If you find that a needle has broken inside your sewing machine, don’t panic! With a little patience and a few simple tools, you can remove the needle and get your machine back up and running.

If you have a broken needle in your sewing machine, there are a few ways to remove it. The first is to use a pair of needle-nose pliers to grab the needle and pull it out. The second is to use a needle threader to push the needle through the fabric and then pull it out. The third is to use a seam ripper to carefully cut through the needle and then pull it out.

How do you remove a broken sewing machine needle?

If a needle falls inside your sewing machine, don’t panic! Just follow these simple steps to remove it:

1. Turn the machine off

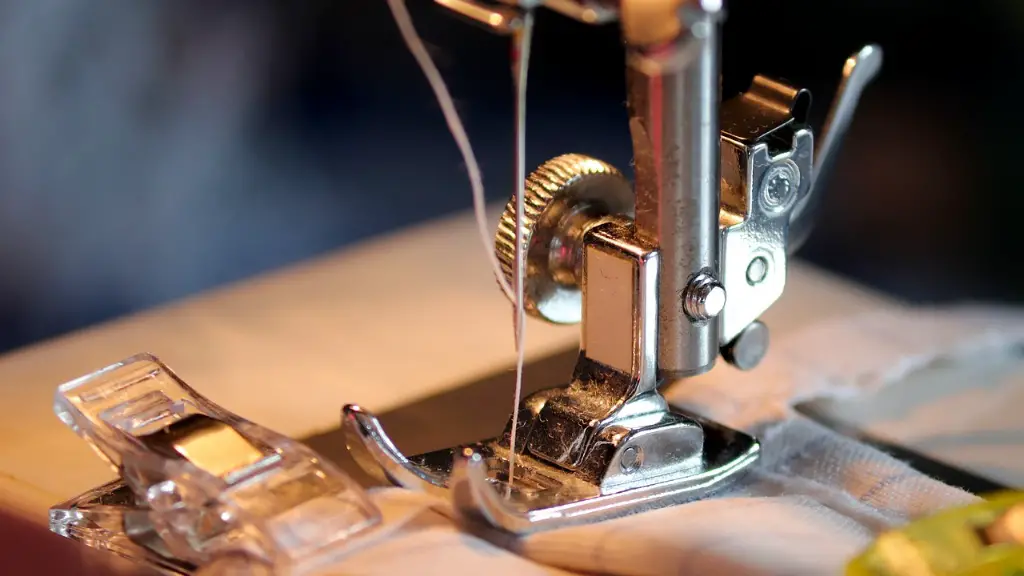

2. Remove the presser foot and presser foot holder

3. Remove the needle plate cover

4. Remove the bobbin case

5. Remove the needle plate using the included disc-shaped screwdriver to loosen the two screws on the needle plate

You should now be able to see the fallen needle and remove it. If you can’t see the needle, you may need to remove the throat plate (the metal plate beneath the needle) to access it.

If the needle is jammed, the first thing you should do is turn the power off. Then, turn the pressure adjustment screw at the top left of the machine to the left to release pressure on the pressure foot. Next, loosen the screw securing the pressure foot to the pressure bar and try to remove the pressure foot from the machine.

What to do if a needle breaks off in you

The patient should be instructed to keep their mouth open and not to move in order to avoid dislodging any dental fragments. The hand that is retracting the soft tissues should be kept in place. If the fragment is visible, it can be retrieved with a haemostat. If the fragment is not visible, DO NOT attempt any incision or probing as this could cause further damage.

If you think your sewing machine needle is broken, there are a few things you can do to check and see. First, check the timing. If the machine is not forming a stitch, the timing is probably off and you will need to get it fixed. Second, make sure you recover all parts of the needle. Even a tiny broken point can become lodged in the wrong place and keep the machine from working properly.

How do you get a broken needle out of a ball?

If you have a ball that is fully inflated, you can then push it and deflate it. This is a great way to save money on your ball.

And place the end of it into the needle clamp screw lightly hold the needle with your left hand and twist the needle clockwise to screw it in.

How do you get a needle out?

It is important to use only one hand when inserting the needle into the cap and remove the covered needle as this can help prevent accidental needle sticks.

There’s a screw up here on the top that needs to be tightened. Once you do that, you’ll have better access to your needle.

How do you remove a needle

To change a needle on a sewing machine, first loosen the needle set screw. Then pull the needle downwards and out of the needle bar. Insert a new needle, making sure that the flat side is facing towards the back of the machine. Push upwards until the butt of the needle hits the stop.

If you accidentally puncture your chest with a sewing needle, don’t panic. Although it’s a rare occurrence, the probability of the needle migrating is very high due to the chest’s high dynamics and mobility. Therefore, it’s important to seek medical attention as soon as possible so that the needle can be removed and you can be monitored for any complications.

How common is needle breakage?

Needle breakage is typically a complications of inferior alveolar nerve blocks. However, it is uncommon for this to happen and usually only occurs when using inferior quality needles. If you do experience a needle breakage, be sure to seek medical attention as soon as possible.

Sewing needles are ferromagnetic, meaning they are attracted to magnets. However, they are not magnetic themselves, so they will not stick to a magnet if you try to put them on one.

Is it easy to replace sewing machine needle

There are a few things you need to keep in mind when changing your needle:

– Make sure you have the correct size needle for your machine. Using a needle that is too big or too small can damage your machine.

– Be sure to insert the needle properly. If it is not inserted correctly, it can cause skipped stitches or fabric damage.

– Be careful not to touch the sharp point of the needle.

– Use proper storage for your needles to prevent them from becoming damaged.

The main hazards for sewing machine workers are needle and driving mechanism injuries. The needle can cause puncture wounds or cuts, while the driving mechanism can result in lacerations or crush injuries. The long line mechanism driving the foot can also cause injuries to the hip, knee and ankle. In particular, the ankle can be twisted, resulting in a lateral ligament injury.

How do you remove a stylus needle?

To clean your record player stylus and improve sound quality, follow these steps:

1. Cartridge, Stylus, Headshell: Identify the stylus (needle housing) on the headshell and gently remove it from the cartridge by wiggling it carefully. Locate the tonearm weight located at the base of the headshell. Use a Phillips #0 screwdriver and remove the screws to free the cartridge.

2. Clean the Headshell: Using a soft cloth, gently wipe away any dirt or dust from the headshell and the connecting wires. Be careful not to touch the needle itself.

3. Clean the Stylus: Use a soft brush or cotton swab to remove any dirt or debris from the stylus. Be careful not to touch the needle itself.

4. Reassemble: Replace the stylus in the headshell and screw it in place. Replace the tonearm weight and screws.

5. Test: Play a record and see if the sound quality has improved. If not, repeat the steps above.

Needles can be scary, especially if you have a fear of them. But there are ways to help ease your anxiety and make the experience a little better. Try to distract yourself while you’re waiting, focus on taking deep breaths, and cough if you need to. Relaxing your arm will also help.

Final Words

If the needle is broken and still in the sewing machine, you will need to remove it before you can continue using the machine. To do this, first unplug the machine from the power source. Then, using a pair of needle-nose pliers, gently remove the broken needle from the machine. Once the needle is removed, you can dispose of it and continue using the sewing machine.

The following are a few tips on how to get a broken needle out of a sewing machine:

-Remove the sewing machine’s needle plate

-Use a pair of needle-nose pliers to remove the broken needle

-Be careful not to damage the machine’s needle shaft

-Replace the needle plate and re-thread the machine