Tools Needed

When it comes to knowing how to clean and service a sewing machine, having the right tools on hand can make all the difference. While some materials are machine-specific, the most commonly used tools include a screwdriver, small soft brush, vacuum, tweezers, and a needle-nose pliers. It’s important to use the appropriate size tools that are designed specifically for sewing machines, as the wrong tools can damage or strip any screws or delicate parts.

Remove Exterior Dust and Debris

Before getting into any of the internal workings of the machine, it’s important to take care of the exterior. Oftentimes, sewing machines can gather a lot of dust and debris as a result of surface wear and tear and fabric fibres, which can work its way inside the machine and cause problems in the long run. Start by unplugging the machine and giving the outside surface a quick wipe down with a lightweight microfiber cloth. This will help to remove any dirt, lint, and surface fibers from the casing. To get into tight nooks and crannies, a small brush can often come in handy. In addition, use a vacuum cleaner to clean any remnant fibers from fan blades and buttons.

Inspect and Clean the Bobbin

The bobbin is one of the most critical parts of any sewing machine, so it’s important to inspect and clean it regularly. To clean the bobbin, use tweezers to pick out any lint or particles that may have gotten stuck in the threading grooves. Keep in mind not to damage or bend the bobbin spring when doing so. It’s important to note that the bobbin spring should not be cleaned or lubricated as this can impair its function. In addition, it’s important to make sure the bobbin is winding evenly and its tension has been properly adjusted. If not, the machine may fail to sew properly or produce a weak or looped stitch.

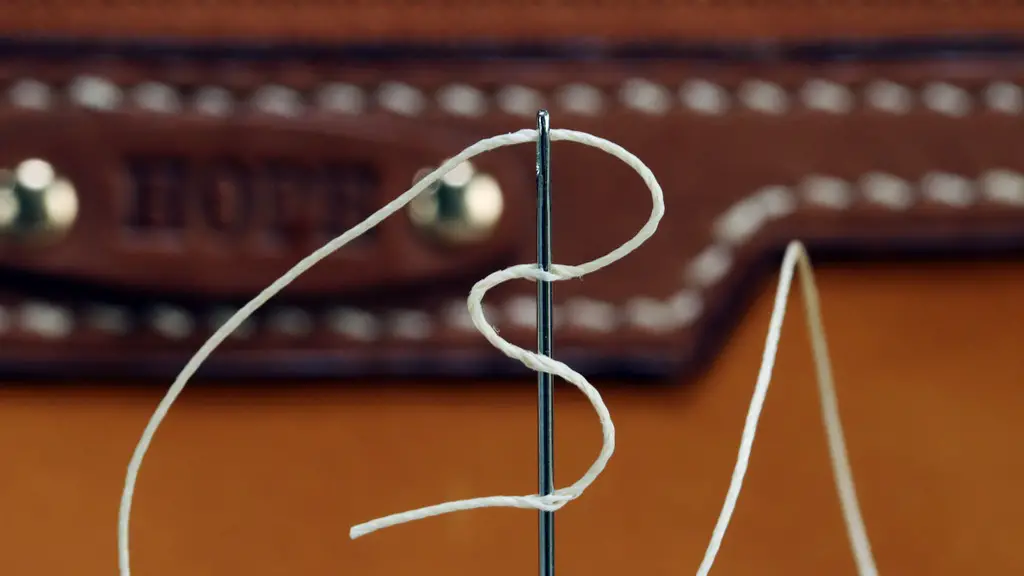

Disassemble and Clean the Hooks

The hook of the machine is responsible for looping the thread from the bobbin above the fabric, which creates the desired stitch. To ensure the hook is operating efficiently, it must be disassembled and cleaned regularly. To do so, make sure to unplug the machine, then carefully remove the bobbin holder and hook. Once the hook is appropriately cleaned of any debris, use a tiny paintbrush to carefully apply a drop of sewing machine oil to any metal surfaces that come in contact with the thread or needle. It is important to note to not over oil or apply too much oil around the hook.

Lubricating the Machine

Regardless of the type of sewing machine, lubricating the moving parts is essential for optimal operation. To do this, use a sewing machine oil that is specifically made for your model. Start by unplugging the machine, then use a drop cloth to cover the base and make sure that oils don’t get on any of the fabrics. Use the oil in spray form for larger parts such as the feed dog and presser foot lever, as this can help from leaving any excess oil near delicate mechanisms. For the smaller parts, use an oil dispenser or small needle oiler. These provide precise control to make sure the oil is applied to only the desired areas.

Test the Machine

Once the machine has been serviced, it is important to give it a test run to ensure that the moving parts are operating correctly and that everything is running as it should. Make sure to attach an appropriate fabric sample and sew through it at different speeds and tension settings to identify any discoloration, tangling, or weaknesses. In addition, pay attention to any odd noises or movements and make sure that the machine is running at full speed.

Adjustments and Repairs

Aside from cleaning, it’s important to make sure that your sewing machine is regularly adjusted and repaired. If the machine is not working properly and showing signs of wear and tear, it’s essential to have it serviced by a professional technician before any further damage is done. A qualified technician can easily identify any issues that may have been overlooked, such as damaged parts or incorrect tension settings, and can make any necessary repairs.

Care and Maintenance

Perhaps the most important step when it comes to cleaning and servicing a sewing machine is proper care and maintenance. This includes regular cleaning and lubrication, as well as following basic maintenance protocols as recommended by the manufacturer such as keeping the machine covered when not in use. Just like any other machine, sewing machines require regular upkeep and maintenance to ensure optimal performance and longevity.

Carrying Out Repairs Yourself

In some cases, it may be possible to carry out some of the repairs on your own. Always use caution when handling delicate elements as it is easier to inadvertently damage the sewing machine than it is to repair it. Common repairs that can be carried out on your own include replacing thread, needles, and bobbin cases, as well as checking and adjusting the tension, feed dog, and presser foot.

Using the Right Fabrics and Threads

The fabrics and threads you use can make a significant difference on the quality, speed, and efficiency of your machine. Choose the right variety of fabrics and threads for the project you are working on as heavier fabrics can place a strain on the motor and also cause the machine to move slowly. In addition, always use high-quality threads, as they will result in fewer broken needles, less tension problems, and fewer skipped stitches.

Keep the Machine Covered and Protected

When not in use, make sure the sewing machine is covered up and protected from the dust, dirt, moisture, and extreme temperatures. Investing in a high-quality cleaning cover is recommended as this will help keep the machine protected and ensure that it lasts for many years to come.

Educate Yourself

The best way to learn how to use and maintain a sewing machine is to educate yourself. There are a variety of books, videos, and online resources available that can provide helpful information about cleaning, servicing, and repairing a sewing machine. Taking the time to read up on the subject and learning the basics of operating a sewing machine can go a long way towards ensuring long-term satisfaction with the machine.