Sewing machines are a great way for hobbyists and professionals alike to expand their knowledge and skills when it comes to making beautiful garments and items. These machines can be complex and intimidating when it comes to changing needles and knowing how and when to do it. There are a few things to keep in mind when it comes to changing the needle on your Singer sewing machine.

The first thing to consider is the importance of safety when it comes to changing the needle. Make sure the machine is unplugged and that all thread has been removed. It is also a good idea to have a cotton swab, a pair of tweezers, and a needle threader, as well as a few other tools on hand.

Pull the needle threader through the eye of the needle, making sure to remove any lint or debris that is present. Use a pair of tweezers to pull the needle out of its current slot; take care not to press too hard on the needle, as this could damage the machine. Once the new needle is in place, slide the needle threader back into the needle slot and thread it through one of the eye holes, then pulle the thread through the two loops of the threader to secure the new needle.

The next step is to adjust the needle position and tension. To adjust the needle position, use the screwdriver to turn the machine’s tension dial. The correct needle tension should be determined by reading the instructions in the manual for your particular sewing machine, or by contacting a sewing machine repair service for advice.

After the position and tension of the needle have been adjusted, it is important to make sure that the needle is in the correct position. The tip of the needle should point straight up, and should be lined up with the horizontal line on the slide plate. If the needle is not lined up correctly, it could damage the fabric or the machine itself.

Before starting a new project, it is also a good idea to test the needle by sewing a few stitches. This will give you a chance to ensure that the needle is inserted and adjusted properly and that the tension is correct before proceeding with your project.

Tips on how to maintain the needle

After changing the needle, it is important to remember to regularly clean and inspect it. Needles which are worn or damaged can cause damage to fabric or machine, and can also lead to frustration while sewing. A good way to maintain needles is to periodically wipe them down with an old cloth or cotton swab.

If a large number of needles have been used and inspected, it is also a good idea to purchase a new set. Needles will become dull over time, which can cause fabric to snag or not evenly stitch. purchasing a new set of needles can extend the life of the needles and maximize the quality of the stitches.

It is important to be aware of how often you need to change and maintain your needles. If a needle breaks or becomes dull, it will need to be replaced immediately.

How to sharpen a needle

Needles can become dull over time and it is important to sharpen them to get the best results from sewing projects. The best way to sharpen a needle is to use an industrial needle sharpener. These sharpener devices will grind and sharpen the needle to be as sharp as a new needle.

Alternatively, it is also possible to sharpen a needle manually. This can be done by rubbing the needle on a piece of fine sandpaper. This process should be done carefully to make sure that the needle is not damaged.

When sharpening a needle manually, it is important to make sure that the needle is aligned properly. The needle should be held at a 45° angle when it is being sharpened to make sure that it is as sharp as possible. It is also a good idea to rotate the needle between each stroke to avoid creating any gouges in the needle.

Advantages of using the correct needle type

When selecting a needle for a specific project, it is important to consider the fabric used and the type of thread used. Choosing a needle that is the wrong size and type for the fabric or thread used can cause frustration and difficulty when sewing and can also lead to uneven stitches and poor results.

It is advisable to always use the correct needle type for each project. This will ensure that the needle is up to the task of stitching the chosen fabric, and will help to prevent any damage to the fabric or needle.

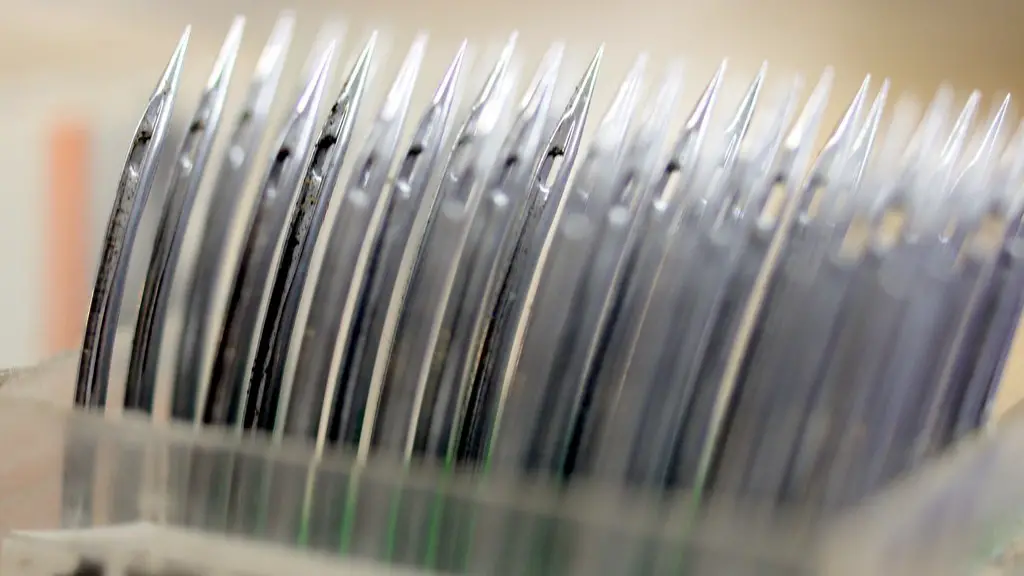

Needles come in a variety of sizes and types, and it is important to understand which one to use for each project. The size of a needle is measured according to its diameter, with larger needles being thicker than smaller needles.

In addition to the size of the needle, the type is also important. The type of needle can affect the overall appearance of stitches and should be chosen based on the type of fabric and thread being used.

Other needle maintenance tips

It is also important to remember to change needles often to avoid undue strain on the machine. Sewing machines are designed to be used with needles for a maximum of eight hours before needing to be replaced, so it is important to keep track of how long each needle has been used.

It is also important to make sure that the needle is correctly threaded each time before use. If the thread is not correctly threaded through the needle, it can lead to poor stitching or damage to the fabric.

Finally, it is important to be aware of the dangers of improper needle use. Needles can be dangerous if not used correctly and should never be inserted or removed while the machine is powered on.

Summary of key points

Here is a summary of the key points to consider when changing the needle on a Singer sewing machine:

- Ensure safety by unplugging the machine and removing the thread.

- Gather the appropriate tools and adjust the position and tension of the needle.

- Test the needle before beginning a new project.

- Periodically clean and inspect the needle.

- Choose the correct needle type for each project.

- Replace needles every eight hours of use to avoid strain on the machine.

- Be aware of the dangers of improper needle use.

Conclusion

In conclusion, changing the needle on a Singer sewing machine can be a daunting task for some. By following the steps outlined above, however, the process can be made much easier and safer. By taking the appropriate safety measures, selecting the correct needle type, and regularly cleaning and inspecting the needle, it is possible to ensure that the machine will remain in good condition and that the results of the project will be of the highest quality.