Changing a Needle in a Sewing Machine

Changing a needle in a sewing machine is one of the most basic maintenance tasks for any sewer. It is important for a sewer to know how to do this properly as it is vital for the machine to run efficiently and for fabrics to be stitched correctly. A dull needle can cause skipped stitches, pulled threads, uneven stitches, fabric puckering, and even broken needles. To get the best results, it is important to regularly clean and lubricate the machine as well as change the needle.

To do this, the first step is to switch off the machine and unplug it from the wall before taking off the light cover or the bobbin cover. It is then important to inspect the needle for visually for signs of damage. Sewers should look for any nicks, flat spots or rust, which indicate that the needle is dull and needs to be replaced. If the needle is damaged or dull, it is time to replace it.

Before beginning the process of changing the needle, it is important to make sure that the needle is the correct size, type and style for the fabric being used and the machine itself. Sewers should make sure to get the right size, as if the needle is too thin or thin, it can cause skipped threads or skipped stitches, while too thick of a needle can make it difficult to thread the needle.

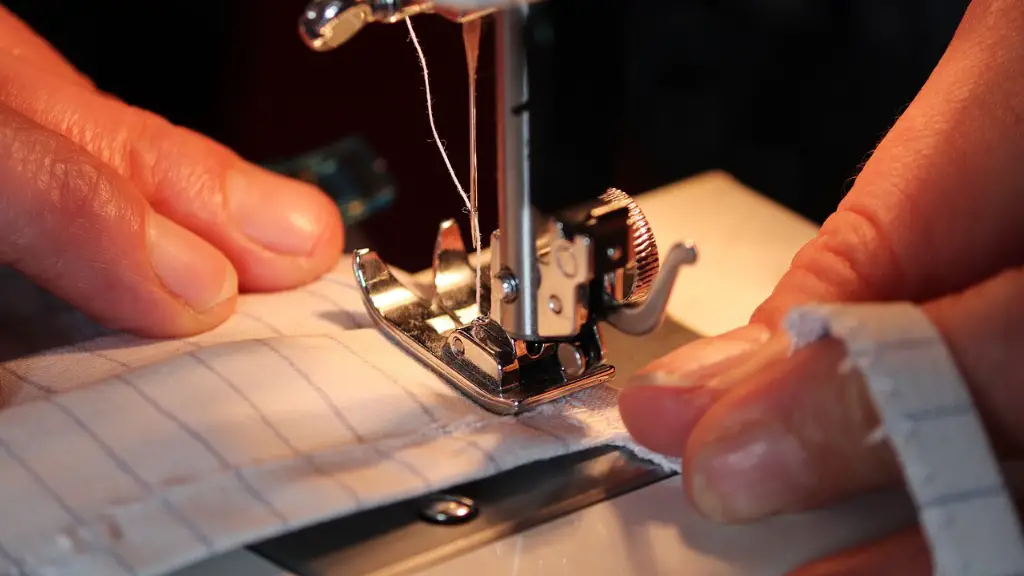

To proceed with changing the needle, the sewer should loosen the clamp that holds the needle in place and then remove the old needle by pulling it out of the machine. The sewer should then insert the new needle with the flat side facing the back of the machine and push it up as far as it can go, ensuring that it is firmly placed in the machine. The sewer should then tighten the needle clamp and double check to make sure that the needle is secure.

Once the new needle has been installed, it is important to adjust the needle height to match the fabric and the type of stitching that is going to be done. The needle should be set at the lowest level for straight stitching and at a slightly higher level for zigzag or other types of stitching. The sewer should then make sure to thread the machine and re-thread the needle for best results.

It is important for sewers to be familiar with changing needles in a sewing machine to get the best results. New needles should be changed every 8-10 hours of use, and sewers should take the time to check their needles periodically for signs of wear or damage. In doing so, sewers can be sure that they will get the best results from their projects, while also ensuring that they don’t have to worry about problems that can be caused by a dull or damaged needle.

Maintenance of a Sewing Machine

Maintaining a sewing machine is essential to ensure that it runs well and produces good results. Regularly cleaning and oiling the machine, as well as replacing needles and other parts when needed, can help to keep a machine in optimal condition and prolong its life.

Sewers should regularly clean the machine, paying special attention to the bobbin case, the feed dogs, and the presser feet. These components should be regularly wiped with a soft cloth and kept free of lint and other debris. Oiling the machine periodically is also important to make sure that the moving parts are running smoothly. Sewers should refer to the manual to find out the recommended oiling schedule, as well as how often the parts of the machine should be cleaned.

In addition to doing regular maintenance, sewers should also make sure that the accessories that come with the machine are in good condition and functioning properly. This includes threading the machine with the right type and size of thread, as well as making sure that all of the bobbins, needles, and other parts are in good condition and free of defects. Making sure that the needle is regularly changed is another important part of sewing machine maintenance.

Regular maintenance of a sewing machine is essential for sewers to make sure that their projects turn out the way that they want. Those who take good care of their machines can be sure that their machines will last for years and will produce results that meet their expectations. Sewers should also refer to their machine’s manual for information on how to properly care for their specific machine.

Benefits of Sewing Machines

Sewing machines have long been used for sewing garments and quilts, and are a useful tool for those who enjoy crafting or for those who are looking to make their own clothes. Sewing machines offer a number of benefits and advantages over hand sewing, which can make them a great choice for sewers of all levels.

One of the biggest benefits of sewing machines is their speed and accuracy. Sewers are able to make stitches that are much finer and more precise than those that are made by hand, and the speed at which a machine can work means that sewers can finish projects much faster than they could with hand sewing. Machines also offer a much broader range of stitches, making it easier for sewers to find the perfect stitch for their project.

Modern sewing machines are also much easier to use than older models. Modern machines often feature computerized controls that allow sewers to easily adjust the settings and functions, while some even offer tutorials and automatic setting recommendations. This makes learning how to use and maintain a machine much easier than it used to be. Sewers can even purchase machines with automated threaders, cutting the threading process down to seconds.

Finally, sewing machines are also much more affordable than they used to be. For those who are just getting started with sewing, even a basic machines can offer a number of features and benefits and can often be purchased for a relatively low cost. This makes sewing machines an attractive option for those who are looking for an affordable and easy way to sew.

Tips for Choosing the Best Sewing Machine

When it comes to choosing the best sewing machine for a particular project, there are a number of factors to consider. The most important thing to consider is the type of fabric that is going to be used and the type of stitching that needs to be done. This will help to determine the type of machine that is needed and what features it should have.

In addition to the type of project, sewers should also take into account how often they plan to use the machine and what kind of budget they have. For more experienced sewers, a higher-end machine may be the best choice, while sewers who are just starting out may want to opt for a lesser expensive option. Budget is often a major factor when it comes to choosing the best machine.

Before choosing a machine, sewers should also do research to make sure that they are getting the best possible deal. This means reading reviews and comparing prices between different models. Sewers should also make sure to read the machine manual to make sure that they have a good understanding of how the machine works and what its features are.

Finally, sewers should take the time to make sure that the machine works properly before investing in any extra accessories or features. This means taking the time to thread the machine and check for any signs of wear or damage. Doing so will help to make sure that the machine is in good condition and will work the way that sewers need it to.

Safety Tips for Working with Sewing Machines

Working with a sewing machine requires a certain level of safety awareness. Sewers should always make sure to keep their hands away from the needle and to unplug the machine before making any adjustments. It is also important to keep a clean worksurface and to keep hands and clothing away from moving parts of the machine. Sewers should also not wear anything that could get caught in moving parts and keep their hair tied back away from the machine.

The most important safety concern when working with a sewing machine is the possibility of a needle breaking or coming loose. In these cases, it is important to not touch the needle and to shut off the machine immediately. It is also important for sewers to check for any nicks or damage to the needle before each use and to replace the needle or the entire machine if there are any signs of damage.

Another safety tip for working with sewing machines is to keep the machine in proper working order. This means cleaning and oiling the machine periodically and taking the time to replace any broken or worn parts. Sewers should also be sure to read the manual and become familiar with how the machine works as doing so can help to prevent any accidents.

Overall, it is important for sewers to keep safety in mind when working with sewing machines. Taking the time to read the manual and familiarize themselves with the machine can help to reduce the chance of any accidents occurring. Sewers should also keep the workspace clean and clear of any tripping hazards and take their time when making any adjustments to the machine.