Sewing machines are a necessary tool for many crafters and seamstresses, but they can be frustrating when the needle breaks or falls out. Luckily, it’s not too difficult to fix a broken needle or replace a lost one. With a little patience and a few simple supplies, you can have your sewing machine up and running again in no time.

To fix the needle in a sewing machine, first make sure the machine is unplugged. Next, remove the needle plate by loosening the retaining screw and lifting it off. Then, remove the throat plate by loosening the retaining screws and lifting it off. With the throat plate and needle plate removed, the needle can be accessed. To remove the needle, unscrew the needle clamp and pull the needle out. To insert a new needle, reverse the process. Screw the needle into the needle clamp and then insert the needle into the machine. Make sure the needle is inserted all the way and that the flat side is facing the back. Once the needle is in place, replace the throat plate and needle plate. Finally, plug the machine back in and test it out.

How do you fix a bent sewing machine needle?

If you have a bent needle, don’t worry! You can easily straighten it out with a nickel. Just find a hard, flat surface and use the flat part of the nickel to roll out any bends against the hard surface. Roll the needle around to find the bent part and again press the coin flat against the needle, straightening it. Repeat until the needle is completely straight.

If your machine is not sewing, check to see if the machine is threaded correctly. The threading line on the hand wheel should be at the top position. This will put the needle into the correct position for threading. Make sure the presser foot is lifted before threading the machine. Set your bobbin correctly into the machine.

How do you fix a needle on a Singer sewing machine

Take a new needle with the flat side to the back and insert it in the needle clamp. Once it’s up as far as it will go, turn the clamp screw to the right to tighten it.

If your sewing machine needle is bent, dull, or otherwise damaged, it’s time to change it! Here’s how:

1. Loosen the needle set screw.

2. Pull the needle downwards and out of the needle bar.

3. Insert a new needle. If using an industrial sewing machine, turn the needle so the scarf is on the same side as the hook assembly on the machine.

4. Tighten the needle set screw.

What causes a needle to bend?

If you’re experiencing problems with your sewing machine needle bending or breaking, it’s important to first check that the timing is still in alignment. If the machine has been jammed or a needle has been snapped, the timing may be out of sync, which can cause further issues. Once you’ve confirmed that the timing is still good, it’s time to take a look at the fabric you’re using. If you’re pulling the fabric too tightly while sewing, it can cause the needle to bend or break. Try to sew with a gentle hand and be careful not to pull the fabric too tight.

That’s what will snap that needle because the pressure is not even in that needle very much like a straw. If you have a needle that is not sharp, the pressure will be greater on the sides of the needle and it will eventually snap.

Why is my sewing machine needle not picking up the bobbin thread?

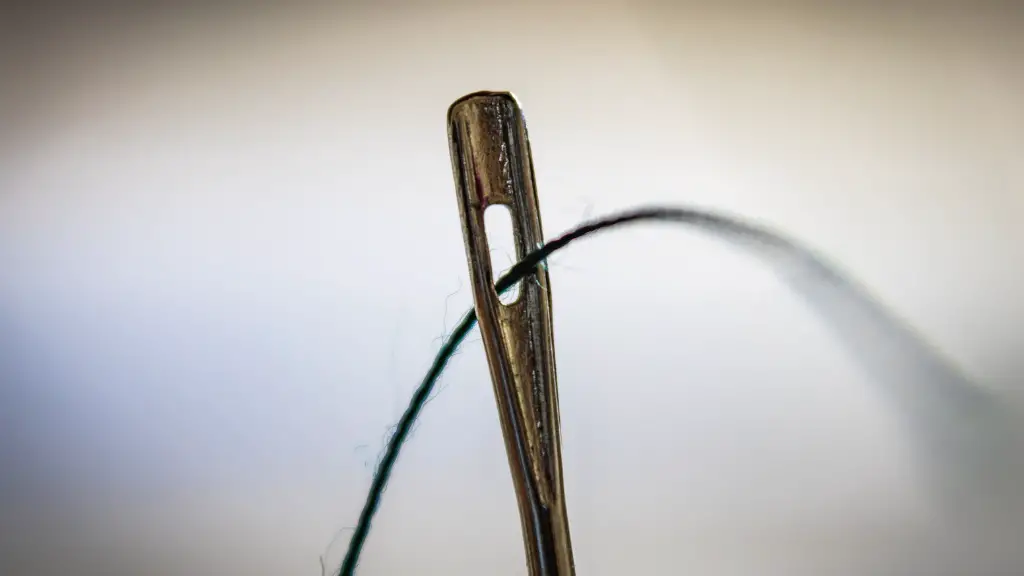

If you’re finding it difficult to thread the needle, it’s likely that you’re holding the needle thread too tight. Try holding the thread lightly to keep the end from going down into the shuttle. Incorrect threading of the needle can also cause problems. Make sure to thread the needle eye from the front to the back.

And then what you’re going to do is push your needle through that loop of thread you just made and pull it tight. You’ve now made a basic knot!

How do you thread a needle that won’t thread

This is a great way to get the thread through the needle if you are having trouble!

If your sewing machine needle breaks, it’s important to take care when removing it and disposing of the broken piece. If not done correctly, it could affect the timing of your machine and cause problems when you try to sew. Be sure to recover all parts of the needle, no matter how small, to avoid any issues.

How do you know if your sewing needle is worn out?

Needles are an important part of your sewing machine and play a big role in the outcome of your project. Damaged or worn needles can result in a number of problems, including broken or shredded threads, skipped stitches, puckered fabrics, and uneven threads. If you hear the needle hitting the machine, needle plate or hook, it’s time to replace the needle.

It’s important to change your needle regularly to ensure the best results. Waiting for it to break or become blunt can cause subpar results. Though it may seem wasteful, changing your needle often is the best way to achieve professional results.

Can you sew with a bent needle

Only use sewing machine needles for home use. Other needles may bend or break and cause injury. Never sew with a bent needle. A bent needle will easily break and cause injury.

If you can see that the sharp point on your knife is becoming dull, it’s time to replace it. A dull knife is more likely to cause injury than a sharp one, so it’s important to keep your knives in good condition.

How do you reshape a needle?

Into that elongated loop and you twist it you just roll it around and around and then when you pull

There are many different types of tapestry needles available, but the most important thing to consider is the size of the needle. The size of the needle will determine the thickness of the yarn that can be used with it. For example, a size 10 tapestry needle can be used with sport weight yarn, while a size 20 tapestry needle is better suited for worsted weight yarn.

Conclusion

If the needle in your sewing machine is not functioning properly, there are a few things you can do to try to fix it. First, check to see if the needle is installed correctly. If not, follow the instructions in your sewing machine’s manual to correct the issue. If the needle is installed correctly but still not working, try cleaning and oiling the machine. If these steps do not fix the problem, you may need to take your sewing machine to a repair shop.

If your sewing machine needle is broken or bent, you will need to replace it. You can do this by following these steps:

1. Unplug your sewing machine and remove the needle.

2.Insert the new needle into the machine, making sure that the flat side is facing the back.

3. Tighten the needle into place and reattach the screw.

4. Plug in your sewing machine and test the new needle by sewing a few stitches.