Sewing is a craft that requires knowledge, expertise and patience. Knowing the basics of sewing—from selecting fabrics to picking the right needle for your sewing machine—will ensure that your project turns out the way you wanted it to. Choosing the right needle for your sewing machine is a must for excellent results. The size, type and shank of the needle are all important factors to consider when making your selection.

Size – The size of needle used is directly related to the fabric you choose. Thin fabrics, such as chiffon, require a small needle, such as size 9 or 10. Medium-weight fabrics, such as calico or linen, require a larger needle, size 11 or 12. Heavyweight fabrics, such as denim or canvas, require a large needle, such as size 14 or 16. The general rule of thumb is the heavier the fabric, the larger the needle.

Type – Depending on the type of project you’re working on, you may need a different type of needle. Universal needles are the most common and are used for most fabrics. Denim needles are designed for tough fabrics such as denim and will help you achieve a smooth, even stitch. There are also quilting needles, which are designed for fabrics with multiple layers, such as quilting, pique and fleece. Ballpoint needles are specifically made for knit fabrics and are designed to push aside the fibers of the fabric instead of piercing them, reducing the risk of snagging and breakage.

Shank – Sewing machines have different types of needle shanks, such as flat or rounded. Depending on the model of your sewing machine, you may need a particular type of shank. Be sure to check the manual of your machine to determine the right shank size needed. For example, a flat shank may be necessary for machines with a horizontal hook, while a rounded shank may be needed for machines with vertical hook.

For best results, it’s important to choose the right needle for your sewing machine. Sewing machines vary, so make sure to read your machine’s instructions to determine the type and size of needle you need for your project. When in doubt, opt for a universal needle to ensure that it’s compatible with your machine and will work for most fabrics.

Types of machine needles

When it comes to choosing a needle for your sewing machine, there are a few different types to choose from. Universal needles are the most common and can be used for most fabrics. Ballpoint needles are specifically made for knit fabrics and are designed to push aside the fibers of the fabric instead of piercing them. Denim needles are designed for tough fabrics, such as denim and canvas, and will help you achieve a smooth, even stitch. There are also quilting needles, which are designed for fabrics with multiple layers, such as quilting, pique and fleece.

Also, take into consideration the brand of the needle and choose one that is high quality and of good reputation. Cheap needles may be tempting to buy, but they are more prone to breaking and can cause more damage to your fabric. Many manufacturers offer a variety of specialty needles and are designed for specific tasks such as topstitching, quilting and embroidery.

How to choose the right size needle

The size of needle used is directly related to the fabric you are using. Thin fabrics, such as chiffon, require a small needle, such as size 9 or 10. Medium-weight fabrics, such as calico or linen, require a larger needle, size 11 or 12. Heavyweight fabrics, such as denim or canvas, require a large needle, such as size 14 or 16. The general rule of thumb is the heavier the fabric, the larger the needle. It is best to use the smallest needle size that will accommodate the thread you are using.

For examples, if you are using a lightweight thread, use a smaller needle size regardless of the weight of the fabric. A lightweight needle size combined with heavy-duty thread can cause skipped stitches and an uneven stitch. It is also important to use the correct-sized needle for the type of material you are sewing. Heavier fabrics like denim require a larger, stronger needle.

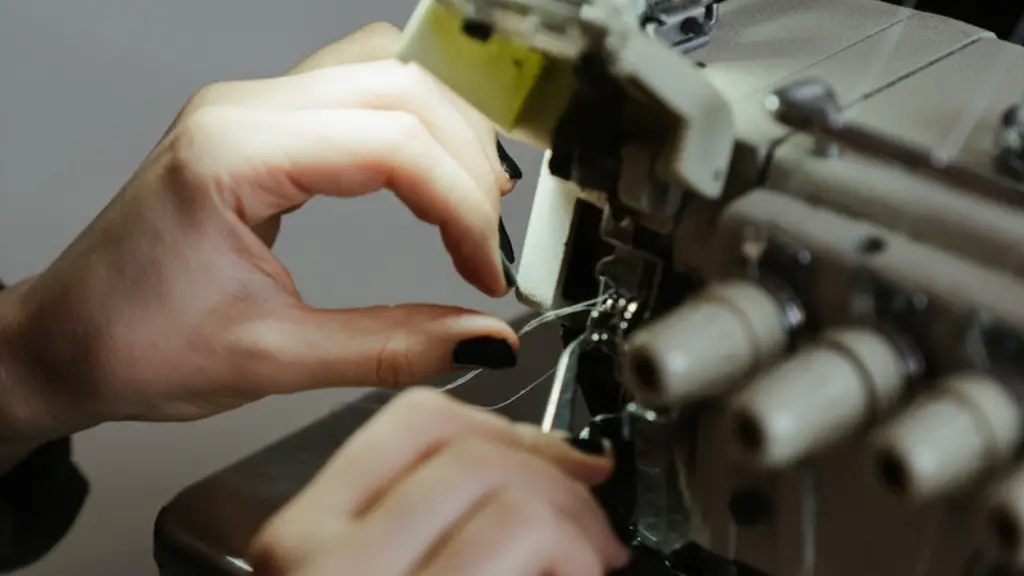

Needle Bent and Overlock

Bent needles are designed to help sew difficult fabrics and recline seams. Bent needles are useful for sewing fabrics such as leather and vinyl. Bent needles are shorter and have a curved design to make it easier to maneuver the needle while sewing. Overlock needles are similar to bent needles but have a thicker shaft and a sharper point.

Overlock needles are designed specifically for stitching overlock or serger seams. They are also useful for sewing fabrics such as leather, suede and other heavy fabrics. Overlock needles can also be used for a variety of decorative stitches such as pintucks and piping.

Needle change

It is important to change your needle frequently to ensure that you don’t cause damage to your fabric. Universal needles should be changed approximately every 8 to 10 hours of use. Heavier needles for fabrics such as denim should be changed even more often. Using a dull needle can cause skipped stitches, uneven stitches, and fabric damage, so it’s important to make sure your needle is in good condition.

To ensure that you have the best results, it is important to use a fresh, sharp needle for each project. Needles can become dull quickly, especially if you are using a heavier fabric. Changing your needle regularly will help to prevent fabric damage and skipped stitches.

Testing needles

When working with a needle, it is important to run a few tests before you start working on your project. You can test the needle by placing it on a piece of scrap fabric and attempting to stitch. If the needle is too small, it will cause skipped stitches or thread breakage. If the needle is too large, it will cause fabric to bunch and create uneven stitches.

If you are finding that the needle is causing thread breakage, then it is time to buy a new needle. It is also important to test the needle for sharpness. Run your finger lightly across the point of the needle. If it feels rough, it is time to replace it.

Needle Point Maintenance

Once you’ve selected the right needle for your project, it’s important to keep the needle point in good condition. The needle point can be worn down over time. To keep it sharp, make sure to unthread your machine every time you finish a project and store the needle carefully. Additionally, do not use a heavy hand when pushing the needle through fabric. If you need to apply more pressure, adjust the tension on your sewing machine.

It’s also helpful to use a thread conditioner, such as beeswax. This helps to lubricate the thread and reduce friction, allowing the needle to glide more smoothly through the fabric and reduce the risk of wear on the needle point. If a needle becomes worn down and cannot be salvaged, discard it and replace it with a new needle.

Conclusion

Choosing the right needle is essential for successful sewing projects. Select a needle that is compatible with your sewing machine, the right size for the fabric, and the right type for the task. Change your needles often, keep your needle point sharp and use thread conditioner to reduce friction while sewing. Once you know the basics of needles and fabric, you’ll be able to create beautiful and unique projects with confidence.