If you’re experiencing your sewing machine needle hitting the plate, there are a few things you can do to fix the issue. First, check to see if the needle is properly installed. Next, check to see if the needle is the correct size and type for your sewing machine. Finally, check to see if the needle is bent or damaged. If you’re still having trouble, take your sewing machine to a professional for help.

If your sewing machine needle hits the plate, there are a few things you can do to fix it. First, make sure that the needle is properly inserted into the needle clamp. If it is not, then unscrew the needle clamp, insert the needle into the clamp, and screw the clamp back on. Tighten the screw just enough so that the needle is secure, but not so tight that it is difficult to remove. Next, check the needle size and type. The needle should be the correct size and type for the fabric you are sewing. If it is not, then change the needle. Finally, check the tension. The tension should be set so that the needle and thread can move easily through the fabric. If the tension is too tight, the needle will hit the plate. If the tension is too loose, the stitches will be too loose.

Why does my sewing needle keep hitting the plate?

If you’re having trouble with your needle hitting the needle plate, it could be because you have the wrong needle plate on the machine. Make sure you have the right plate for the stitch you’re trying to sew. If everything is in place and the needle is still striking the plate, you’ll need to take it to the dealer to have it fixed. There’s likely something out of alignment.

If the needle is not properly fitted in your machine, it can cause a variety of problems. Make sure to firmly tighten the needle set screw to ensure that the needle is properly secured.

How do you align a sewing machine needle

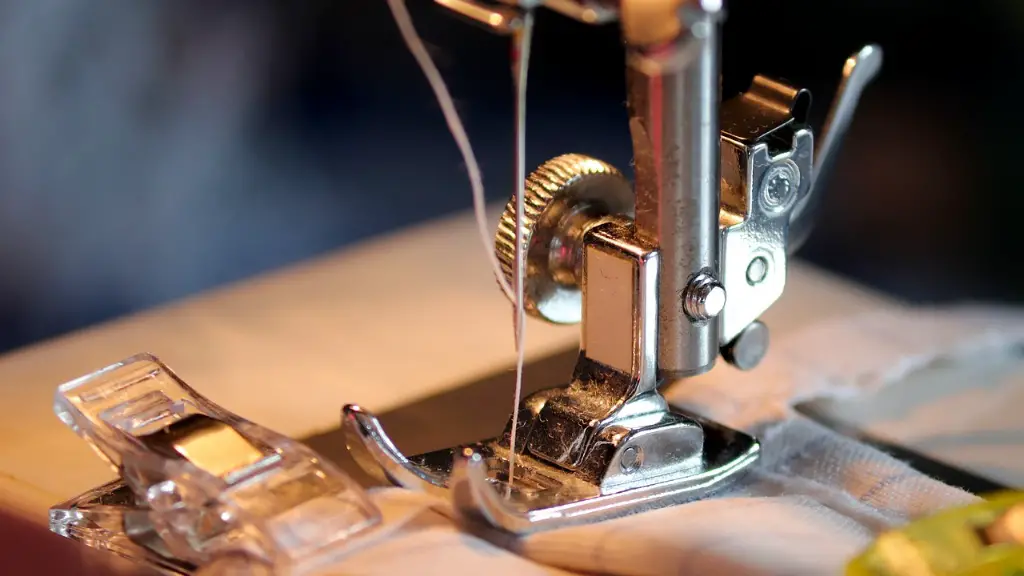

This is your needle board. So right over here that screw you see there, each machine has it. This is what we use to set the needle. And then this is your presser foot, so this is what actually holds the fabric down while you sew.

If your throat plate has been nicked by you sewing over a pin, it will snag the bobbin thread and cause tension problems. Your sewing may look all uneven and certain sections may look caught and looped.

How do I know if my timing is off on my sewing machine?

If your hook tip is passing through or below the needle eye, then the timing of the sewing machine is off. On the other hand, if the hook tip is passing above the needle eye, but extends past the needle more than a couple of millimeters when the needle eye meets the radius of the hook, then the timing is also off.

To remove the needle plate cover on a sewing machine, insert the tip of the index finger of the left hand into the notch at the back of the needle plate cover. Place the thumb of the left hand at the front of the needle plate cover. Slide the needle plate cover toward you to remove it.

How do you fix a needle that hits a bobbin case?

If you’re having difficulty with your sewing machine, there are a few things you can check to see if the issue is with the needle:

-Check that the machine is threaded properly

-Check that the bobbin case is correctly installed

-Check the presser foot

-If you have adjusted the stitch width or length, turn the hand wheel toward you to verify that the needle does not hit the foot or needle plate

But physics is a tricky thing due to the high energy And small size the needle in contact with the record May bend or break without the user’s knowledge.

How do you align a Brother sewing machine needle

The Straight or Triple Stretch Stitch is a versatile stitch that can be used for a variety of purposes. The needle position can be changed from left to right by adjusting the stitch width dial. This allows you to customize the stitch to best suit your needs. To set your needle in the right position, set your stitch width dial to 0. To set your needle in the left position, set your stitch width dial to 5. For normal center position, set your stitch width dial to 2.5.

A smaller needle will sit on the left side of the needle hole, but a larger needle will be more centered. This is normal, as there is no adjustment on the Featherweight for the position of the needle.

How do you set a needle bar?

A Statler machine is a type of quilting machine that is often used in the construction of quilts. The machine is named for its inventor, Elmer Statler.

This is a great feature for precise sewing!

What does a throat plate look like

Throat plates are usually marked with closely spaced, grooved lines to help you guide your seam allowance. The lines are usually different widths to help you vary your seam allowance.

This is a great way to remember how to keep your room tidy. By associating a specific action with a desired outcome, you will be more likely to achieve your goal. In this case, the goal is to keep your room tidy by turning everything to the right.

What is the function of throat plate in sewing machine?

The throat plate is a metal plate on your sewing machine that the needle and presser foot go through to make stitches. There is a small opening in the plate that allows the bobbin thread to come out and the needle to pass through. The throat plate helps to protect your machine from damage and keep your stitches nice and straight.

Improper ignition timing can be caused by a number of things, including changes to the engine, incorrect initial timing settings, or a problem with the timing belt or chain. Ignition timing that is off by even a small amount can cause knocking, hard starting, increased fuel consumption, overheating, and reduced power. If you suspect that your ignition timing is off, it’s important to have it checked by a qualified mechanic as soon as possible.

Conclusion

If your sewing machine needle hits the plate, there are a few things you can do to fix it. First, check to see if the needle is properly inserted. If it is, then check to see if the plate is properly aligned. If it is, then check to see if the tension is set correctly. If the tension is too loose, the needle will hit the plate. If the tension is too tight, the needle will not be able to move properly.

If your sewing machine needle is hitting the plate, there are a few things you can try. First, check to see if the needle is correctly inserted. If it is, then try tightening the screw that holds the needle in place. If that doesn’t work, you may need to replace the needle.