Understanding tension

When it comes to sewing, tension plays a crucial role in the success of your work. It enables two threads to connect, while keeping a piece of fabric taut and intact. Too little or too much tension can cause your stitches to become loose, too tight, or even misshapen. So, how can you get the right tension on your sewing machine?

Test tension

Before starting on your project, always test the tension of your sewing machine with some scrap fabric or a tension sample. Adjust your upper and lower threads to the ideal level with the stitch plate. Generally, a balanced tension is reached when the upper thread loops from the needle thread to the reverse side. The loop should be between 0.5 cm and 1 cm. If your thread is too long, lower the upper tension and if it’s too short, raise the upper tension.

Practice tension

One of the best ways to get accustomed to tension is to practice sewing on scraps of fabric. This will help to identify whether the right tension is being applied and can also give you a better understanding of the stitch type. If necessary, adjust the tensioning screws and try out different tensions until you achieve the desired result.

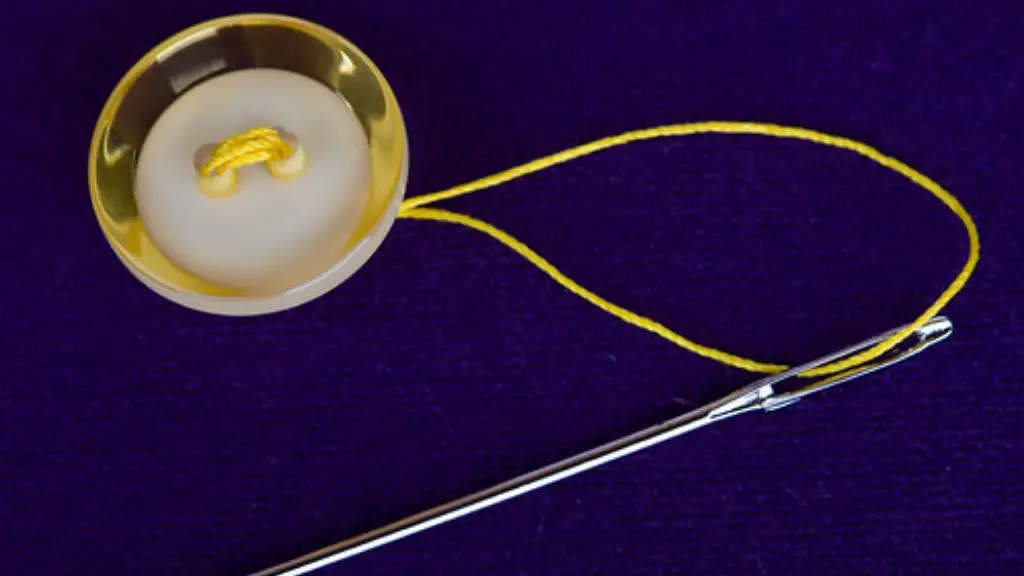

Check bobbin

Another important factor to consider is your bobbin tension. If the tension of the bobbin is too loose, it can cause the needle thread to pull the bobbin thread to the back of the fabric, resulting in a visible loop or messy stitches on the reverse side. To test for correct bobbin tension, drop the bobbin into the bobbinyard without attaching the thread and give the thread a gentle tug. It should therefore be neither too tight nor too loose.

Type of fabric material

It’s also important to take into account the type of fabric you are using. For heavier materials, increase your needle and bobbin tension to tighten the stitch, while for lighter fabrics, use a lower tension to avoid the fabric puckering.

Maintenance and lubrication

In addition to adjusting tensions, it’s also essential to check your machine for regular maintenance and lubrication. Without this, your sewing machine may start to perform poorly and tension problems may arise, so be sure to consult your user manual for tips on keeping your machine in top condition.

Thread quality

Finally, don’t forget to check your thread quality. Low quality, tangled or old thread can also leave visible holes in the fabric or cause stitch problems.

Stitch selection

Selecting the correct stitch type for your specific project is essential to create the perfect outcome. Different types of stitches can require different tension settings, so be sure to reference your user manual and the tension chart of your sewing machine to select the optimum tension and setting.

Tension problems

When tension issues occur, problem areas can often be identified by tracing back to the previous needle. If the problem persists, consult your sewing machine’s tension chart and adjust the tension according to the recommended settings.

Tension spring balance

Tension spring balance is another important factor to consider when ensuring the right tension on a sewing project. If the tension spring is too loose, it will lose tension too quickly. On the other hand, if it’s too tight, it will create stitches with too much tension and create unnecessary and unsightly tension-related issues.

Needle and thread

Be sure to also check that you have the correct needle size and thread for your project. Selecting the wrong needle or thread can be the cause of tension problems. Also, take into account the type of material, thread weight and stitch type you are using.

Proper threading

It’s also important to thread your sewing machine correctly. This includes threading the bobbin, thread guide, presser foot and tension springs. If threading is done wrong, tension can be affected, making your stitching distorted or uneven.

Using stabilizers

Finally, adding fabric stabilizers and backing can also help to achieve the perfect tension. Stabilizers help to hold and support the fabric when stitching, resulting in a neat and even stitch.

Adjusting settings appropriately

Adjusting the settings on a sewing machine can be tricky and time consuming, but it’s essential for achieving the desired outcome with your creations. When setting up your sewing machine it’s important to keep in mind the recommended settings for tension, needle size, and presser foot for the project.

Pressure adjustment

Pressure adjustment is another important factor to consider when getting the perfect tension. If your pressure is too light, it can cause the fabric to pucker, and if it’s too heavy, it can affect the overall tension. To ensure optimal pressure settings, adjust your settings according to the specific fabric density and stitch type.

Using a walking foot

If you’re experiencing tension issues when using thick fabrics, consider using a walking foot. The walking foot helps to evenly distribute tension when stitching and is especially useful when working with layers of fabric or slippery materials.

Checking timing

When all else fails, checking the timing of your sewing machine can often be the missing link to getting the perfect tension. If the timing is off, it can cause tension issues. Fortunately, timing is something that can typically be checked and adjusted easily.

Conclusion

Getting the correct tension on a sewing machine is essential for creating the perfect stitches. By testing tension, practicing, maintaining and lubricating the machine, and selecting the correct settings, you can ensure your project is a success.