If your needle threader doesn’t seem to be working properly, there are a few things you can check to see if it needs to be repaired or replaced. First, make sure that the needle is inserted correctly into the needle threader. The needle should be inserted all the way into the eye of the needle threader so that the end of the needle is flush with the end of the threader. If the needle is not inserted correctly, the threader will not be able to grab the thread and pull it through the needle.

Next, check to see if the needlethreader is properly aligned with the needle. The needle should be in the center of the needle threader, and the threader should be lined up so that the hook is directly over the eye of the needle. If the needle threader is not lined up correctly, it will not be able to grab the thread and pull it through the needle.

Finally, check to see if the tension on the needle threader is set correctly. The tension should be set so that the thread is pulled tight when the needle threader is inserted into the eye of the needle. If the tension is too loose, the thread will not be pulled through the needle and the needle threader will

There are a few steps you can take to try and fix a needle threader on a sewing machine. First, make sure that the needle is in the correct position and that the shutter is open. Second, check the spring to see if it is intact and in the correct position. Finally, consult the manual for your specific machine to see if there are any other troubleshooting steps you can take.

Why is my sewing machine threader not working?

If you’re having trouble with your automatic needle threader, it could be for any of the reasons listed above. Make sure you’re using the right size needle and type of thread, and that the needle is installed correctly and not damaged or bent. Also check that the hook on the needle threader is not damaged.

If you’re having trouble threading your needle, make sure you’re holding the thread lightly and that the needle is threaded correctly. The needle eye should be threaded from the front to the back.

Why do my needle threaders keep breaking

If your thread keeps breaking, there are a few things you can check:

-Are your needles bent or faulty?

-Is your bobbin case clean?

-Have you adjusted the tension disc?

-Is your throat plate clean?

-Is your thread quality good?

-Do you have any snags or knots in your thread?

If you can check all of these things, you should be able to avoid thread breaking.

If your sewing machine has an automatic threader function, it can be a great time saver! Simply guide the thread through the eye of the needle and let the machine do the work for you.

What is the most common mistake when threading a sewing machine?

If you’re having trouble threading your machine, make sure that the presser foot is in the up position. Many machines will lock the tension disks when the presser foot is down, which can make it difficult to thread the machine correctly.

If the tension on your sewing machine isn’t perfect, you can fix it by adjusting the bobbin spring. If the bobbin thread is showing on the upper layer, you’ll need to tighten the spring. If the needle thread is showing on the underlayer, you’ll need to loosen the spring. Make another test seam, and examine the stitches, repeating the process until the stitch is balanced.

How do you fix a thread jam on a sewing machine?

There’s no need to remove your presser foot when using tweezers—simply pop it off and get out of the way. This will make the process quicker and easier.

If your needle is not inserted properly, the threads can break. Make sure the eye of the needle is facing the front (not slanted) and that the scarf (indent) of the needle is facing the back. Burrs in the needle may also cause the thread to shred. It’s also important to check up on your needles from time to time.

What can I use instead of a needle threader

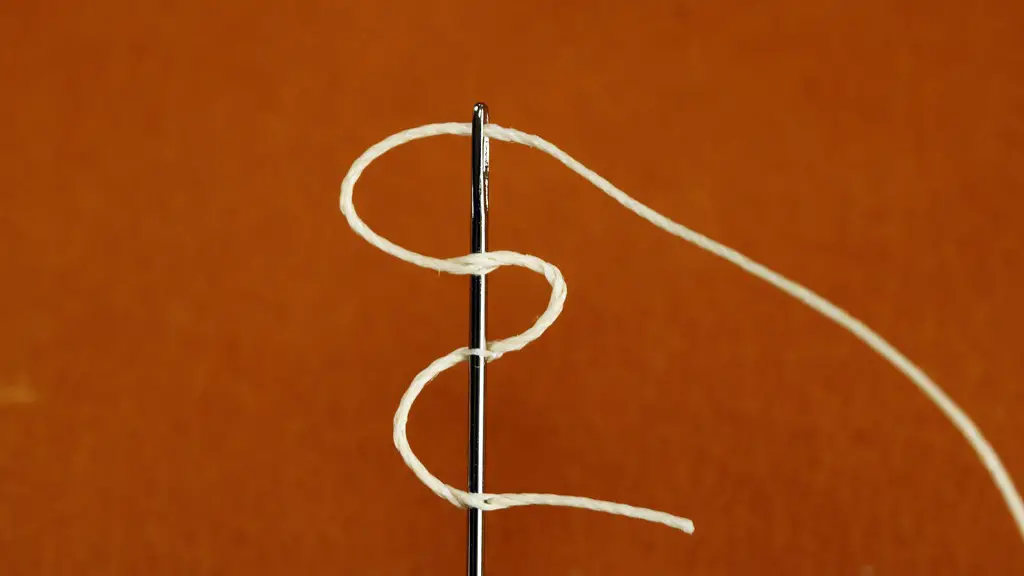

There are a few ways to thread a needle without a needle threader. One way is to fold the thread over the needle and then pull the thread tightly around the needle. Another way is to pinch the thread between your thumb and forefinger and then pull the needle out from between your fingers. Another way is to place the eye of the needle over the thread and then push it down.

If you need to pull the needle out of the fabric, hold it at the ‘bottom’ (opposite of the pointed end) so the thread doesn’t come out. This way the thread can’t go anywhere while your fingers are holding it in place.

How does an old fashioned needle threader work?

You hold your needle threader because sometimes these little metal bits can come out so you hold the threader with your index finger and your thumb. You insert the needle into the eye of the needle threader. You pull the needle threader back out of the eye and the needle should now have thread on it.

This is a basic description of how to thread a needle. First, the user passes the wire loop through the needle eye. Next, the user passes the string through the wire loop. Finally, the user pulls both the loop back through the needle by the handle, which pulls the thread through.

How do you thread an automatic threader on a Singer sewing machine

In order to do this, we’re going to take the thread and slide it up the front of the needle. Once it’s in position, we’re going to pull it a little bit more until the knot is tight against the fabric.

Threading issues are problems that can occur when two or more threads are running at the same time. These issues can include race conditions, deadlocks, and livelocks.

How long do sewing machines last?

Sewing machines that are well-cared-for and used sparingly can last a very long time, while those that are neglected or used excessively may only last a few years. It is important to keep your sewing machine clean and well-oiled to ensure its longevity.

If your sewing machine needs a tune-up, the cost can vary depending on the shop you take it to. Generally, the cost will be in the $75 to $100 range. This does not include the cost of any broken or replacement parts.

Warp Up

If the needle threader on your sewing machine is not working properly, there are a few things you can do to fix it. First, make sure that the needle is properly inserted into the needle threader. Next, check to see if the moving parts of the needle threader are properly aligned. Finally, clean the needle threader with a soft cloth to remove any dirt or debris.

If your needle threader is not working, first check to see if the needle is inserted correctly. If the needle is not inserted correctly, the threader will not be able to work. Next, check to see if the needle is bent or damaged in any way. If the needle is bent, you will need to replace it. Finally, check to see if the guide fingers on the needle threader are bent. If they are, you will need to replace the needle threader.