Maintaining a clean sewing machine is essential for seamstresses and tailors. Sewing machines must be kept free from lint, dust, pet hairs, hairspray and other debris to continue working effectively. If debris accumulates on the machine, it can cause the machine to jam and even cause permanent damage. It is therefore important to carefully clean it with the help of a specialist. This article provides a comprehensive guide to cleaning a sewing machine to ensure it is functioning safely and properly.

Firstly, it is important to remove any visible debris or loose lint from the body of the machine. A soft, lint-free cloth should be used and gently wiped across the body. This can effectively remove surface dust and dirt, making it easier to proceed with a deeper clean.

If the machine is badly stained with grease or oil, it is best to consult a specialist. Grease build-up can cause permanent damage and should be handled by a professional.

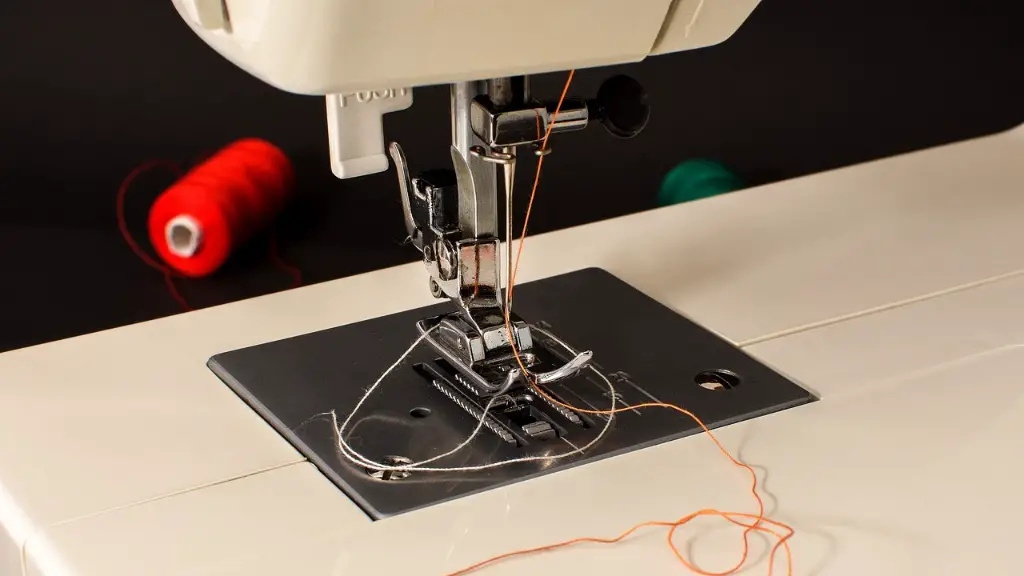

Secondly, the area around the bobbin compartment should be brushed to get rid of any lint which may have become lodged in the feed dogs or any other areas. This can be done using an upholstery brush or an air can filler.

Thirdly, the machine should be oiled to keep it running efficiently. This should be done using only special oils made for sewing machines– never use general lubricants as this could damage the machine. The manufacturer’s instructions should be followed to ensure the oil is correctly applied.

Fourthly, the needle should also be checked and changed if necessary. If the needle is bent or nicked, it should be changed to ensure it is not damaged further. The needle should be changed after every five hours of sewing.

Finally, the machine should be thoroughly wiped down to avoid any dust settling on the surface. It is best to use a lint-free cloth and polish with a thin layer of paste wax to protect the finish of the machine.

Safety Precautions to Take

Safety is always paramount when cleaning sewing machines. It is important to unplug the machine from the power source before attempting to clean it, as even the slightest contact with electricity can cause damage to the machine or even cause shock.

When cleaning the interior, it is important to avoid using chemicals or any other abrasive materials. Always opt for a soft, lint-free cloth to avoid damaging the delicate parts of the machine.

When oiling the machine, it is important to follow the manufacturer’s instructions on the type of oil to use and how much to apply. Over-oiling can cause oil leakage which may damage other parts of the machine.

Finally, it is also important to check the belt and tension wheel for any signs of wear and tear, as this could cause further damage if left unchecked.

Consulting a Professional

Depending on the type, frequency and intensity of use, it is often necessary to call a professional to inspect and service a sewing machine. A professional sewing machine technician will be able to inspect, adjust and calibrate your machine as well as provide advice on troubleshooting and preventative maintenance.

If any repairs are required, a professional can also determine if it is cost-effective to repair or replace the machine. This can save you time and money in the long run.

This is especially important for older machines, as they may require spare parts which are difficult to find on the market. A professional technician can also identify potential problems with the machine and offer solutions or recommendations.

Conclusion

In conclusion, it is necessary to keep a sewing machine clean and well maintained to ensure its longevity and performance. Taking simple steps such as regularly cleaning the machine and ensuring the needle is changed regularly will ensure the machine is functioning optimally. Furthermore, where necessary, it is important to consult a professional technician for advice and repairs. Following these tips will help extend the life of the sewing machine and save time and money in the long run.

Keeping Parts Clean and Sanitized

Sewing machines contain many parts that should be kept clean to avoid any cleaning related issues. The foot pedal, for instance, transmits electricity to the machine and should therefore be kept lint-free and free from debris to ensure the machine is properly functioning. The belt should also be checked for any signs of wear and tear and the tension wheel should be regularly adjusted.

Sanitizing the machine is also important, especially if it is used by multiple people. A mild solution of soap and water should be used to clean the exterior of the machine and a cloth soaked in rubbing alcohol can be used to sanitize the machine.

It is also important to always wear protective gloves and face masks when cleaning machines. This will protect against any dust particles or hazardous materials which could affect health.

Preventative Maintenance

There are simple steps that can be taken to ensure sewing machines stay in good condition and offer optimum performance. Regularly checking the needle threader and tension wheel, for example, will ensure the machine remains running smoothly.

In addition, the machine should be kept away from extreme temperatures and direct sunlight. Heat and sunlight can cause plastics to become brittle and wear down easily. It is also important to keep the machine covered when not in use.

Any dust build-up should be removed with a vacuum or a soft, lint-free cloth. Vacuuming is often better as it can pick up finer dust particles which cannot be removed with a cloth. After vacuuming, the machine should be wiped down with a clean and dry cloth.

Oiling the machine is also important and should follow the manufacturer’s instructions. Applying too much oil can cause oil leakage which could damage the machine further, so it is important to take care when oiling.

Storing the Machine

Sewing machines should always be kept in a dry and clean space, away from extreme temperatures and direct sunlight. Humidity and heat can cause plastics to easily become brittle, so it is important to store machines in a cool and dry environment.

As mentioned above, the machine should always be covered when not in use. This will help ensure the machine is protected from dust and dirt while in storage. It is important to opt for a breathable cover, as this will ensure any moisture is kept away from the machine, avoiding the risk of rust.

Moving the machine can be difficult and it is important to tilt the machine and hold it securely to avoid any damage. It is best to avoid lifting the machine as this could cause the internal workings to become unbalanced. It is also important to use two people to transport the machine, as this will reduce the risk of dropping or mishandling.