It can be a daunting task to find the ¼” of a seam on a sewing machine. However, it doesn’t have to be overwhelming. With some attention to detail, precision and patience, anyone can measure the right width on a sewing machine.

To begin with, before commencing any sewing project, it is important to ensure that the machine is set up correctly. This includes ensuring that the needle is installed correctly, in the appropriate size and style, and that the sewing machine is threaded properly.

It is also important to note that many modern day machines come with a ¼” seam guide; this guide is a great tool for finding the correct width of a seam. It should be aligned with the needle for accurate results. If the sewing machine does not possess this feature, it will be necessary to measure the seam by hand. To do this, use a regular ruler and line up the ruler with the metal plate on the bottom of the machine.

It is also important to use the appropriate needle size for the fabric being used. A smaller gauge needle, such as an 80/12 or 70/10, is best used for lightweight fabrics such as sheers or chiffons, while a larger gauge needle, such as a 90/14 or 100/16, is best used for heavier fabrics like denim or canvas.

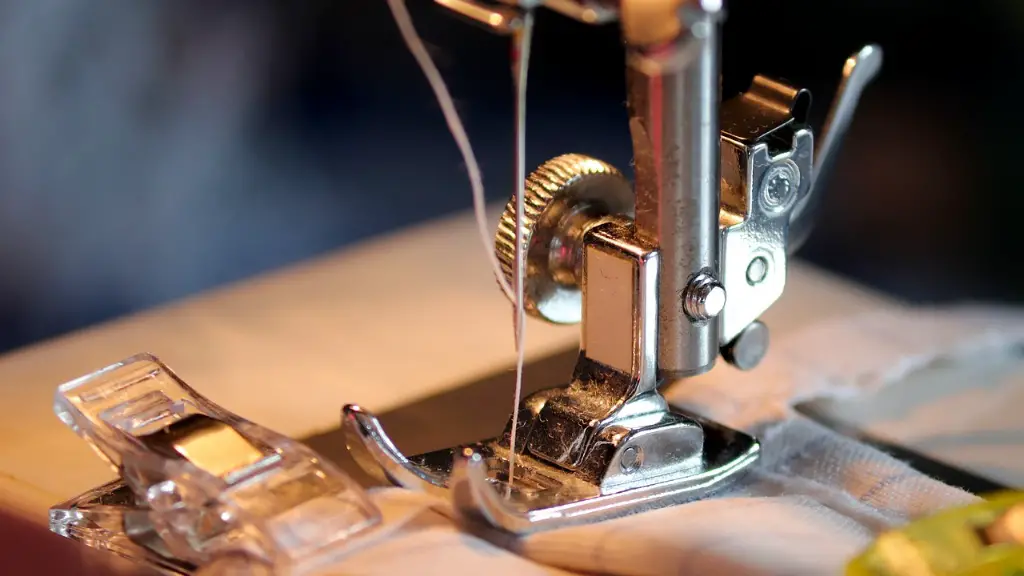

In addition, it is critical to ensure that the presser foot is set correctly. A standard foot should be used when constructing most garments, while a zipper foot or rolled hem foot should be used when hemming or installing a zipper. The correct foot will provide a more precise, professional looking result.

Finally, the seam allowance should not be neglected. A seam allowance of ¼” is usually standard for most garments; but when working with lightweight fabrics, a thinner seam allowance of 3/16” may be necessary. To make sure that the seam allowance is accurate, a tailor’s ruler can be used to measure the width of the seam, and then the machine should be adjusted accordingly.

Using Tools for Accuracy

Advanced tools are available to ensure precision when sewing, such as seam guides and special presser feet. Seam guides have markings at ¼”, 3/8” and 5/8” increments, and can be placed at the needle plate post or next to the feed dog. Special presser feet are also available, such as the quarter inch foot, which allows for easy and accurate ¼” seams.

In addition, specialty rulers can be used to accurately measure seam allowances. These rulers come in a variety of sizes, from ¼” to 1”. Most rulers also have a built-in grid that is helpful when measuring multiple seam allowances.

Finally, using a tailor’s ham is an effective way to help ensure seam accuracy. A tailor’s ham is a stuffed and stiffened ham-shaped cloth form, which is used to press seam allowances. It forms a nicer shape, and helps to ensure a neater seam.

Tips for Locating the ¼ inch

When working on a sewing machine, it is often helpful to have an understanding of the features. The needle post should be lined up with the ¼-inch mark on the needle plate. This makes it easier to locate the ¼ inch accurately and quickly as you work.

Also, it is important to remember that ¼ inch seam allowances are universal. This means that when constructing most garments, it is always a ¼ inch measurement, no matter the type of fabric. For example, when sewing a shirt, the armholes should be sewn with a ¼ inch seam allowance, regardless of the fabric weight or type.

Finally, it can be helpful to draw guidelines on the fabric itself, as a visual aid. Draw a ¼” line on the wrong side of the fabric with markings, such as a ruler, that delineates the seam allowance. This provides a visual aid to ensure accuracy as well as a helpful time-saver.

Pressing Seams

Another key factor in finding the ¼ inch seam on a sewing machine is ensuring that the seam allowances are pressed properly. Ironing after each seam helps fabric to lay flat and neat. Additionally, use a tailor’s clip to ensure that the seam allowance is the specified width. Tailor’s clips are especially helpful when dealing with uneven seams.

Prior to pressing, it is recommended to take the time to test the temperature setting on scraps of fabric first, to make sure that the fabric does not get damaged; when in doubt, steam only. Furthermore, use a pressing cloth for more delicate fabrics to prevent scorching. Be sure to press the seam allowances to the correct side of the garment; this will help make sure that the seam allowances are even and will help the seams lay flat.

Finally, when pressing multiple layers of fabric, use a clapper or a wooden rolling pin to ensure that the seam is pressed flat and crisp. These small tools are an invaluable addition to any sewing supplies.

Taking Measurements

When using a measuring device to confirm the ¼ inch seam width, there are a few important steps to follow. First, it is important to make sure that the symbol or line is aligned with the needle. This will ensure the ¼ inch seam is accurate. Additionally, be sure to take the measurement from the base plate where the needle post is located.

Also, to ensure consistency and accuracy, it is essential to check the seam frequently with a measuring device, such as a ruler or a tailor’s measuring stick. This is of particular importance when dealing with multiple seams in the same project.

Finally, when working with a new sewing machine, it is essential to double check the seam allowance to make sure it is correct. A quick and easy way to do this is to sew an inch of the seam and measure. This will help to ensure accuracy and will help to avoid any chance of errors in future projects.

Getting Familiar with the Machine

Finding the ¼ inch seam on a sewing machine requires practice and getting familiar with the machine. By familiarizing yourself with the features of the machine, and understanding the importance of accuracy and attention to detail, anyone can easily and quickly find the ¼ inch seam.

In addition, it is important to take the time to perfect the technique and practice regularly. This will help to ensure accuracy and precision on future projects, not only in terms of seam allowance, but also in terms of quality. It is also recommended to use a muslin for practicing instead of fabric, as it is more reliable, less expensive and can be used multiple times.

Finally, it is essential to be patient. The ¼ inch seam is not always easy to find, and it will take patience and practice, as well as a keen eye for detail, to ensure success. Although it may seem intimidating, with some patience, practice and attention to detail, anyone can easily find the ¼ inch seam on a sewing machine.