hand. This will allow the user to adjust the calibration settings. Depending on the model, this may require a Torx head, Phillips head, or a flathead.

The most important tool of all, however, is the user’s manual. This will provide clear instructions on how to properly adjust the settings. It is highly recommended to consult the manual before making any adjustments, as each model may require different tools and configurations.

Troubleshooting Issues

When working on calibrating a sewing machine, it is important to be aware of potential problems that could arise. One of the most common issues is a broken needle or presser foot. If this occurs, it is important to replace it as soon as possible in order to avoid any further damage to the material or to the machine itself.

Another potential problem is the thread tension. If the tension is too tight or too loose, it could affect the quality of the finished product. When troubleshooting this issue, it is important to check that the settings are correctly adjusted. Once this is done, the user should check the owner’s manual for the proper tension settings.

Lastly, there may be times when the needle is not correctly aligned. This is particularly important when dealing with thick fabrics as the settings may need to be adjusted accordingly. To rectify this issue, the user should use a ruler to check the needle position and adjust it if necessary.

Safety Considerations

When calibrating a sewing machine, it is important to take certain safety precautions. To start, it is essential to make sure that the machine is unplugged before making any adjustments. This prevents the risk of electrocution as well as damage to the machine itself.

It is also important to remember not to force any parts in the machine. Doing so could cause serious damage and could even injure the user. The user should always make sure that the machine is working correctly before beginning any type of stitching.

It is also essential to wear the appropriate clothing for the task at hand. Loose wires, cords, and buttons can become tangled in the material and can cause serious injury. It is best to wear form-fitting clothing and tie back any loose strands of hair.

Finally, it is important to never leave any tools lying around. Small screws and other pieces can easily be lost and could cause problems when the user is trying to work on their machine. This is particularly important if the user has children in the house.