Singer sewing machines are a reliable and time-tested tool for those who sew, yet many find assembling the bobbin on these machines a complex task. Learning how to properly install your bobbin can save time and frustration while giving you the confidence you need to complete sewing tasks. This article will provide step-by-step instructions on how to install a bobbin into your Singer sewing machine, along with tips and expert advice for more successful sewing projects.

Before proceeding with the installation of the new bobbin, make sure the presser foot is in the up position, and turn off and unplug the machine from a power source. This is an important safety precaution since moving components can cause injury to another person or yourself, or damage to the machine. Once the machine is turned off, begin by opening the bobbin spindle cover and removing the metal bobbin plate, located beneath the needle plate. This plate can be gently raised up with a flat head screwdriver. Afterwards, release the old bobbin thread casing by pushing in the thin metal shaft found on the right side of the bobbin.

Insert the new bobbin wound with thread into the casing, and loosen the screw slightly to hold it in place. Be sure not to over-tighten the screw, as this can cause strain on the thread or even damage the bobbin itself. After securing the bobbin, pull the bobbin thread gently, until it is wrapped around the tension disc and loop around the drop feed dog located behind the needle. Then, pull the thread through the pre-drilled holes of the metal bobbin cover, while continuing to keep a slight tension on the thread. After pulling the thread out towards the side, cut off excess thread and press the metal bobbin plate back into place for the next step.

Finally, lift the presser foot and slide the needle plate to the back of the needle, and the bobbin is now ready for use. It is important to note that a tight tension is necessary for successful bobbin loading, so be sure to observe the setup of your bobbin thread as you pull it from the casing. Remember to always hold the thread along with the bobbin as to not disturb tension settings within the machine. When you feel certain of the tension settings, attach the thread to the spool pin as normal, and you’re ready to go.

Tips to Thread the Singer Sewing Machine

When it comes to threading a Singer sewing machine, there are several tips and tricks to help ensure a smooth, successful threading experience. First, be sure to use a good quality thread. The quality of thread can significantly affect the performance and lifespan of your machine, so using a higher quality thread is always recommended. Furthermore, be sure to thread the machine slowly and carefully. To save time, it may be tempting to quickly pass the thread through the loops, yet this can cause problems down the line if not done carefully. It’s also important to make sure the thread is firmly in place, as loose thread can lead to tangling or bunching in the bobbin area of the machine.

Additionally, one helpful tip to note is to use a thread stand to keep the thread in place while you pass the thread through the necessary loops and channels. This makes the process much easier and less prone to tangles or bunching. Lastly, keep in mind that your Singer sewing machine has several other loops and channels aside from the threading process that should be kept lint-free and clean. This includes checking the feed dogs, loopers, and blade as well as the various pins, screws, and screws around the bobbin. If need be, a quick dusting of the inside of the machine can go a long way in ensuring the machine runs smoothly.

Resource Guide for Singer Sewing Machines

When it comes to optimal results with your Singer sewing machine, having access to the right resources is key. Thankfully, there are several resources that can help make your sewing experience much smoother and more successful. Depending on the type of Singer sewing machine you own, the available resources may vary. Therefore, be sure to look through the included instruction manual as well as the official Singer website for more specific resources or troubleshooting tips. The Singer website can also provide access to complimentary sewing tutorial videos, educational essays, and information on how to choose the right type of Singer sewing machine.

There are several popular singer-specific instructional books available on the market as well. These books are often filled with a wealth of sewing knowledge and tips for novice users searching for help. It’s important to note as well that there are several forums and online communities dedicated to Singer sewing machines where veteran users and experts can help answer questions and provide helpful advice. In addition, many craft stores or hobby shops have Singer-specific repair or maintenance services available as well.

Common Singer Sewing Machine Troubleshooting

Most Singer sewing machine problems turn out to be quite simple to fix. The majority of the time, it’s a user error or miscommunication that leads to the issue in the first place. Some of the most common issues include the bobbin thread getting caught in the area beneath the needle plate and the spool pin getting blocked or twisted. In the case of bobbin thread getting caught, the tension needs to be adjusted and the needle plate needs to be double checked as well. In the case of the spool pin getting blocked, the machine needs to be unplugged and the blockage carefully removed from around the spool pin.

Singer sewing machines also have safety features in place to ensure circumstances like needle breakage or needle plate damage don’t occur. Once a needle breaks, the machine will indicate an ‘Error 9’ code, which will prompt the user to reset and re-thread the needle. Needle plates can also be damaged if they’re not tightened properly, so be sure to attach the needle plate before continuing with any sewing project.

How to Maintain a Singer Sewing Machine

Though singer sewing machines are reliable tools, they do require periodic maintenance in order to remain in top condition. Studies suggest that certain parts of the machine, like the blade, feed dogs, and loopers, should be cleaned once a month. Furthermore, the machine should also be lint-free and dust-free in order to ensure proper working order. To accomplish this, use a can of compressed air to blow off dust particles without damaging any components. Additionally, lubrication is also suggested during maintenance periods. Use only oils advertised for sewing machines as regular oils can damage the various parts.

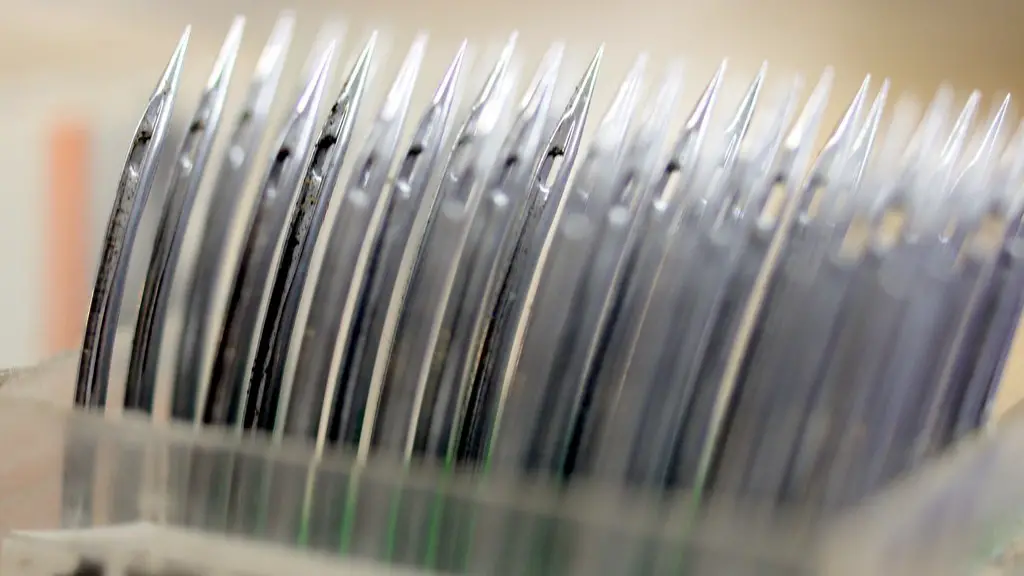

In some cases, the needles, presser feet, and bobbins may need to be replaced periodically as well. Needles become dull over time and presser feet may become worn out due to overuse, while bobbins may need to be replaced if they become damaged or their tension is lost. Be sure to purchase needles and presser feet that are compatible with the Singer model you own, as well as Singer-specific bobbins.

Expert Advice for Singer Sewing Machines

When it comes to learning the proper use and upkeep of your Singer sewing machine, expert advice is essential. Experienced sewers often stress the importance of maintaining tension settings, as well as regularly checking feed dogs, loopers, and other components. Janice Johnson, a professional seamstress with over 15 years of experience, suggests cleaning the feed dogs every time you change fabrics or threads. Johnson states, “The difference between success and failure with a Singer machine is often the feed-, the dirt, lint, and hair accumulation can significantly affect the performance of your machine. To ensure perfect stitches, be sure to make a habit of regularly cleaning the feed dogs—it will make all the difference for optimal results.” Johnson also recommends using a brush or lint remover around the bobbin area and using the compressed air to clean inside the machine.

Additional Precaution For Singer Sewing Machines

In addition to the above mentioned tips, there are a few extra precautions to keep your Singer machine running smoothly. To start, never use an altered or homemade power cord, as this can lead to unsafe operation of the machine. Additionally, avoid operational mishaps or crisis due to unfamiliarity with certain machine components by reading up on the manual or through online tutorials and resources. Most importantly, be sure to use only thread, needles, and fabrics specifically designed for the Singer machine. Using the wrong type of fabric or thread can damage the condition of your machine, leading to more expensive repairs down the line.

Conclusion

Overall, installing a bobbin in your Singer sewing machine doesn’t have to be complicated. With the right resources, expert advice, and maintenance tips, you’ll be well-equipped to use your machine with success. Following the steps outlined in this article, as well as tips from experienced sewers can ensure your Singer machine remains in top condition and provides uncompromisable service for many years to come.