Seam Preparation

Dressing up an outfit with a thread singer sewing machine used for mending repairs or creating a unique piece of clothing can make the task easier and lead to better results. Before we start learning how to thread a singer sewing machine, it is important to make sure that the desired fabric is in the right condition. Check the fabric for any wrinkles and see whether or not it has been pre-washed. Seam allowance should also be considered when measuring and cutting the fabric. It is beneficial to mark the fabric with tailor tacks if needed to indicate the most important points before starting to sew. Also, during the seam preparation, press the fabric with an iron to give it a smooth finish.

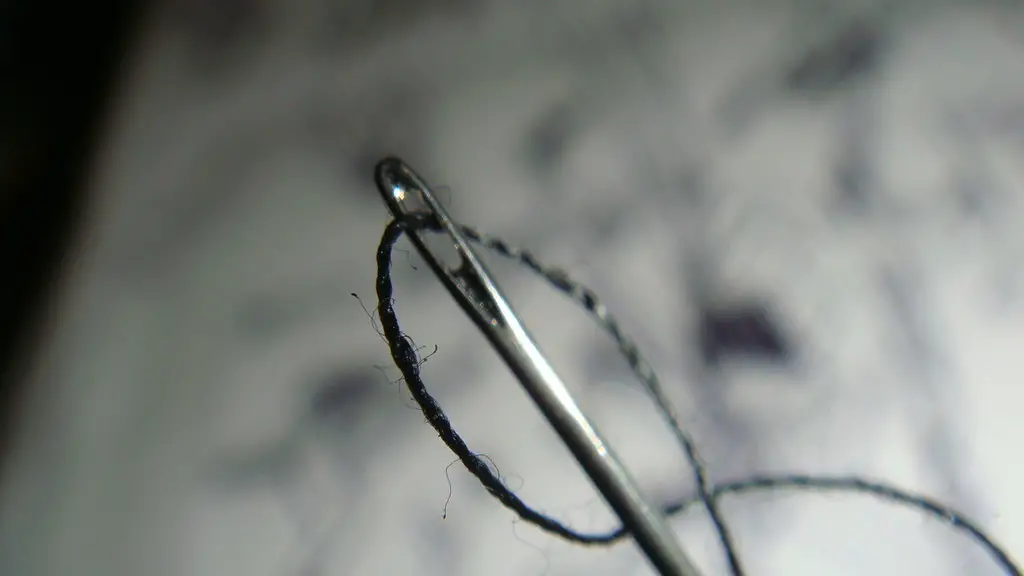

Threading the Machine

Once the fabric preparation is complete, we can start threading the singer sewing machine. Firstly, thread the spool of thread onto the spool pin at the top of the machine and make sure to wind it tightly. Secondly, pull a length of thread from the spool and thread it through the upper tension disk on the inside of the machine. Pull the thread up through the thread guide and then down through the take up lever. Once complete, lift the needle up to its highest position and thread it through the eye of the needle. Finally, pull the thread down through the lower tension disk and across the bobbin tension before guiding it through the bobbin case. When the threading of the singer sewing machine is complete, the threads can be secured by pulling them to the back of the machine.

Inserting the Bobbin

The bobbin is the part of the singer sewing machine used to hold the lower thread when sewing. To correctly insert the bobbin into the machine, the bobbin should be placed in the same direction as indicated by the arrow. With the bobbin case attached to the bobbin, the next step is to thread the bobbin case with the lower thread. Pull the thread from the side of the bobbin and thread it through the small slot of the bobbin case. After drawing the thread around the tension spring, a loop of thread should be brought up through the hole between the tension spring and the bobbin case. Finally, insert the bobbin case making sure not to twist the thread in the case.

Adjusting Tension

Adjusting the tension of the singer sewing machine is a crucial step in the process of threading. To adjust the upper thread tension, begin by turning the tension adjustment dial on the top right side of the machine towards the plus sign. To adjust the lower thread tension, turn the bobbin tension adjustment dial counter-clockwise until a small click is heard and the needle can be pulled through fabric with ease.

Stitching Techniques

Once the singer sewing machine is threaded and the tension is correct, it is time to begin with some basic stitching techniques. To start sewing, place the fabric under the foot and begin by placing the needle into the fabric. The thread from the upper side should be pulled through the fabric before the foot pedal is pressed down. This will cause the needle to ‘catch’ the fabric and move up and down depending on the pressure of the foot pedal. Sewing continued stitches is made simpler by using the reverse switch on the top of the machine to secure stitches in place. Increasing the stitch length is also recommended before starting a new line of stitches.

Using Appendages

When learning to thread a singer sewing machine, it is also important to familiarise oneself with the various appendages that come with the machine. The most common appendages are the zigzag foot, presser foot, quilting foot, zipper foot and button sewing foot. The zigzag foot is used for regular stitching, the presser foot for making garments, and the quilting foot for patch work and quilting. The zipper foot is used for attaching zippers on garments, and the button sewing foot is used for attaching buttons. When using these different feet, adjust the presser foot accordingly in order to move the fabric without any interference from the foot.

Understanding Seam Finishes

Having knowledge of the different types of seams and seam finishes is important when threading a singer sewing machine. The most common types of seams include straight seams, French seams and flat felled seams. Straight seams are the most basic type of seams and are made with a single line of stitches. French seams are used when joining two pieces of fabric together and closing the edges simultaneously. While flat felled seams are generally applied to finish the seam allowances of trousers and jeans. Seam finishes also include neatening the seams with overlocking or bias binding. Overlocking is a technique used to close fabric edges with a serger, and bias binding is used to enclose the raw seam edges with a bias tape.

Fabric Selection

Fabric selection is a crucial aspect of designing a garment with the singer sewing machine. The weight and structure of the fabric will decide the type of needle to be used and the stitch length to be applied. While bulky fabrics will require a sharp needle and shorter stitch length, lightweight fabrics will require a ballpoint needle and longer stitch length. Cotton fabrics and linen fabrics are suitable for light to medium weight items, while wool fabrics and denim fabrics are suitable for heavier items. It is also important to consider the stretch of the fabric when selecting a fabric for a particular project.

Other Techniques

Other than the basic techniques, there are a few more techniques that come in handy when threading a singer sewing machine. Gathers are made by creating ease in the garment and squeezing the fabric before stitching. Pleats can be made by folding the fabric at a right angle and then folding it back on itself with a line of stitches. Sewing darts involve drawing out fabric on pattern pieces in order to make an intended shape or feature. Ease stitching is another important technique used in pattern drafting for loose fitting garments. And finally, using embroidery floss or hand stitching techniques to create special effects on garments can create a unique look.

Equipment Maintenance

It is also important to understand how to properly maintain the singer sewing machine. When the machine is in use, yarn bits and fabric particles can accumulate in the feed dogs and bobbin case. Therefore, it is necessary to clean these parts regularly with a soft brush or rod. The needle should also be regularly replaced in order to ensure smooth stitching. To be specific, the needle should be changed after every 8-10 hours of use. Finally, regular oiling with the right oil and in the right places will help extend the life of the singer sewing machine.