Needle Lifting Basics

Sewing machines are a huge technological advancement in the fashion industry, allowing for streamlined process from designing to production. A crucial element of any machine is the needle, so it is important to understand proper technique for needle lifting mechanism. Improper technique can damage or degrade the quality of work, but with a few simple steps, raising the needle can be done safely and efficiently.

Needle Lifting Explained

Raising the needle is done in order to reset the position of the needle to stitch in a different spot or to ensure the fabric is safely removed from the machine. On traditional sewing machines, a presser foot lever raises and lowers the needle. On modern digital machines, the needle is raised and lowered using the computerized display. It is important to remember, no matter which type of machine, the needle is always supposed to be resting on the fabric before the sew line is completed.

Needle Lifting Safety Pointers

First and foremost, make sure the needle is not attached to your hand or clothing before attempting to raise it. It is also important to turn off the machine before beginning the reset procedure and always keep both hands clear of the needle and presser foot for safety. After turning off the machine, test the needle lifting mechanism by engaging and disengaging the presser foot lever or pressing the raise needle button a few times to ensure it is working correctly.

Operational Steps

Once the above steps have been completed, then proceed with raising the needle. On digital machines, the needle should be lifted to its highest position while the presser foot is in the lifted position. On traditional machines, position the needle at its highest point, then engage the presser foot lever to the lifted position. After the needle has been lifted, use a small screwdriver and adjust the needle height, if required, for the next sew line. Once the needle is properly positioned, you can power up the machine and proceed onto the new stitch pattern.

Maintaining the Needle

Ensuring the needle is in good condition and getting regular cleanings is also a good way to ensure the longevity and integrity of the needle. Dirt and dust can accumulate in the needle and lower the overall performance and quality of the stitches, so it is highly recommended to frequently inspect and clean the needle. This can be done by using a dry toothbrush to carefully brush away any debris or dust.

Adjustment Tips

Sewing machines for thicker fabrics, such as denim and upholstery, require a Needle Plate Screw adjustment. When the machine is sewing too close to the needle plate, the needle plate needs to be adjusted. This can be done by unscrewing the screw that holds the needle plate and sliding the plate to the left to create a larger space for the needle. Re-tighten the screws securely, and test the machine before continuing.

Bobbin Techniques

Bobbins are a key part of any sewing machine, regardless of type or model. It is important to note that not all bobbins work with all machines, as some models may require a particular bobbin design to function correctly. When changing bobbins or testing new ones, always lift the needle and keep the machine off to prevent possible damage to the machine or fabric.

Stabilizer Strategies

To ensure the fabric stitching is well-secured, the stabilizer is a crucial part of most sewing projects. Stabilizers come in many shapes, sizes and materials and serve as extra support for the design which will determine the quality of the final product. Regular stabilizer testing to ensure the integrity of the stitching is also recommended with any project, as stabilizers can wear out over time.

Checking for Burrs

If the fabric is being caught, puckered or torn, inspect the needle for burrs. Burrs are tiny pieces of metal on the needle that can snag or tear the fabric as it is being fed through the machine. To inspect the needle, use a strong magnifying glass and slowly roll the needle between your fingers. If burrs are present, the needle needs to be replaced with a new, sharp needle in order to have a successful sew line.

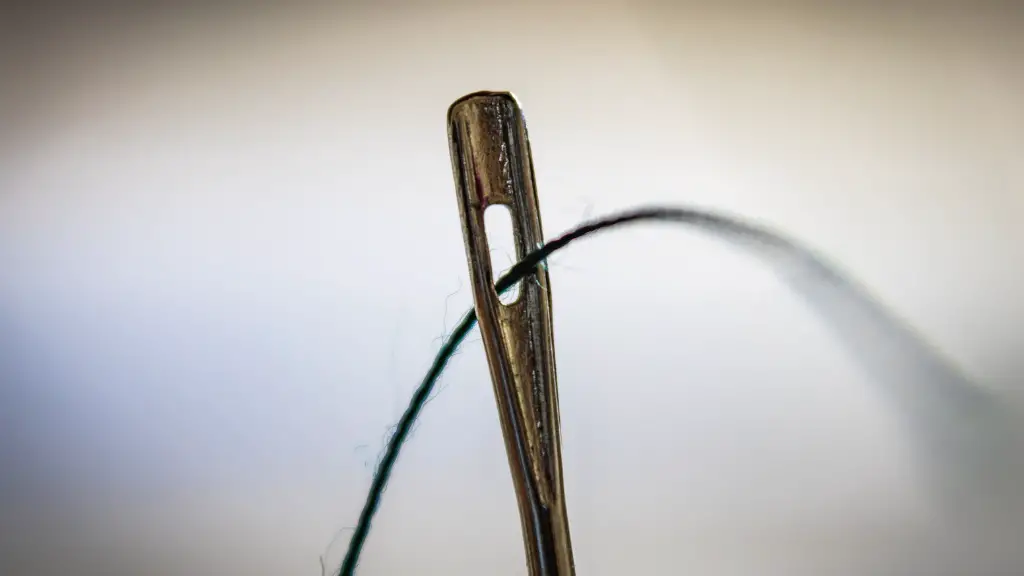

Threading Tips

Threading the machine correctly is essential for great quality stitches, so always double check the thread to make sure it is properly secured before proceeding. Threading the machine too tightly can cause tension problems, so it is important to leave enough slack in the threading before threading the needle. Post-threading, always test the threading on a scrap piece of fabric before starting a project.

Selecting the Right Needle

To ensure the project is sewn to the best quality and standard, it is important to select the right needle for the fabric type. There are many varieties of needle types, so be sure to read the description carefully when choosing a needle. Needles range in size, type, point, material and more, so using the right one will guarantee successful stitching.

Alternating Threads

Alternating threads are also a great technique to ensure the best stitch outcome possible. This can be done by threading both the upper and lower portion of the machine with two threads of different colors. This will create a more vibrant design and also offer more protection for the stitching, as there will be more thread in each stitch.