Step 1: Set Up the Sewing Machine

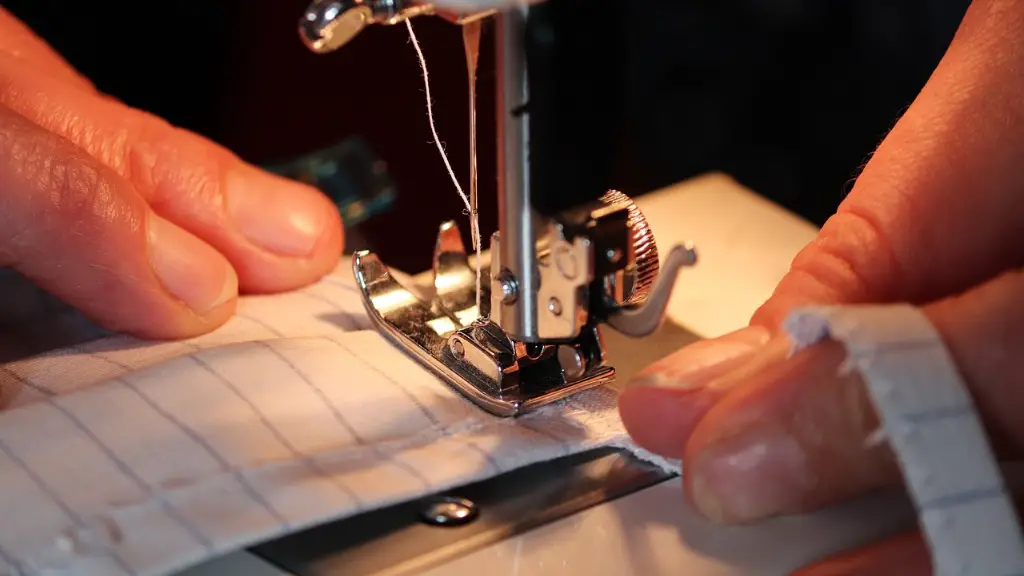

The first step in learning how to lift the foot on a sewing machine is setting up the machine. This includes threading the top thread, inserting the bobbin into the bobbin case, as well as threading the bobbin thread. Make sure the thread tension is properly adjusted as this will greatly affect how the stitch turns out. It is always best to use the manual that came with the machine for any confusion.

Once the machine is set up, it is a good idea to practice on a scrap piece of cloth and make a few stitches. This will help to get the feel of the machine and make sure everything is working as it should before starting a larger project.

Step 2: Raise the Presser Foot

Once the sewing machine is set up and ready to use, the presser foot needs to be raised. This is done by pressing the lever located on the side of the machine. Each machine is different so make sure the lever is pressed in completely. It helps to place the foot in the down position before raising it. This will ensure the foot is up and ready to go.

It will also be important to check the placement of the needle. Make sure the needle is down where it should be and not up as this can cause mistakes and uneven stitches.

Step 3: Getting Ready to Sew

Once the presser foot is in the up position and the needle is placed correctly, it is time to start sewing. It is important to make sure the fabric is not too tight or too loose under the presser foot. It is also a good idea to use a few pieces of masking tape to keep the fabric in place while sewing. This will make a huge difference in the quality of the stitch.

Step 4: Lifting the Presser Foot

Once the sewing is completed, it is time to lift the presser foot. This can be done by pressing the lever once again. It is important to be sure the needle is not stuck in the fabric as this can cause the machine to jam. Once the foot is up, the fabric can be removed and then the next step can be taken.

Step 5: Threading the Bobbin

Once the fabric is removed, it is important to thread the bobbin. This can be done by turning the machine off and carefully threading the bobbin following the instructions in the manual. After the bobbin is threaded, the needle and presser foot can be replaced. It is important to double check the thread tension and make sure it is adjusted correctly so that the stitches are even and the fabric is not puckering.

Step 6: Threading the Needle

After the bobbin is in place, it is time to thread the needle. This should be done with the machine off as this will provide better control. Use the threader that came with the machine to pull the thread through the eye of the needle. Make sure to thread the needle from left to right for best results.

Once the thread is through, turn the machine back on and check to make sure the thread is pulled up to the top of the needle. If it is not, press down on the foot pedal several times until it is. This will provide a better grip on the fabric and create even stitches.

Step 7: Start Sewing

Once the needle is threaded and the presser foot is in place, it is time to start sewing. Place the fabric under the presser foot, making sure it is in the right position. Then, press the foot pedal and start sewing. Be sure to keep the fabric in place and to hold the thread tails so that they don’t get tangled in the fabric.

Step 8: Lower the Presser Foot

Once the sewing is complete, it is time to lower the presser foot. This can be done by pressing the lever on the side of the machine once again. Make sure to hold the thread tails as the presser foot is lowered as this will prevent them from getting tangled in the fabric.

It is important to double check the stitch length and tension before starting to sew again. If the stitch length is too short or the tension is off, it can cause problems with the stitching. Be sure to adjust the settings accordingly to get the best results.

Maintenance and Safety

It is also important to keep the machine clean and pay attention to the maintenance instructions provided with the machine. This will help to keep the machine running smoothly and prevent any damage from occurring. It is best to lubricate the machine with a sewing machine oil every few months to keep the parts working properly.

Safety is also an important part of using a sewing machine. Make sure to read the instructions and any warnings on the machine before using it. It is also a good idea to wear safety glasses when working to protect against any debris or sharp needle points.

Common Problems

One of the common problems that arise when learning how to lift the foot on a sewing machine is an uneven stitch. If the tension on the needle thread is too tight or too loose, this can cause the stitch to be uneven. Double checking the tension will help to resolve this issue.

Another issue that can arise is fabric puckering or shifting. This can be caused by fabric that is too tight under the presser foot or if the needle is inserted at an angle. Making sure the fabric is placed correctly and the needle is vertical will prevent this issue.

Tips and Tricks

There are a few tips and tricks that can make learning how to lift the foot on a sewing machine easier. Using stabilizer on slippery or difficult fabrics, or even a piece of tissue paper underneath the fabric can help keep the fabric in place. It will also help to use a few pieces of masking tape on the edges of the fabric to keep it from shifting.

Another tip is to practice on scrap pieces of fabric before starting a larger project. This will help to get used to the machine and to make sure everything is working correctly. It will also make it easy to adjust the settings as needed when starting with a smaller project.

Tips on Troubleshooting

If any issues or mistakes arise while sewing, it is important to troubleshoot. Sewing machines can be delicate and need to be handled with care. Common mistakes such as skipped stitches, tension problems, or fabric shifting can all be fixed with a few adjustments.

It is always best to refer to the manual for any problems as it will have all of the information needed for a successful repair. If the manual does not provide the answer, seeking help from people familiar with the machine may be necessary.

Tips for Stitching Different Fabrics

Different fabrics require different stitching techniques in order to get the best results. For thick fabrics, a walking foot may be needed in order to evenly feed the fabric through the machine. For lightweight fabrics, a special needle may be needed to prevent piercing or damage to the fabric.

It is important to do a test stitch on a scrap piece of fabric before starting a project in order to make sure the settings and technique is correct. After the test stitch, the fabric can be adjusted or removed and the stitch tension can be adjusted if needed.

Conclusion

Lifting the foot on a sewing machine is an important skill to learn in order to produce quality projects. It is a simple process but it is important to take the time to learn the proper technique in order to avoid any problems. With a bit of practice and patience, the process can be mastered in no time and the results will be professional quality projects.